Baoji Yumingda Metal Materials Co.,LTD.

Titanium target is a special material mainly used in physical vapor deposition (PVD) technology. Sputtering coating refers to the process of bombarding the surface of the target material with functional particles (such as argon ions) under vacuum conditions, so that the surface atoms of the target can obtain enough energy and escape. Suitable for flat plating, such as: mobile phone back shell, frame, plate, etc.

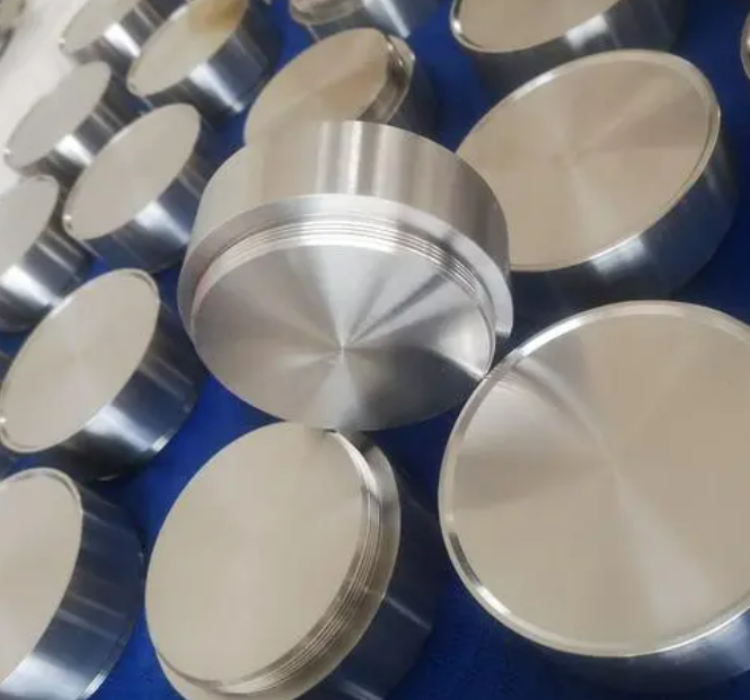

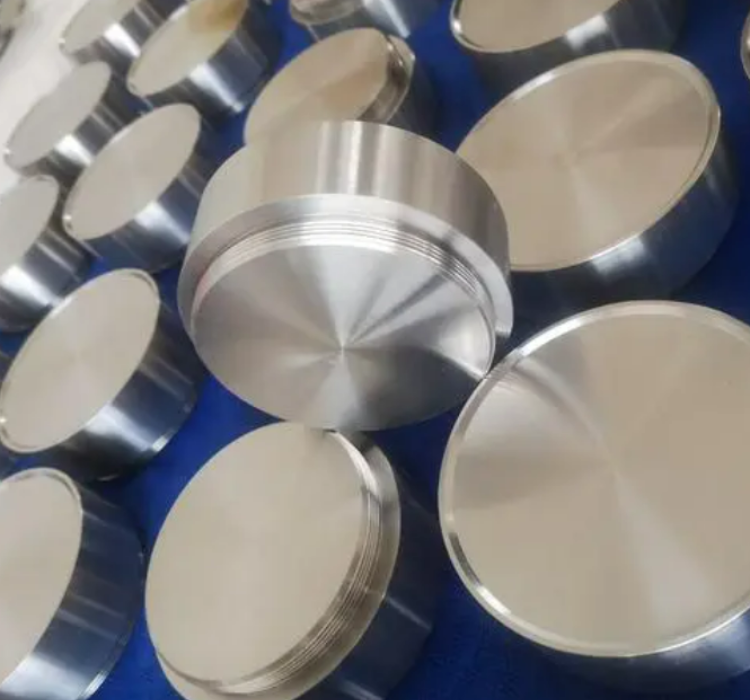

The titanium target material is made of pure titanium or titanium alloy as the main component and is made by fine manufacturing.

High density

Smelting equipment technical modification target density increased to 95-99%

High purity

Special raw material impurity content low purity increased to 99.99%min

High precision

Precision CNC machine with center tolerance of 0.1mm surface roughness 32Ra

Titanium target is a high purity titanium or titanium alloy slab material made by vacuum melting and investment casting process. Its most notable properties are high purity and excellent densification. The density of high-quality titanium targets can reach more than 99.5%, and the impurity elements are very low, such as Fe, Si, O, N, H and other elements are less than 100ppm.

In addition, the titanium target has excellent uniformity. In the preparation process, three melting and heat treatment were used to effectively improve the microstructure uniformity of the titanium target.

Titanium target main uses:

Laser sputtering:

Prepare the surface hardening layer of mechanical parts to improve the wear resistance.

The surface coating of biomedical titanium alloy material was prepared to improve the biocompatibility.

Arc evaporation:

The transparent conductive film of the front electrode of solar cell was prepared.

The titanium base reinforced layer of the composite was prepared.

Iii. Preparation method of titanium target material

Metallurgical process

Principle: High purity titanium is smelted by vacuum arc smelting and other technologies, and then titanium targets are made after multiple melting and quenching, cold rolling or forging.

Process flow: material selection → melting → quenching and forging → machining → testing

Advantages: High density of titanium target material, high purity, good uniformity.

Disadvantages: complex process, high energy consumption, high cost.

purity

The film prepared by high purity titanium target (such as 99.99%) has high purity and good performance. But the target material wears out quickly, increasing the operating cost. Although the low purity titanium target has cost advantage, the impurity content of the deposited film is high, which affects the film performance.

density

The high density titanium target film has good density and strong adhesion. However, too high density will also increase the stress in the film. Titanium target with moderate density can obtain a film layer with balanced properties.

Surface roughness

The bright and flat titanium target can deposit a film with better surface quality. But too much polishing can also cause particle shedding problems. Moderate surface roughness helps to improve the adhesion of the film.