In our previous introduction to laser cutting of titanium materials, we know that laser cutting will generate heat, resulting in oxidation of the cutting surface. And thermal deformation of the product. In order to solve the above problems, Umingda Metal introduced water cutting technology.

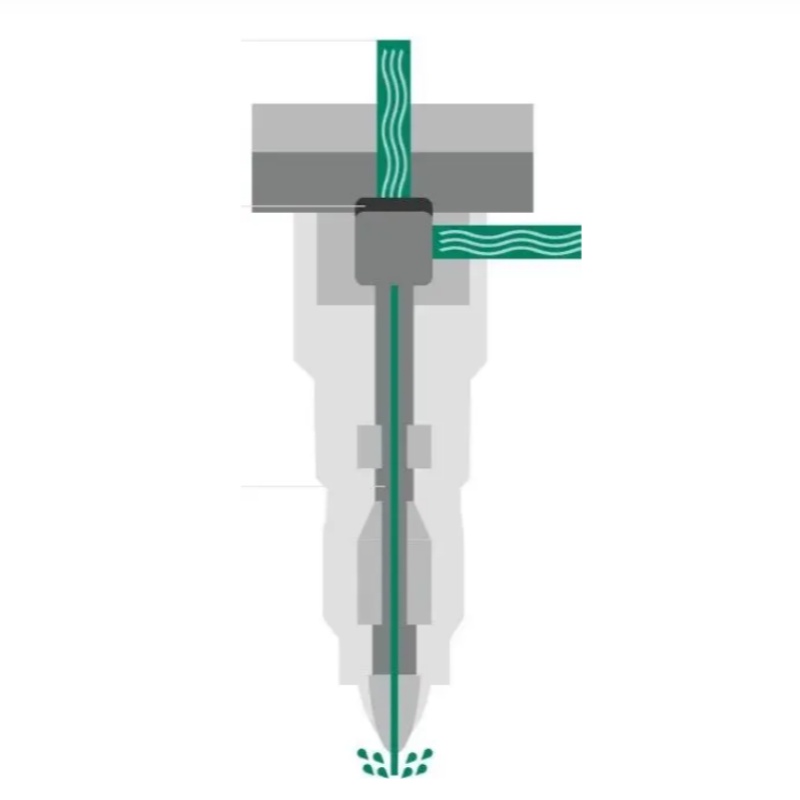

Water cutting processing: Using ultra-high pressure technology, ordinary tap water can be pressurized to 250-400Mpa pressure, and then through the inner hole diameter of about 0.10-0.35mm gem nozzle. The jet forms a high-speed jet with a speed of about 800-1000m/s, commonly known as a "water knife". The "water knife" has a high energy and can be used to cut soft base materials.

Titanium water cutting is generally in the "water knife", adding an appropriate amount of abrasive such as quartz sand, emery, etc., to enhance the cutting force.

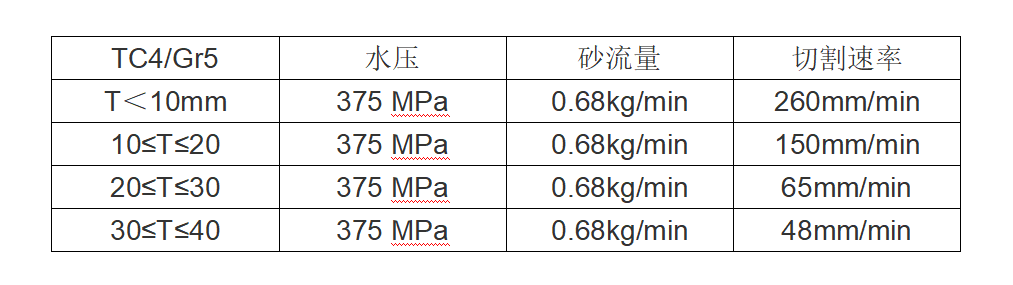

When titanium material is cut by water cutting, it is perforated first, and then cut by the knife at a certain speed, and finally the remaining energy of the sand flow is contained by the collector and the water knife is dispersed during cutting. It is not difficult to see from the principle of water knife cutting that water pressure, sand flow and cutting rate are crucial parameters that affect the quality of material cutting.

According to the experience of Umingda metal cutting experience. According to the TC4/Gr5 plate as an example, the following table is made:

Advantages of titanium water cutting technology: water cutting technology is a cold processing method, with low workpiece temperature, no heat affected zone, no heat deformation during cutting.

The disadvantage is that:

Due to the use of high pressure water flow, the gem nozzle of water knife equipment has a large loss and needs to be replaced in time.

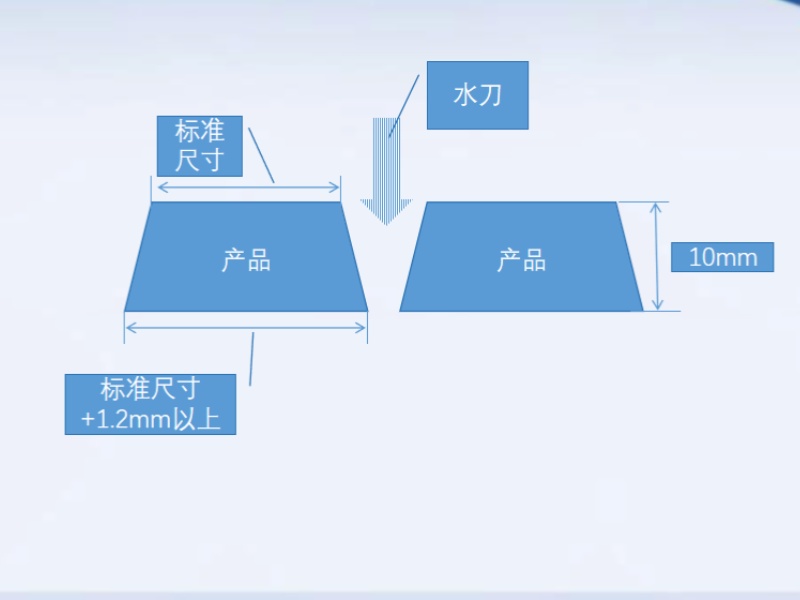

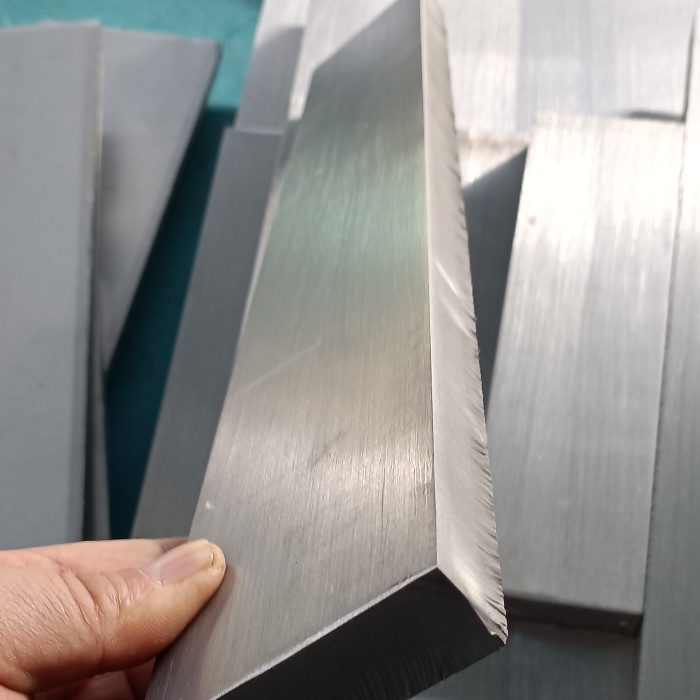

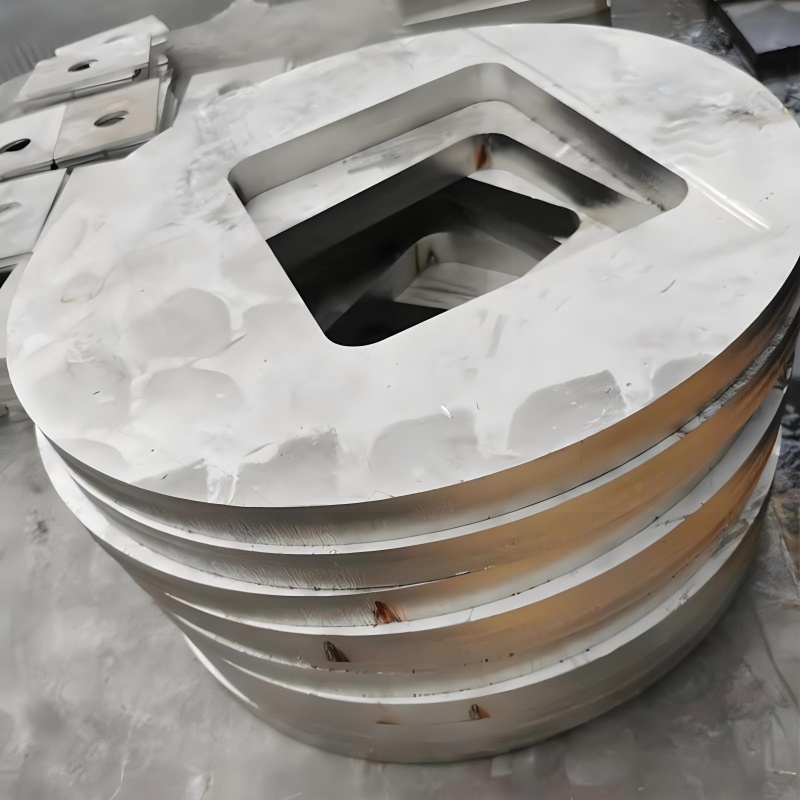

Residue at the cutting edge of the cutting surface: for excessively thick titanium plates. For example: more than 10mm sheet will appear inclined (see diagram).