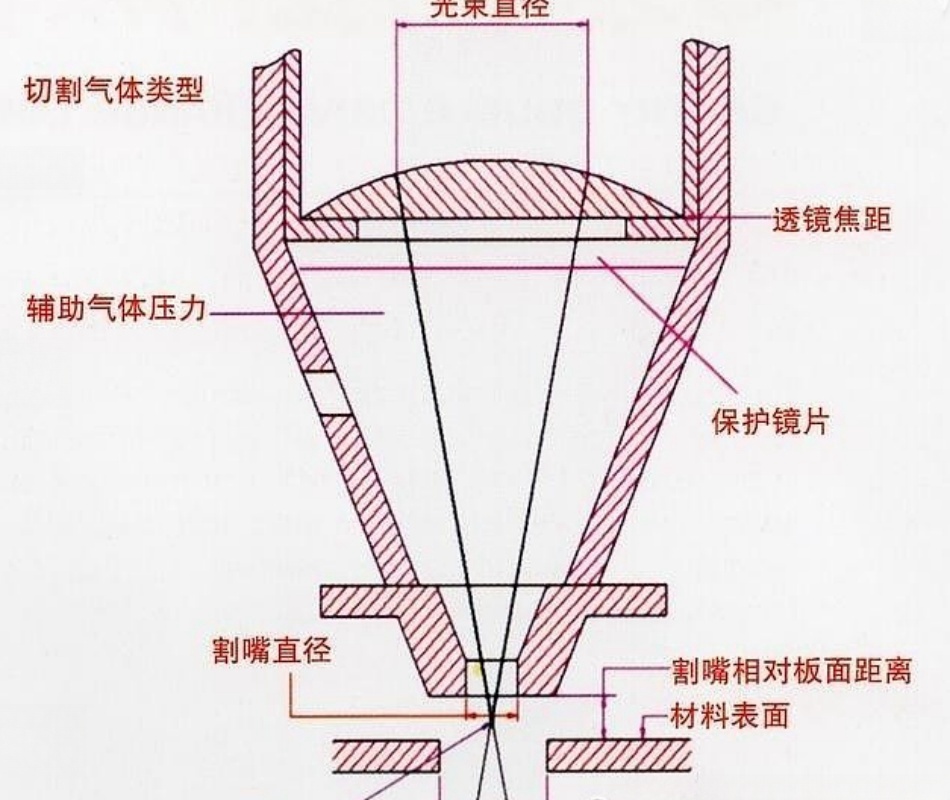

Laser cutting is the use of a focused high-power density laser beam to scan the surface of the workpiece, in a very short time to locally heat the material to thousands or even tens of thousands of degrees Celsius, so that the irradiated material quickly melted, vaporized, cauterized or reached the ignition point, and at the same time with the beam coaxial high-speed air blowing molten material, to achieve the workpiece cut, to achieve the purpose of cutting materials.

According to experience, the main factors affecting the effect of laser cutting:

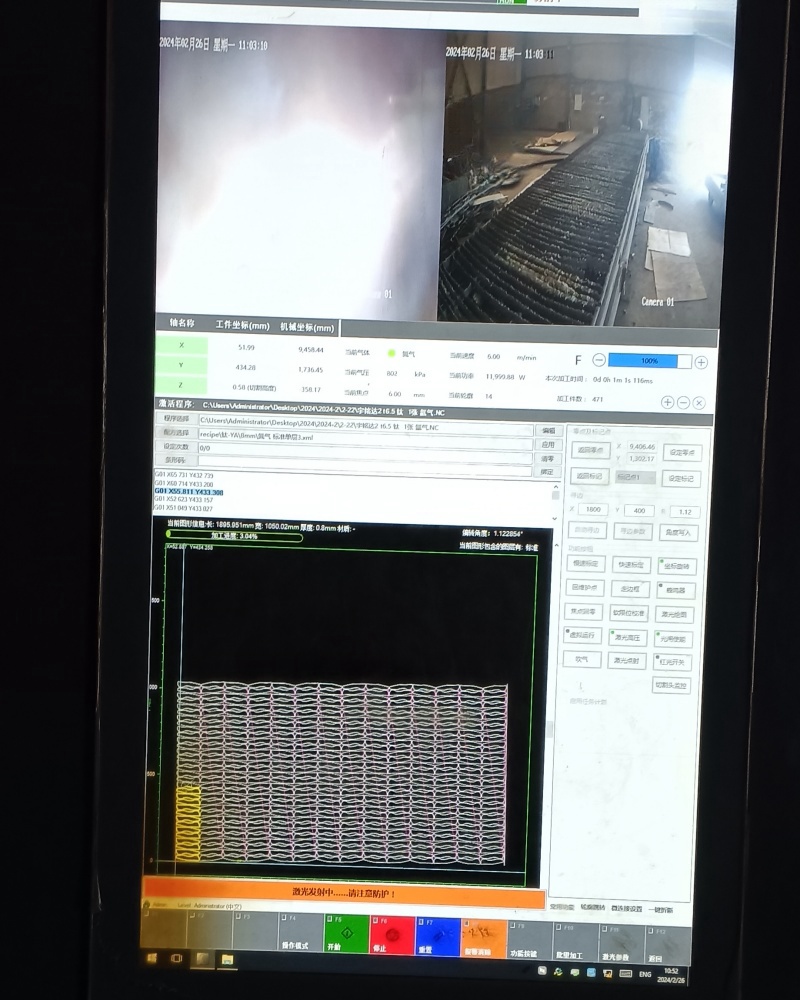

1 Laser cutting process parameters

The parameters to measure the laser cutting process and machining quality mainly include laser power.

2. Cutting speed

The laser cutting speed is affected. Generally speaking, the higher the laser energy, the smaller the material thickness, and the greater the cutting gas pressure, the faster the cutting speed, and vice versa.

In the field operation, the laser cutting speed should not be blindly pursued, but the laser cutting quality should also be taken into account. Especially for some mechanical parts of the opposite shape, speed and quality should be balanced to ensure product quality.

3. Gas pressure

Laser cutting and blowing gas has the following functions: first, it is used to melt and cut metal materials and rely on the pressure of the gas to blow away the liquid metal to form a incision; The second is the cooling effect of gas on raw materials, which can take away part of the energy from the cutting zone. Therefore, the gas has an important effect on the cutting quality.

When titanium materials are processed, inert gases (argon or nitrogen) are needed to reduce the problem of oxidation pollution.

The impact of laser cutting on the finished product of titanium material:

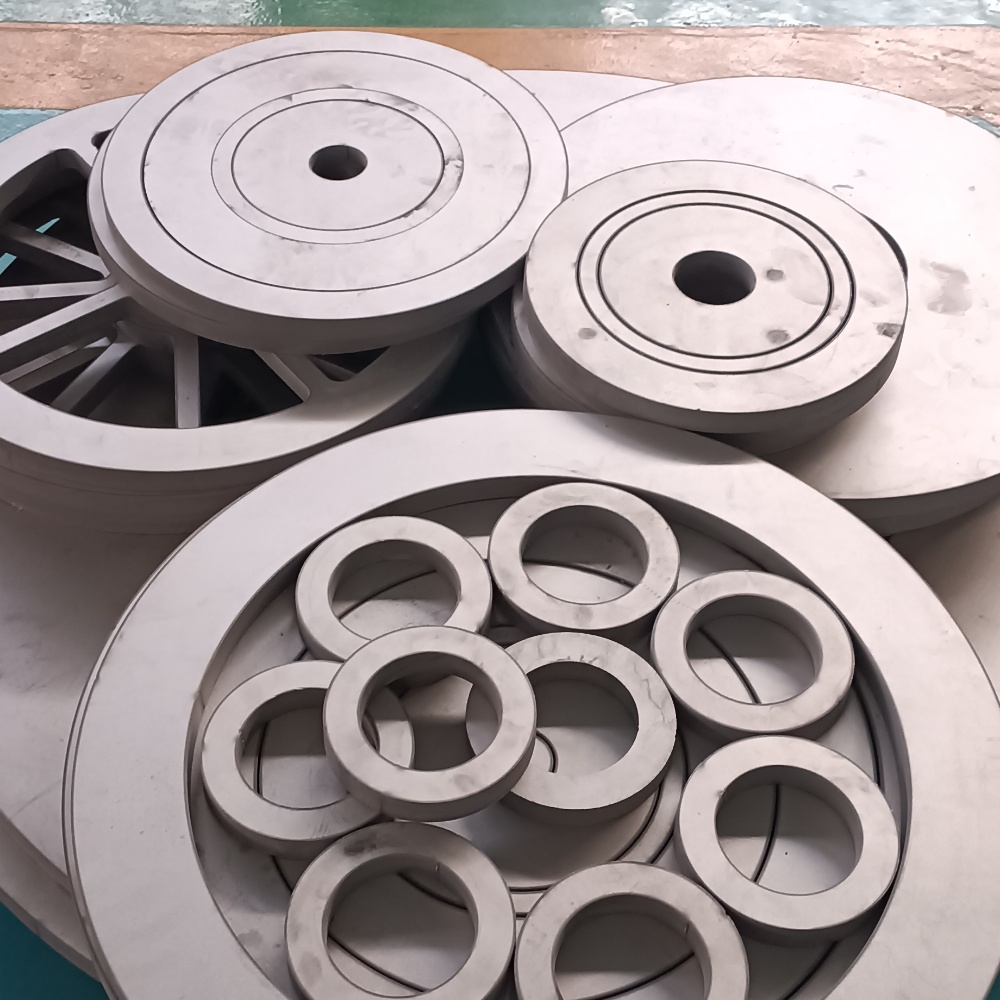

1 Raw edge. Titanium laser cutting generally uses argon or nitrogen as an auxiliary gas, which will produce a little sticky slag at the bottom of the slit, but it is easy to remove, and the cut will produce a hard and brittle oxide layer due to the absorption of oxygen.

2 Deformation. Because titanium material cutting generates a lot of heat, the product is lengthened with processing time. The first product and the last product have different amounts of deformation. If the heat can not be reduced in time, it will cause deformation of the product.