The most original name for forging is: blacksmithing. The blacksmith shop of the old Wang couple at the end of the village is ding-dong, which is also a form of forging.

Lao Wang and his wife make iron

Forging is a processing method that uses forging machinery to exert pressure on metal billets to produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes, and one of the two components of forging (forging and stamping).

8000 tons forging machine

The purpose of forging: through forging to eliminate the metal in the smelting process of the as-cast loose and other defects, optimize the microstructure, while due to the preservation of a complete metal flow line, the mechanical properties of the forging is generally better than the same material castings. For important parts with high load and severe working conditions in related machinery, forgings are mostly used in addition to plates, profiles or welding parts with simple shapes that can be rolled.

In my opinion: forging is like kneading flour in the process of processing pasta by old mother. Kneading is to mix the water and flour added to the flour evenly, the protein and other nutrients dispersed in the flour, after uniform water absorption, gradually condensed to form gluten, under the action of gluten, the formation of a network structure, so as to wrap the gas produced during fermentation, forming a fluffy tissue.

Mom kneads dough

Now, Yu Mingda metal materials briefly talk about titanium and titanium alloy free forging. Divided into four processes:

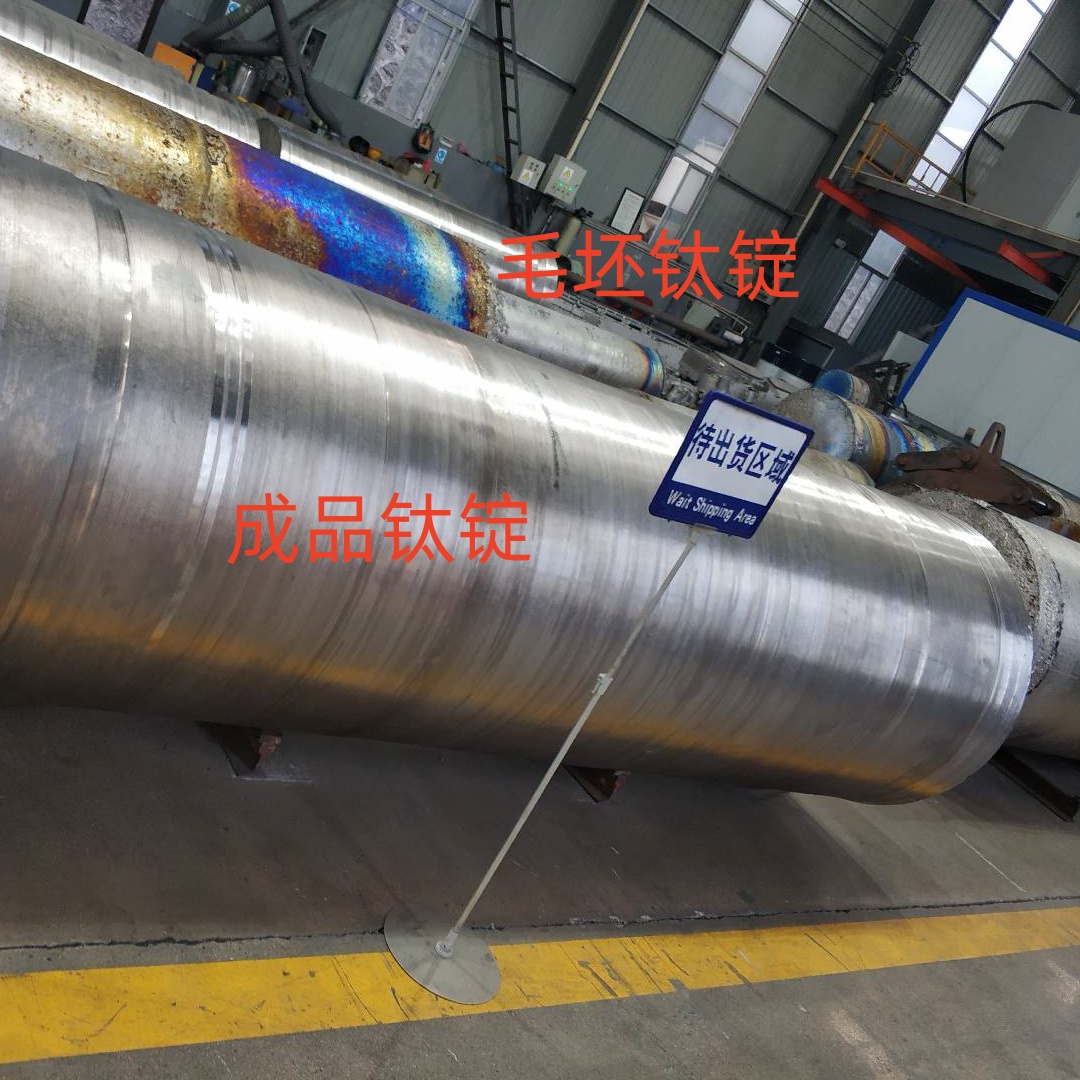

1. Material preparation: Titanium and titanium alloy need to be polished into finished titanium ingot after melting, and cut off the riser end.

3 tons of finished titanium ingot

2. Heating: the titanium alloy blank is heated to the appropriate temperature, generally the β phase temperature (850 ° C ~950 ° C), so that it can achieve a state of plastic deformation. This process is important because titanium is sensitive to temperature.

Titanium ingot heating completed

According to production experience: generally 3 tons,φ640MM TC4 titanium ingot. It takes 5.5 hours to heat to the specified temperature. It is divided into: heating, to temperature, heat preservation, and four sections of the oven, and it is necessary to make detailed records.

Forging: Put the heated titanium alloy blank into the forging machine for forging. Control the temperature, deformation (30%~50%), do not hammer the material flat. First pull the length, then pier back, three pier three pull, break the metal in the smelting process of the as-cast loose and other defects.

Titanium ingot forging

Cooling: After forging, the superheated titanium alloy blank is air-cooled to room temperature to increase its strength and toughness. There are other cooling methods: water cooling, air cooling, oil cooling, and cooling with the furnace. That is the knowledge of quenching, today will not be detailed.

Titanium is cooled in the air