Around 2000, the EU began to conceive the implementation of the "RoHS Directive" and "WEEE Directive", and electroplating products were in urgent need of alternatives. So began to contact PVD technology instead of electroplating.

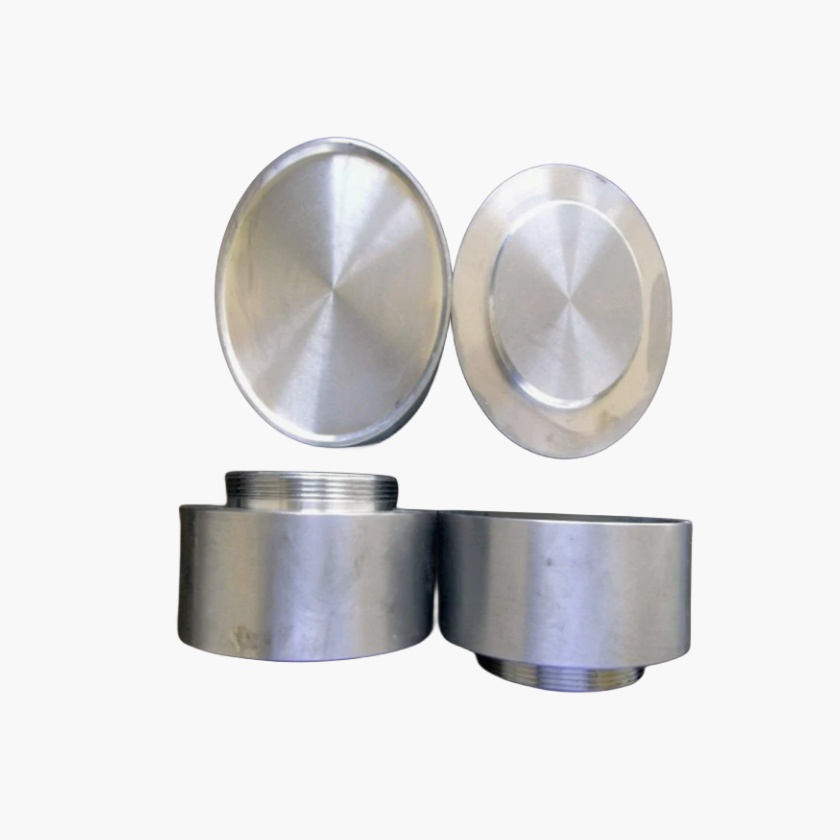

The titanium target is a round or square shape made of pure titanium or titanium alloy. "Target" is a term used here primarily in areas involving physical evaporation or sputtering processes where titanium targets provide the base material for the coating of products as targeted materials.

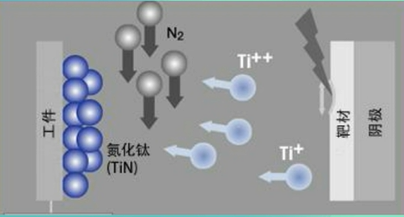

Physical Vapor Deposition (PVD) technology refers to the physical method of bombarding the surface of a material source (solid or liquid) under vacuum conditions to vaporize into gaseous atoms or molecules, or partially ionize into ions, and through a low-pressure gas (or plasma) process. Physical vapor deposition (PVD) is one of the main surface treatment techniques for the deposition of a film with a special function on the surface of a substrate. At that time, the most contact was aluminum target, titanium target, gold target, etc., and only knew that the target was particularly expensive.

Today we mainly discuss the titanium target, titanium target contains pure titanium and titanium alloy. The titanium target has the excellent characteristics of titanium itself, such as excellent corrosion resistance (acid and alkali resistance), high strength and low density, as well as good biocompatibility, high temperature resistance and so on. The target is "bombarded" during the PVD process to produce titanium atoms, so its surface quality has a great influence on the quality of the deposited titanium film. Therefore, the target material usually needs to be polished to achieve a surface that is sufficiently flat and free of microscopic cracks and impurities. In this way, high sputtering rate and high purity of the film can be guaranteed during use

Manufacturing process of titanium target material

Titanium sponge pick (high purity titanium sponge 4 n, 4 n5, 5 n) - vacuum melting (VAR) three times (melting) - forging - rolling - rough machining - heat treatment - finishing - the third party inspection quality inspection -- -- -- -- -- -- the packing (vacuum packing) - shipments

Application field of titanium target

1 Semiconductor industry: titanium and its compounds (such as titanium nitride and titanium oxide) are often used to manufacture interface layers, welding membranes, barrier layers, etc., in semiconductor equipment. It can be used to deposit metal films on silicon wafers, which are used to connect other electronic elements to form circuits.

2 Coating Industry: Titanium targets are used for physical vapor deposition (PVD) and chemical vapor deposition (CVD) to produce efficient and durable coatings. These coatings are used in a number of fields, including solar control glass on buildings, wear-resistant hard films for automotive parts, and corrosion-resistant films for fossil energy equipment.

3 Optical Industry: In the optical industry, titanium targets are used to manufacture thin films with properties such as anti-reflection, wear consumption and oxidation protection. Some specific applications include glasses coatings, camera lens elements, telescopes, microscopes and other precision instruments.

4 Storage device: In data storage devices, such as hard disks, the magnetic row layer of hard disks usually uses a thin titanium film, which has good thermal stability and wear resistance.

5 Medical device industry: In the dental field, PVD technology can be used to deposit titanium films on dental implants to enhance the bonding force with bone and improve biocompatibility.