Mention melting, it is reminiscent of the common smelting of iron, hot iron in boiling. Mars is a spectacular sight.

In fact, the chemical properties of titanium materials are active and easy to react with oxygen, nitrogen, and so on in the air.

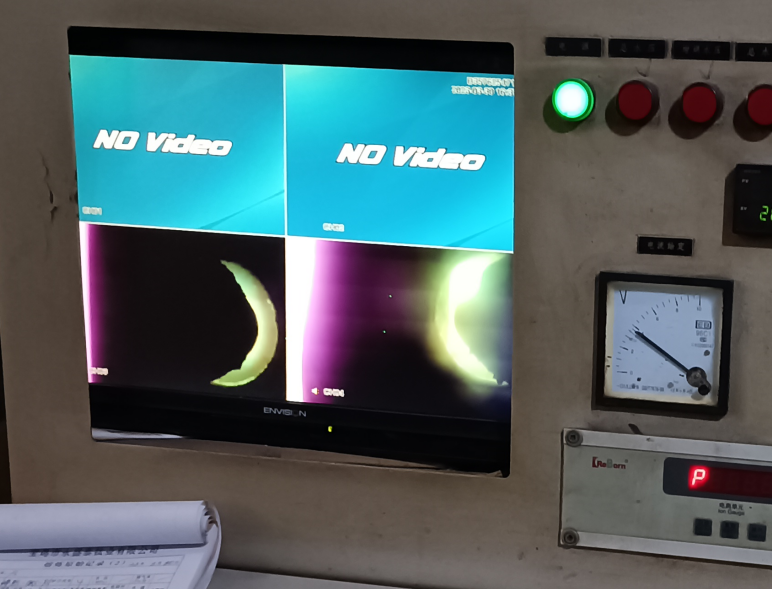

Therefore, titanium material smelting is currently the most commonly used: metal vacuum melting technology (VAR). You can only see the following:

Vacuum arc remelting is a kind of vacuum melting technology using arc as heat source to melt metal under vacuum conditions, referred to as VAR.

Let's start with a simple model: Light a candle, normally with the flame facing upwards. Titanium smelting, on the other hand, is the equivalent of holding a candle upside down with the flame facing down. Drops of wax fall inside the crucible and become titanium ingots.

The real principle of smelting titanium materials is that under slag free and vacuum conditions, the metal electrode rapidly melts under the high temperature action of the DC arc and is re-solidified in the water-cooled copper crystallizer.

The vacuum arc remelting process can be divided into four processes: welding electrode, arc initiation, normal melting and capping.

(1) Welding electrode. The consumable electrode used in each furnace must be coaxial with the transition electrode and solidly welded to the transition electrode. Welding is performed under vacuum. At the end of the consumable electrode is welded with a layer of the same kind of car dust as the arc starter, and then down the electrode rod, so that the transition electrode and the consumable electrode between the arc is heated and the arc is stable, when the two end faces of the arc are heated and the metal liquid phase is formed in the consumable extreme surface, the electrode rod is rapidly reduced, so that the two end faces of the arc are in close contact and welded together.

(2) Starting arc. An arc is formed between the consumable electrode and the arc starter at the bottom of the crystallizer, the temperature of the arc zone is raised, and a metal melt pool of a certain size is formed at the bottom of the crystallizer, and a stable arc is maintained between the consumable electrode and the metal melt pool, so that the remelting of the consumable electrode is transferred to normal melting.

(3) Melting period. It is the main period of the remelting process, during which the steel or alloy is refined and solidified into ingots, that is, the gas and metal impurities with low melting point are removed from the metal, the non-metallic inclusions are removed, the degree of segregation is reduced, and the ideal as-cast microstructure is obtained.

(4) Capping (also called feeding head). The aim is to reduce the shrinkage hole of the head of the remelted ingot, reduce the porosity of the "V" shaped shrinkage area of the head, promote the final floating and exclusion of inclusions, reduce the amount of cutting head and increase the yield.