What is a titanium anode? The full name of titanium anode is the metal oxide coated anode (MMO). Also known as KSA anode. (Dimensional shape stable anode). The titanium substrate is coated with precious metal coating to make it have good electrocatalytic activity and electrical conductivity.

Titanium anode classification: According to the anode precipitation gas in the electrochemical reaction to distinguish: the precipitation of chlorine gas called chlorine evolution anode, such as ruthenium-coated titanium electrode: the precipitation of oxidation is called oxygen evolution anode, such as ruthenium-coated electrode and platinum titanium mesh/plate.

Chlorine evolution anode (ruthenium-coated titanium electrode): high chloride ion content in the electrolyte: generally in the environment of hydrochloric acid and electrolytic seawater, electrolytic salt water environment. Such as ruthenium-iridium titanium anode, ruthenium-iridium tin titanium anode.

Oxygen evolution anode (iridium series coated titanium electrode): electrolyte is generally sulfuric acid environment. Corresponding to our company's products are iridium tin tin pole, high iridium anode.

Platinum-plated anode (platinum titanium mesh/platinum titanium plate): titanium as the substrate. The surface of the precious metal platinum, coating thickness is generally 1-5um (micron). Platinum mesh size is generally 12.7*4.5mm or 6*3.5mm.

Titanium anode manufacturing process:

Raw material preparation: The selection of high quality metal materials, such as industrial pure titanium or titanium alloy

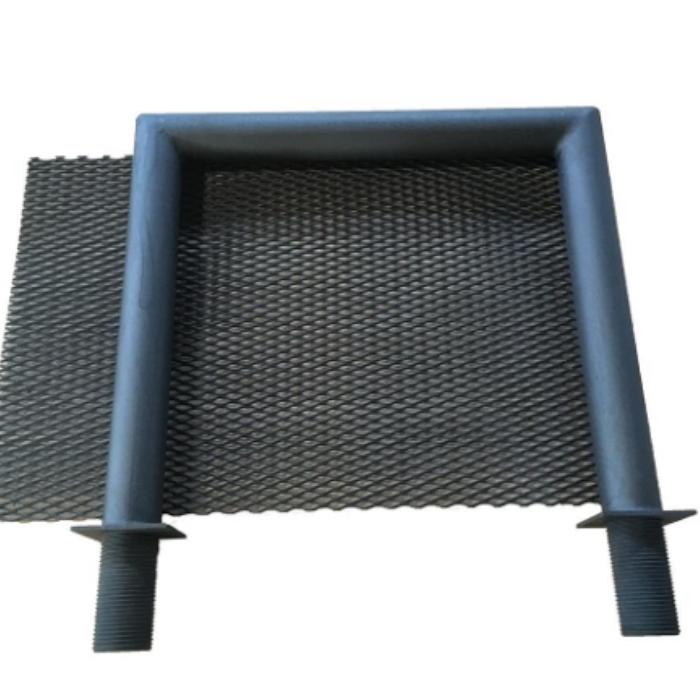

Substrate preparation: The titanium metal material is machined to make the substrate of the desired shape and size.

Surface treatment: Surface treatment of titanium substrate, such as chemical conversion, coating, etc., to improve its corrosion resistance and conductivity.

Processing molding: The processed substrate is cut, bent, drilled and other mechanical processing to make the final titanium anode.

Quality inspection: The quality of the finished titanium anode is tested to ensure that it meets the design requirements.

Advantages of titanium anode:

1. Trough low voltage, small energy consumption;

2. The rate of electrode loss is small and the size is stable;

3. The corrosion resistance of the electrode is good, the anode is less integrated into the liquid, keep the liquid clean, and make the performance of the coating more reliable;

4. Titanium anode adopts new materials and structure, which greatly reduces its weight and facilitates daily operation;

5. Long service life, and the matrix can be reused, saving costs;

6. The oxygen evolution overpotential is about 0.5V lower than that of the lead alloy insoluble anode, which reduces the tank voltage and energy consumption.

Titanium anode product application background:

As an electrode material, titanium is widely used in electroplating, electrolytic synthesis, electrochemical treatment of wastewater and fuel cells, etc., titanium electrode has strong corrosion resistance, high catalytic activity, high oxygen evolution potential, low hydrogen evolution potential, and is not only an excellent anode material, but also an excellent cathode material. In addition to a few mixed acids, titanium in hydrochloric acid, nitric acid, sulfuric acid, hydrofluoric acid, phosphoric acid and most electrolyte solutions, have shown excellent corrosion resistance. Many important electrochemical industry fields, such as hydrogen peroxide, ammonium persulfate, electrolytic water, etc., can be used as anode materials.