What are the characteristics of titanium alloy compared with other metals?

1. High specific strength, titanium alloy density of 4.5g/cm3 is only 60% of steel, often used in aircraft engine components, skeleton, skin and so on;

2. Good corrosion resistance, titanium alloy can work in wet weather and seawater media. But its corrosion resistance to reducing oxygen and chromium salt media is poor;

3. High thermal strength, the working temperature of titanium alloy can reach 500℃, aluminum alloy is only about 200℃;

4. High chemical activity;

5. Good low temperature performance;

6. Small thermal conductivity, small elastic modulus;

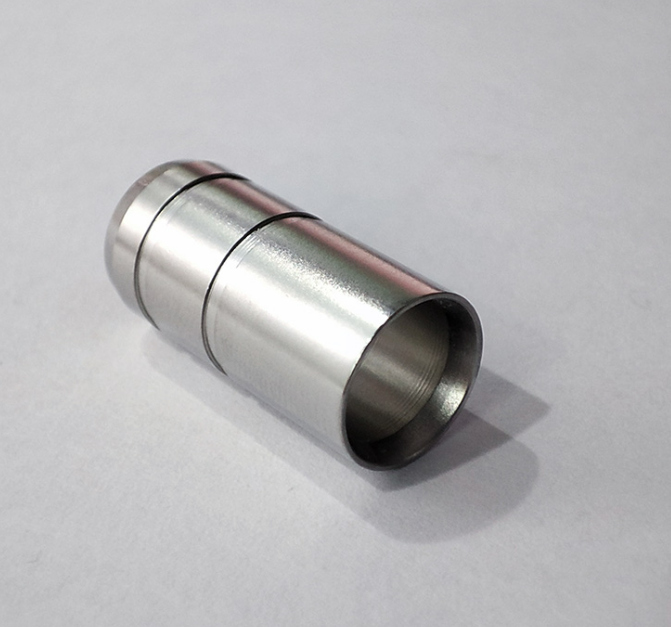

Titanium alloys are now the most attractive metal materials for biomedical applications. In medicine, they are used to implant devices to replace failing hard tissue. Examples include artificial hip joints, artificial knee joints, bone plates, fracture fixation screws, heart valve prostheses, pacemakers, and artificial hearts. So more and more titanium alloy precision processing.

When titanium alloy parts are processed, the processed material and the tool are easy to react with each other, forming melting, diffusion, resulting in sticking, burning, breaking and other phenomena.

Engineers and technicians summarized the machining characteristics of titanium alloy and CNC according to their experience:

1, the thermal conductivity is low, the heat is stored near the tool tip during cutting, causing the local temperature to rise fast, so the tool temperature is high, the tool tip is sharply worn, and the tool life is low.

2, due to the strong chemical activity of titanium alloy material, when the knife tip is high temperature, the thermal chemical reaction between the tool and the material is easy to oxygen, hydrogen and nitrogen, which increases the strength of the material and reduces the plasticity, resulting in significantly accelerated tool wear.

3, due to intermittent deformation of cutting, cutting resistance on the tip of the tool becomes dull, accelerate tool wear.

4, cutting fluid, cutting titanium alloy material, because the cutting temperature rises significantly, so in order to extend the service life of the tool must reduce the cutting temperature; Therefore, appropriate cutting fluid should be used in order to effectively reduce cutting resistance.

5, the elastic modulus is low, the elastic deformation is large, and the surface of the workpiece near the back knife surface is large, so the contact area between the machined surface and the back knife surface is large, and the wear is serious; These characteristics make it very difficult to process titanium alloy cutting, resulting in low processing efficiency and large tool consumption.

For the poor cutting performance of titanium alloy, how to choose the tool material?

Cutting of titanium alloy should be to reduce the cutting temperature and reduce the two sides of the binder, choose good red hardness, high bending strength, good thermal performance, and the titanium alloy parts processing cutting tool material with poor affinity, commonly used materials for cemented carbide YG8, YG3, YG6X, YG6A, 813643, etc.