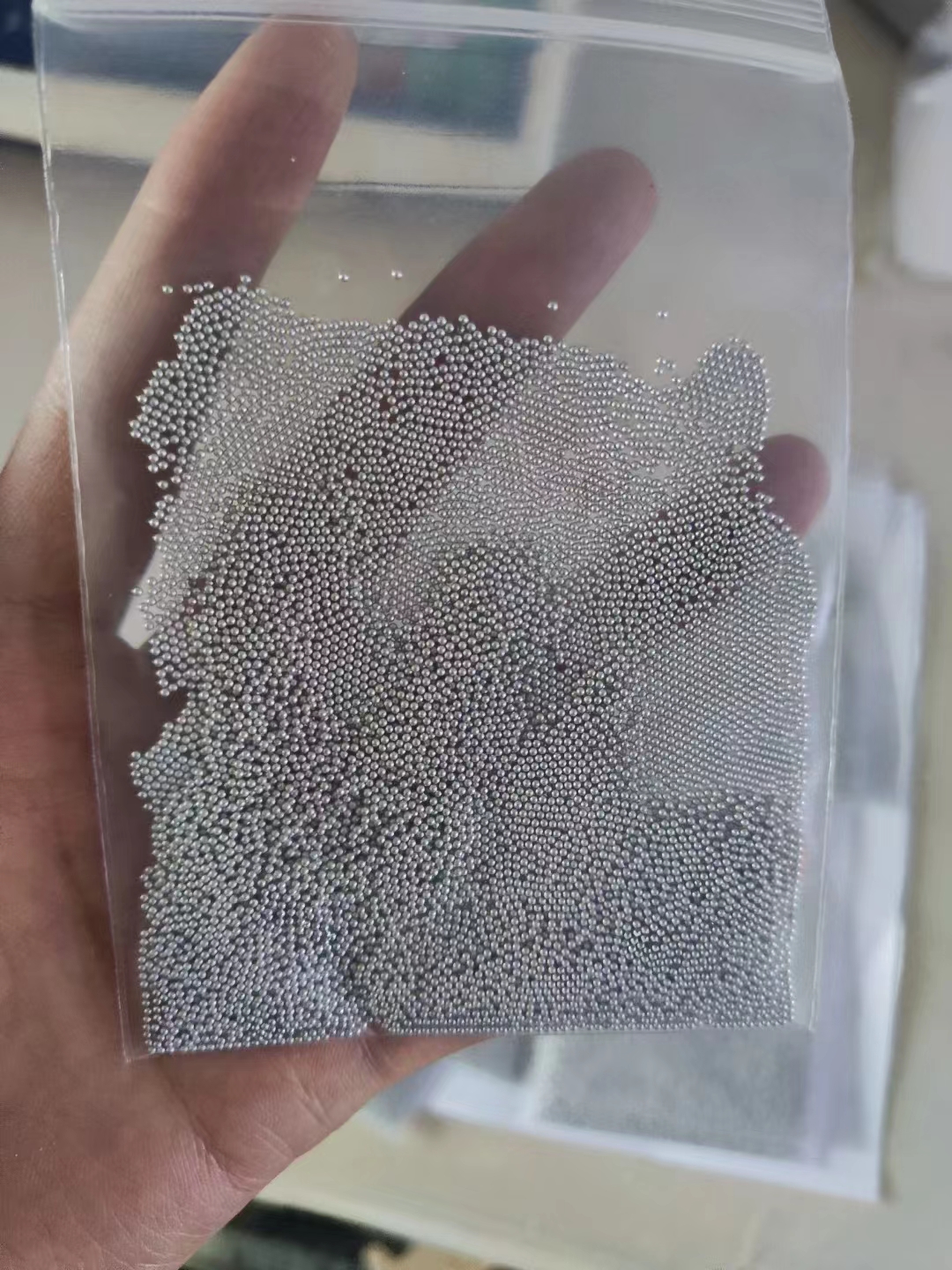

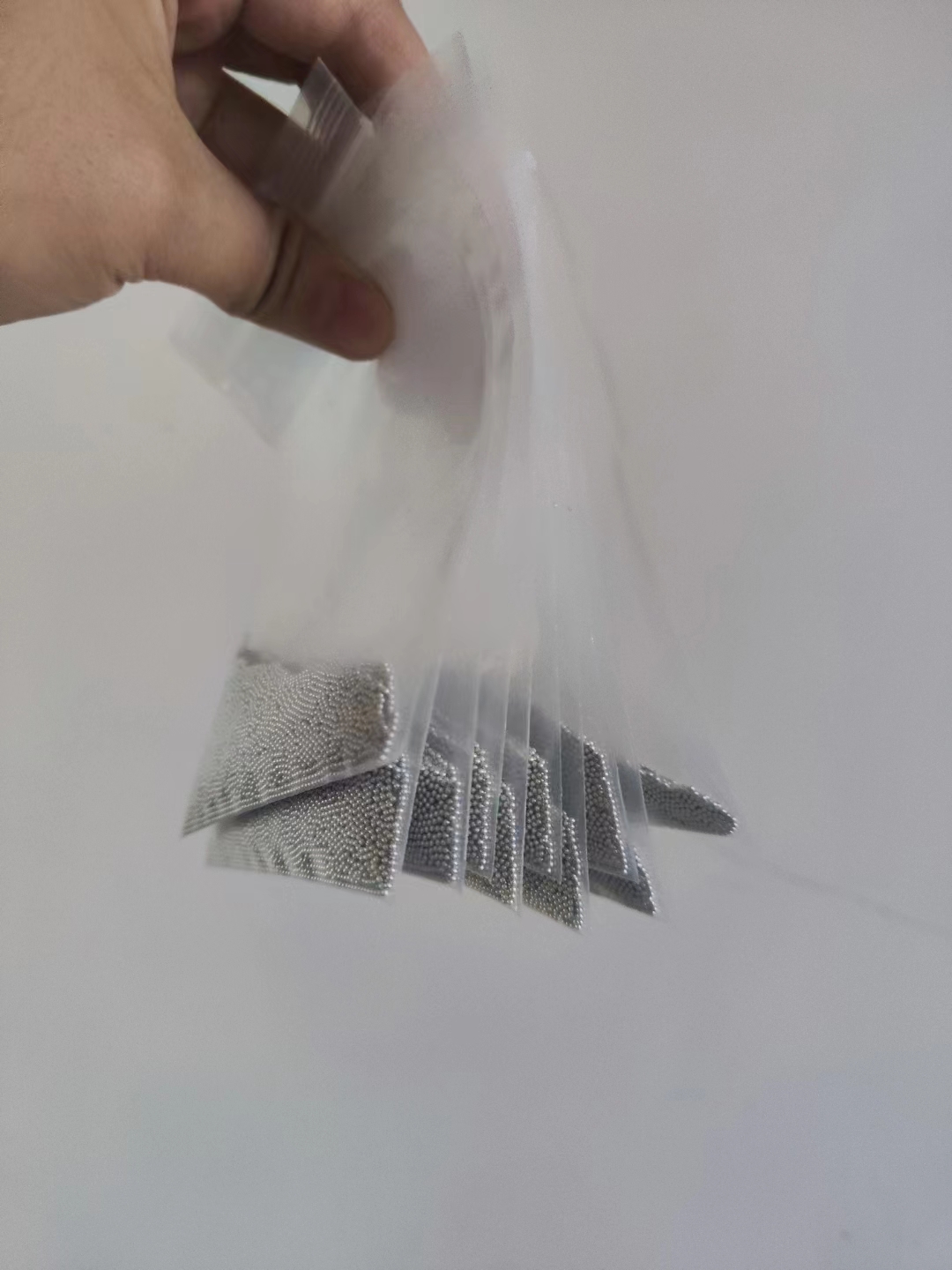

Titanium ball material: TA1(Gr1).TA2(Gr2).TC4(Gr5)

Titanium ball specification: diameter 1.0 ~ 200mm

Titanium ball implementation standards: GB/T3620-2007, GB/T3621-2007

Titanium ball processing technology:

1 Small titanium ball (φ1.0~ 10mm)

Cold heading - light ball - Heat treatment - surface strengthening treatment - hard grinding - preliminary research - flaw detection - finishing 1 - finishing 2

2 Small and medium-sized titanium balls (φ10 ~ 16mm)

Cold heading - light ball - Heat treatment - surface strengthening treatment - hard grinding - preliminary research - flaw detection - finishing 1 - finishing 2

3 Medium and large titanium ball (φ16 ~ 28mm)

Hot rolling-- annealing-- polishing ball-- heat treatment--surface strengthening treatment-- hard grinding--preliminary research--flaw detection- finishing 1-finishing 2

Titanium ball tolerance (+/-0.005mm), mirror, no trachoma, no cracks.

Titanium ball advantages:

Titanium balls can be passivated, and in an oxygen-containing environment, the passivated film can heal itself after being damaged. Resistant to corrosion, acid and alkali.

Titanium ball state: hot processing, cold processing, annealing

Titanium ball surface: all finished by mirror polishing.

Titanium ball applications: industrial, medical, cosmetics, jewelry, body piercing, bearing, aerospace, equipment