Three different forms of titanium alloy TA, TC, TB

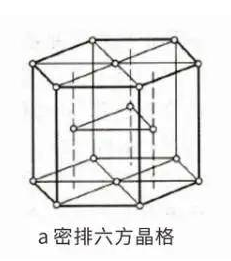

Titanium is an isomer with a melting point of 1668 ° C. At below 882℃, it has a close-packed hexagonal lattice structure, which is called alpha titanium;

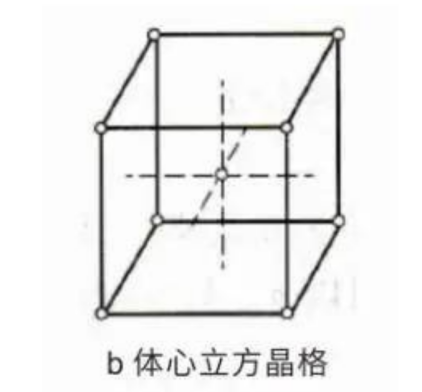

Above 882℃, it has a body-centered cubic lattice structure, called beta titanium.

The different characteristics of the above two structures of titanium, the addition of different intermediate alloying elements (aluminum, vanadium, molybdenum, etc.), so that the phase transition temperature and phase fraction content of titanium alloys with different structures are gradually changed.

At room temperature, titanium alloys have three matrix structures, and titanium alloys are divided into the following three categories: α alloy, (α+β) alloy and β alloy. In China, they are represented by TA, TC and TB.

Alpha titanium alloy

The single-phase alloy composed of α-phase solid solution is α-phase at general temperature or at high practical application temperature, and the structure is stable. At the temperature of 500℃ ~ 600℃, it still maintains its strength and creep resistance, but it can not be strengthened by heat treatment, and the strength at room temperature is not high.

Beta titanium alloy

The single-phase alloy composed of β solid solution has high strength without heat treatment, and the alloy is further strengthened after quenching and aging. But the thermal stability is poor, should not be used at high temperatures.

Alpha + beta titanium alloy

Biphase alloy, has good mechanical properties, good structure stability, good toughness, plasticity and high temperature deformation properties, can be better hot pressure processing, can be quenched, aging to strengthen the alloy. The strength after heat treatment is about 50% ~ 100% higher than the annealing state; High temperature strength,

The most commonly used of the three titanium alloys are α titanium alloy and α+β titanium alloy; The cutting workpiece of α titanium alloy is the best, followed by α+β titanium alloy, and β titanium alloy is the worst (basically rarely used this).

At present, the titanium alloy commonly used in the world is TC4 (Gr5) Ti-6Al-4V. The brand process is mature, and all products are basically developed around this basis.

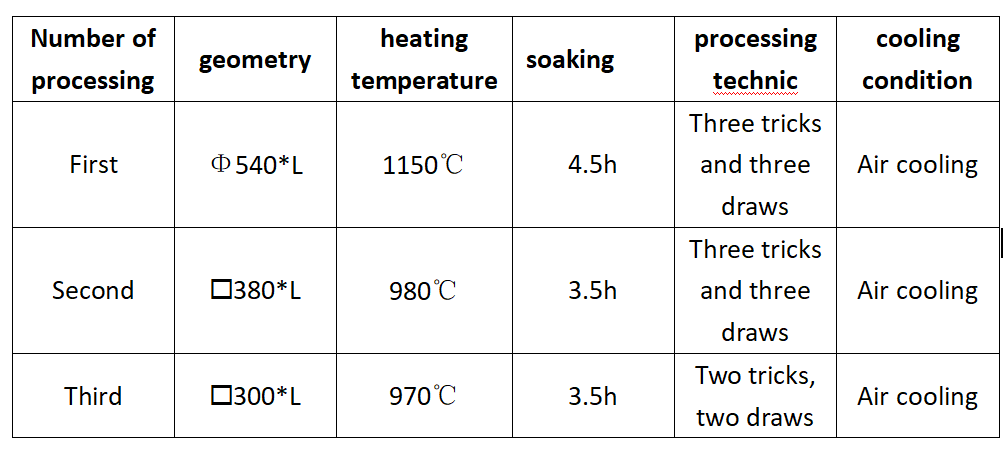

Baoji Yumingda Metal Materials Co., Ltd. is processed according to the following process:

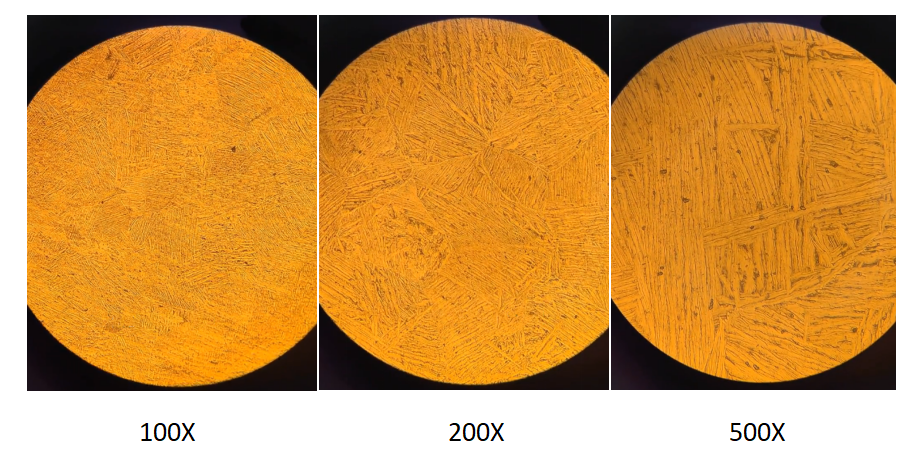

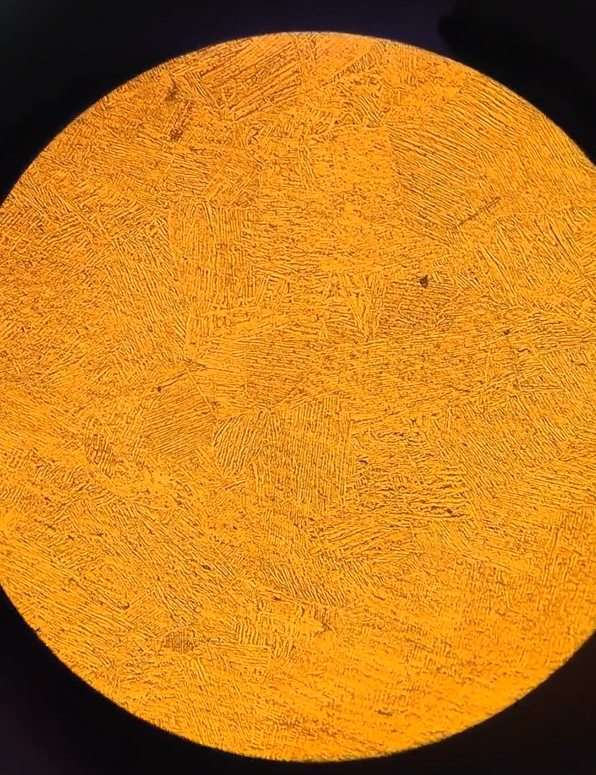

Sampling location: core