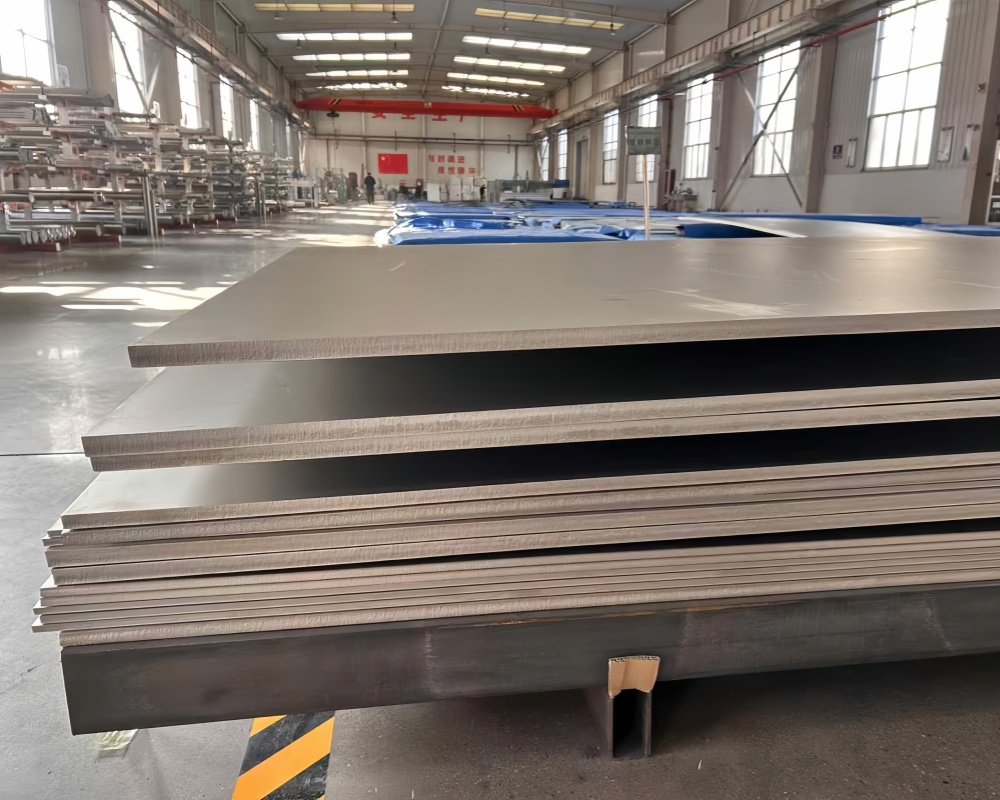

In the manufacturing industry of titanium and titanium alloys, laser cutting, shearing machine, and water jet cutting are three mainstream cutting technologies. Each of them has its unique physical principles, capability boundaries, and applicable scenarios. Choosing which technology to use is definitely not a simple decision, but a comprehensive decision-making process based on material characteristics, processing requirements, production costs, and return on investment. Before selecting different processes, it is essential to first understand the distinct processing essences of the three technologies.

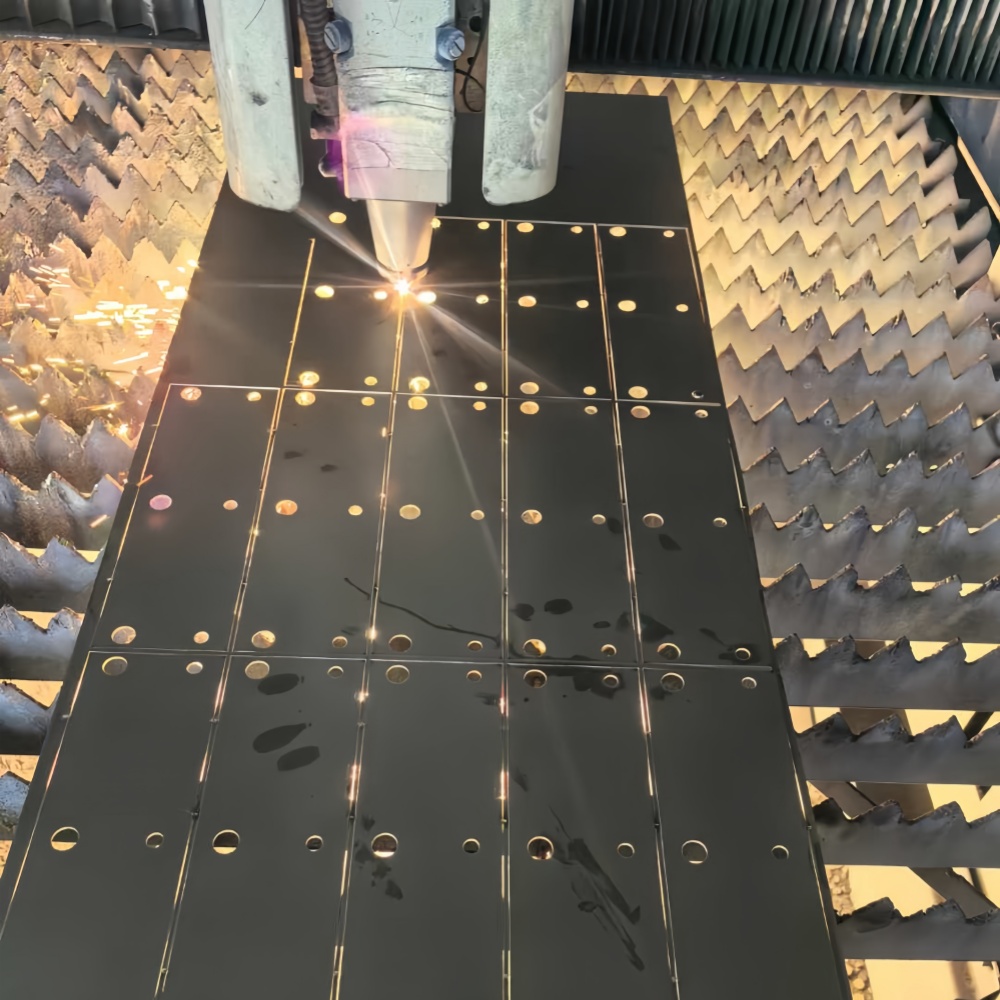

Laser cutting utilizes a high-power density laser beam, formed after being focused by a lens, as a heat source to irradiate the workpiece, causing it to rapidly reach its melting point or boiling point. Simultaneously, high-speed auxiliary gas (such as argon or nitrogen) coaxial with the beam is used to blow away the melted or vaporized material, thereby forming a cutting slit.

Laser cutting is a thermal cutting process, where the product is heated, resulting in significant thermal deformation. The cutting seam is extremely narrow, with a smooth cross-section and good verticality. The precision can reach the order of ±0.1mm, allowing for the cutting of complex contours. The cutting speed is extremely fast for thin titanium plates (such as those below 6mm). However, as the thickness increases, the speed significantly decreases, and the piercing time becomes longer. The cutting process produces intense arc light and harmful gases, often requiring enclosed workbenches and powerful dust removal systems.

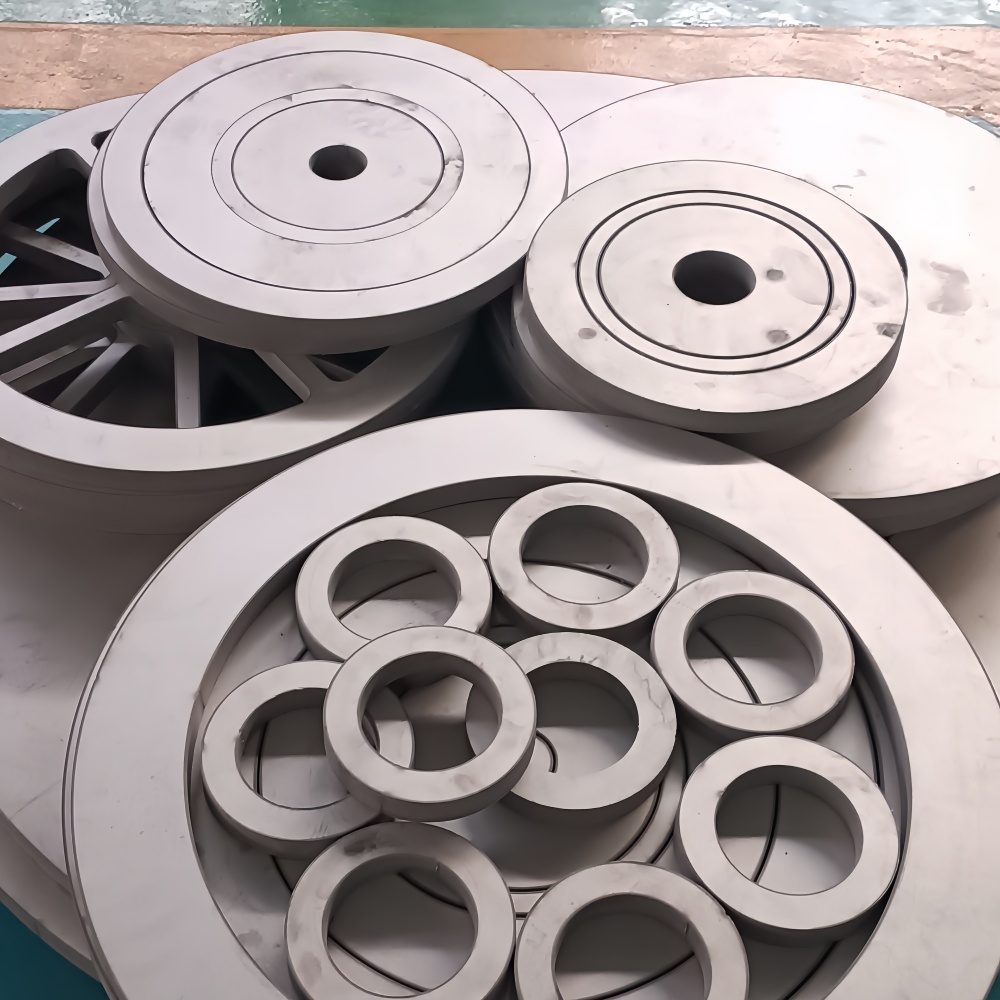

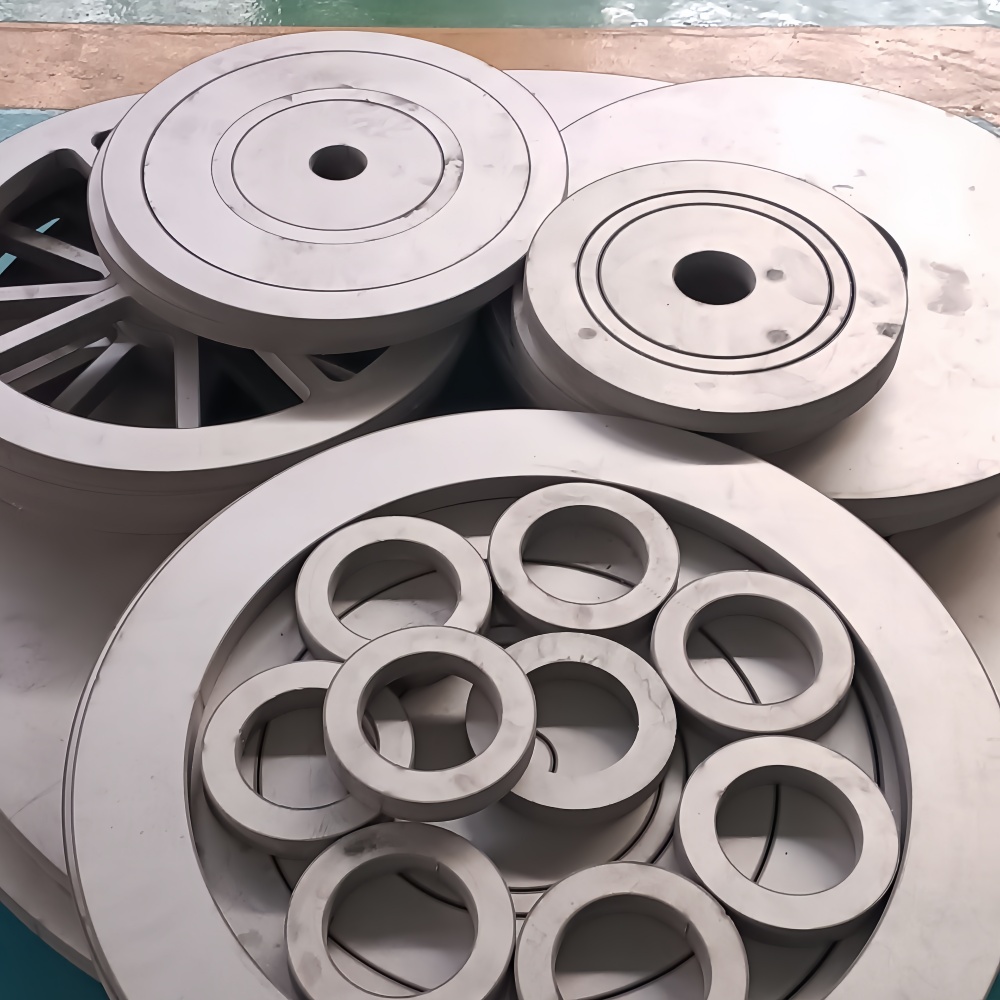

Water jet cutting, commonly known as water cutting, is a completely different "cold" processing technology. Its principle is to pressurize ordinary water to ultra-high pressure above 200 MPa (approximately 2000 atmospheres), and eject it through an extremely fine gemstone nozzle (with a diameter of about 0.3 mm) to form a "water jet" with a speed up to several times the speed of sound.

Water cutting is a cold process, where the product is barely heated and shows no significant deformation. The cut surface is smooth with a clear inclination (larger at the top and smaller at the bottom), achieving a precision of up to ±1mm, and capable of cutting complex graphic contours. When cutting thick titanium plates (such as those over 6mm), the cutting speed is slow, especially when cutting ultra-thick titanium plates. The equipment investment is second-highest, and the operating costs involve water, electricity, abrasives, and maintenance, making the cost per unit length potentially the highest. Water cutting does not produce toxic gases or smoke. However, it does generate noise, primarily from the high-pressure pump.

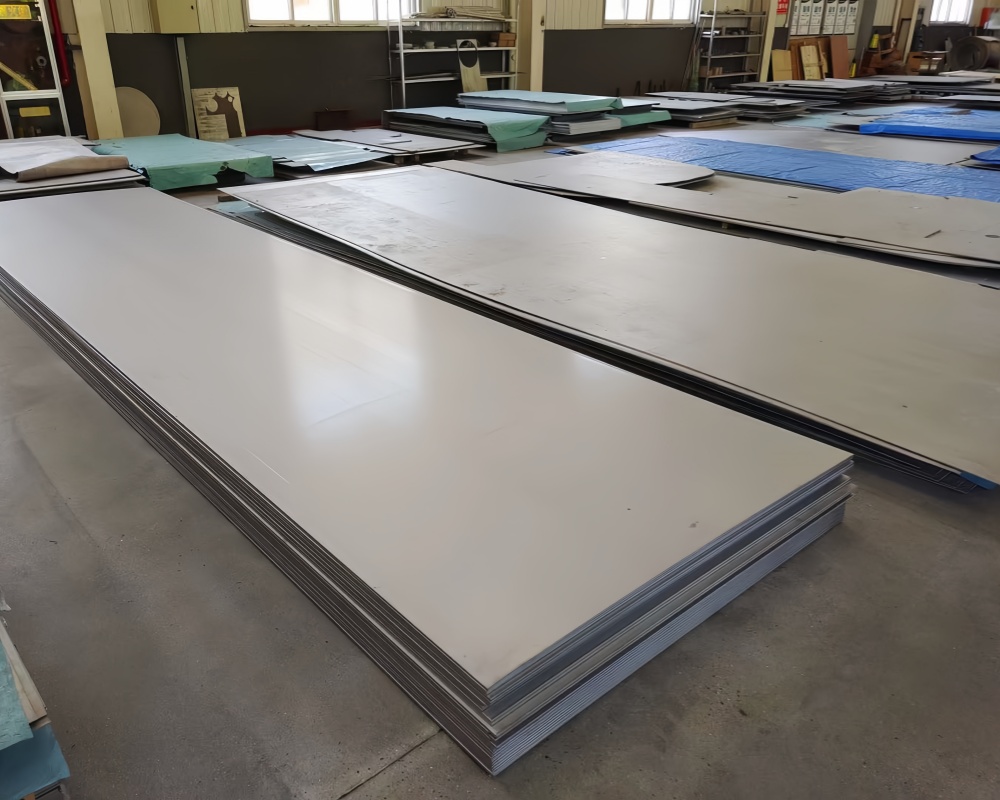

Shearing with a plate shearing machine is a relatively traditional cold processing technique. Its principle is similar to that of scissors used at home, where the scissors are enlarged and divided into upper and lower parts, and an oil pressure system is used in conjunction. It is a machine that uses one blade to make reciprocal linear motion against another blade to shear titanium plates. With the moving upper blade and the fixed lower blade, and by adopting a reasonable blade gap, it applies shear force to metal titanium plates of various thicknesses, causing the titanium plates to fracture and separate according to the required size.

The plate shearing machine can only cut regular titanium plates and cannot be used for processing irregular shapes. It can shear titanium plate materials of various thicknesses. Commonly used plate shearing machines are divided into three types: flat shearing, rolling shearing, and vibrating shearing. The flat shearing machine is the most widely used. Plate shearing machines with a shearing thickness of less than 10mm are mostly mechanically driven, while those with a thickness greater than 10mm are hydraulically driven. Generally, metal shearing is performed by foot pedal or button operation for single or continuous shearing. It is not safe for one person to operate the plate shearing machine alone. It should be coordinated by 2-3 people for feeding, controlling dimensional accuracy, and material retrieval, with one person providing unified command.

With the rapid development of titanium and titanium alloy processing technology, and the increasing adoption of "flexible manufacturing" models, titanium plate cutting processes are now equipped with complementary technologies such as lasers, water jet cutting, and shearing machines, enabling the solution and improvement of titanium plate cutting issues.