These past few months have been quite busy, with a lot of work involved in receiving clients and conducting third-party factory inspections. After a period of over half a year of product verification and development, an European client finally included our titanium processing parts in their list of qualified suppliers and is about to start mass production. They will conduct an audit or assessment of our factory according to the standards set by the client; this generally includes human rights factory inspections (social responsibility factory inspections), quality factory inspections (technical inspections or production capacity evaluations), etc.

In the early stage of the product development, the customers sent us samples for testing in their country's laboratories. It took nearly a month before the samples passed the tests. We provided the customers with various certifications such as ROHS, MSDS, ISO9001, ISO45001, ISO14001, etc. as per their requirements. Our investment in this project was huge. After the samples passed the tests and the certifications in the customer's country laboratory, the customer said that they needed to have a third-party inspection conducted there. The customer entrusted TUV Company to conduct the third-party inspection.

Two engineers from TUV Company contacted us as per the requirements. Both of them are familiar with Chinese and have been coming to China for inspection on a regular basis. They have a basic understanding of Chinese and their Chinese names are: Ouyang and Sam (one male, one female). They surprised us by using WeChat. We wrote the pick-up notice in Chinese, then communicated about their eating habits and arranged their hotel accommodation for the next three days.

On the first day, at 08:30, the first meeting was held (including the production department, the purchasing department, the quality department, the technical department, the business department, the human resources department, and the management level). The purpose and gratitude of cooperating with the factory inspection were explained. Their factory inspection mainly follows the ISO standards, mainly focusing on reviewing documents. Therefore, it is necessary to ensure that the document materials prepared according to the previous inspection materials are complete (especially the quality inspection department). The time for the factory inspection should be arranged according to the inspection plan provided by the inspectors. An independent and spacious office should be prepared for them to use. At the same time, attention should be paid to the environmental hygiene of the factory (including bathrooms, production lines, etc.). For ISO9001 or ISO14001, most of them require reviewing some factory management documents from the past three years, including QC inspection records, production records, warehouse records, machine maintenance records, etc. The most difficult part is that all the records within these past few years need to be kept completely.

On the second day of the actual factory inspection, the inspection was carried out by department and the materials of each department were inspected. Then, starting from that point, the materials were inspected by each department and conversations were held with the managers of each department. After each conversation, we would communicate with their colleagues in the company via video or voice calls, using English. During this process, we were present throughout. Sometimes, we needed to ask the managers of each department questions or some material documents (including printing and photocopying materials at any time, etc.).

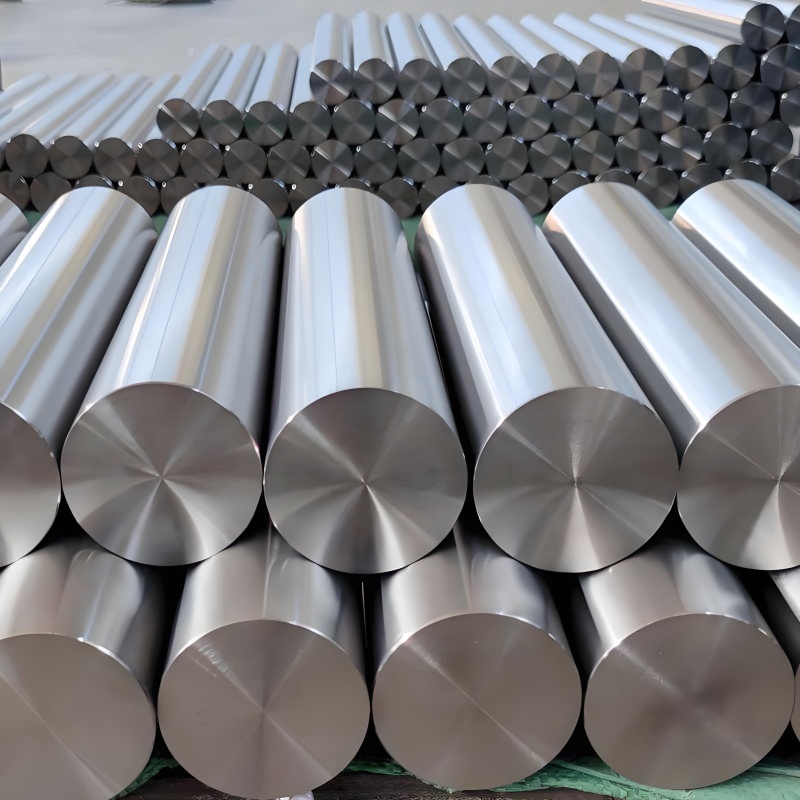

The main task was to take photos and record every step of the processes of our production department (warehousing) and quality inspection department (each department needs to accompany and inspect the site, and we also need to keep records on the spot. These records are to facilitate understanding the problems that arise and the areas that need to be rectified in the future). This includes everything from the storage of raw material sponge titanium, inspection records, electrode block pressing records, titanium ingot ratio table, intermediate alloy metering table, vacuum melting records, titanium ingot melting records, titanium ingot stripping records, chemical composition records, titanium alloy forging records, temperature records, and electric furnace verification records... every production process and process parameter of the products were photographed and recorded. We almost dug our factory to its core. Each department and each person involved was extremely cautious and cautious, as if walking on thin ice. The inspection on the site the next day was the most exhausting. Fortunately, we all passed the inspection and basically achieved "do what I wrote, write what I did".

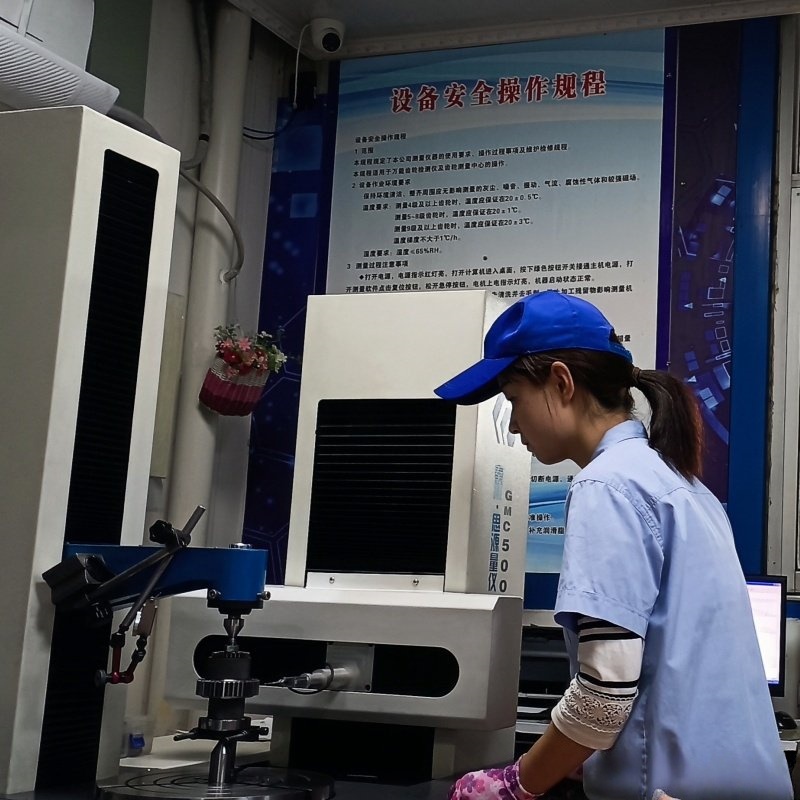

For the quality inspection department, the key checks were conducted on aspects such as inspection standard documents, maintenance and warranty records of experimental instruments, product sampling inspections, measurement tool and equipment ledgers, and annual customer complaint records. The QC personnel conducted on-site questioning of problems and verified the qualifications of key QC positions. A GR&R test was also carried out on-site. Key measurement personnel were arranged on-site to measure samples and collect data. The procurement department, technical department, human resources department, and management leaders of the company were respectively consulted and questioned regarding the company's relevant departmental documents.

The final meeting on the third day. Further improvements and rectifications will be carried out. The existing problems will be described and confirmed with the leaders of each department. At the same time, several copies of rectification forms with the signatures of the department heads will be printed for subsequent rectification filling. The time required for rectification to provide a solution is approximately one week. Written materials and pictures need to be submitted. The rectification period lasts for one month. After one month of rectification, it needs to be inspected and certified by the TUV company's certification institution. If the review is qualified after one month, then only a one-year annual review will be arranged after another 12 months. After all, this is not simple - it ends with just one factory inspection. It is a long-term continuous cooperation and supervision.

Through this factory inspection, the following points must be achieved and exist in every aspect of our work.

First, the factory itself must attach importance to it. No matter what you do, without an active and serious attitude is not acceptable. Especially preparing for the factory inspection is a complex, cumbersome task that requires caution and cannot have any mistakes.

Second, if you don't pay attention to details in daily life, when the time comes, you will be in a rush and forgetful, causing unnecessary troubles.

Third, do it on a daily basis and involve all staff.

Fourth, review all documents, have a clear logic, be familiar with the materials, and go through them all. Don't wait until the day of the audit when the auditor asks for a certain document and you can't find it, or another document and you can't find that one. Then you will be in a panic.

Fifth, doing your own job well is the fundamental principle.