Compared to the common perception of titanium, professionals in the titanium industry would say, 'Titanium and titanium alloys'. Today we will mainly discuss the most commonly used Gr5/TC4 in titanium alloys. How can qualified titanium products be manufactured? We have to mention forging.

Every titanium product cannot do without forging. It is impossible to manufacture a perfect titanium product without going through a thousand trials and tribulations. Titanium forging is not simply about "forging iron", but a key process that improves the internal structure of titanium alloys through precise control of temperature and pressure. The forged titanium alloy will have finer and more uniform internal grains, and its mechanical properties can be improved by more than 30%.

TC4 alloy (Ti6A14V) is the most widely used titanium alloy grade both domestically and internationally, with excellent comprehensive properties and a phase transition point of 980-1010 ℃. It can be processed and prepared into various varieties such as plates, rods, rings, wires, and forgings. The coexistence of alpha and beta phases in titanium alloys ensures both material strength and good shaping. How to obtain excellent equiaxed structure of titanium TC4 alloy (Ti6A14V)?

How to manufacture a perfect titanium alloy forging? There must be three major treasures.

1. Temperature control requires both high-temperature and low-temperature furnaces. Titanium alloy is most obedient at 900-950 ℃, where it maintains sufficient strength and good plasticity.

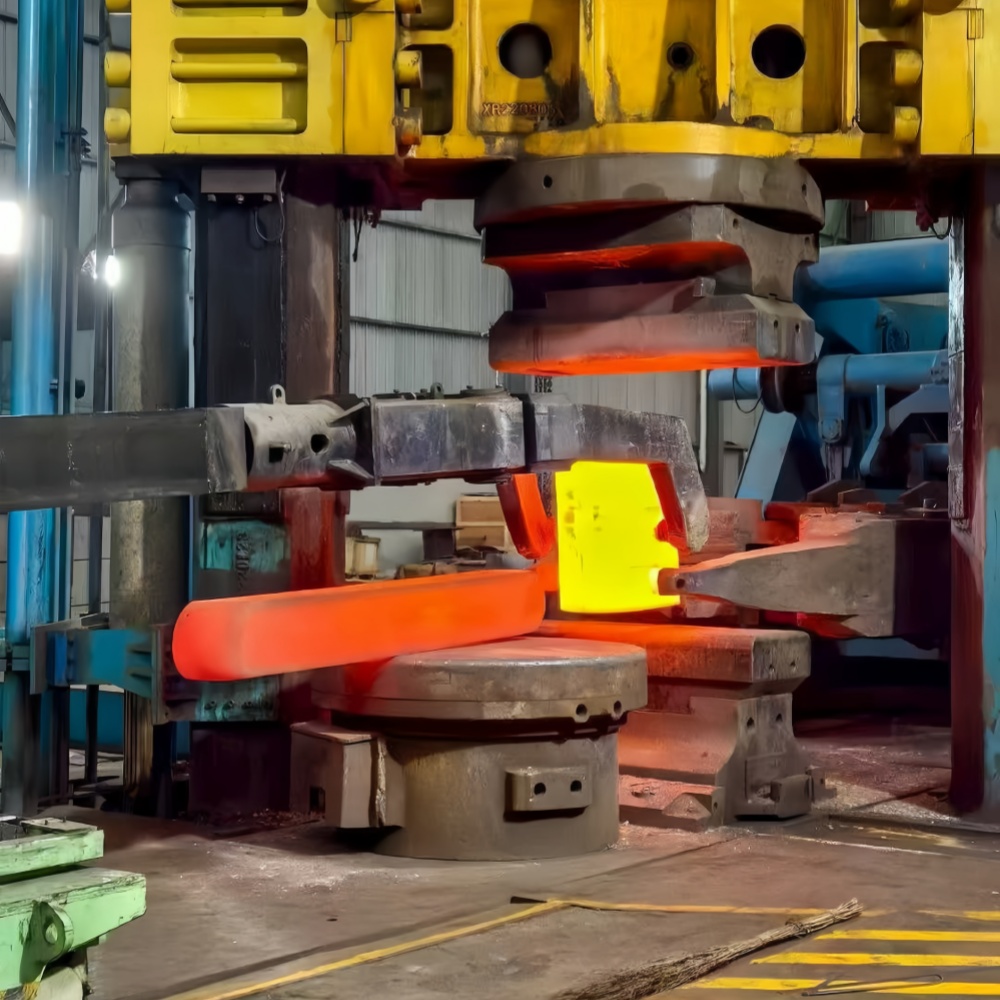

2 Large tonnage forging machines: Large tonnage hydraulic forging machines, capable of generating force equivalent to the pressure of 1000 elephants simultaneously stepping on a coin.

3 professional forging teams: A closely coordinated professional operation team requires at least 8 people, long-term cooperation, mutual cooperation, and tacit operation.

The forging process is generally divided into three stages.

1. Preheating of cutting materials; Cut the titanium alloy billet into appropriate sizes and slowly heat it up to the forging temperature (1150 ℃) in a preheating furnace.

2 Forging: Initial shaping is carried out on a press machine, and the metal can be kneaded like dough, usually in the form of three pillars and three bars, crushing large grains of titanium ingots. According to different product requirements, one fire forging, two fire forging, three forging, etc. can be used.

3 Heat treatment: Through insulation and slow cooling at a specific temperature, internal stress is eliminated and material properties are stabilized. Different products correspond to different heat treatment temperature regimes.

Requirements for forged titanium alloy forgings: smooth surface, no defects such as cracks or folds. The size meets the design requirements. Through advanced testing methods such as ultrasonic testing, we ensure that every product meets the standards required by our customers.

Forging titanium and titanium alloys is a science. Through the close combination of materials, heat, and strength. By precisely controlling parameters, titanium and titanium alloys can be transformed into high-precision and cutting-edge products. Let titanium and titanium alloy products enter our lives.