We all know that titanium and titanium alloys have strong corrosion resistance, especially in acidic, alkaline and chlorinated environments, and are widely used in the chemical industry, marine engineering and other fields. Titanium flanges, titanium valves and titanium reducers are common products in titanium enterprises.

Today, we will not discuss how they are produced, but mainly focus on the interpretation of customer product requirements. There are various standards in the chemical industry, but most of them are based on ASME B16.9-2012 "Forged Steel Butt-Welding Fittings for Pipe" and ASTM B363 "Requirements for Seamless and Welded Titanium and Titanium Alloy Pipe".

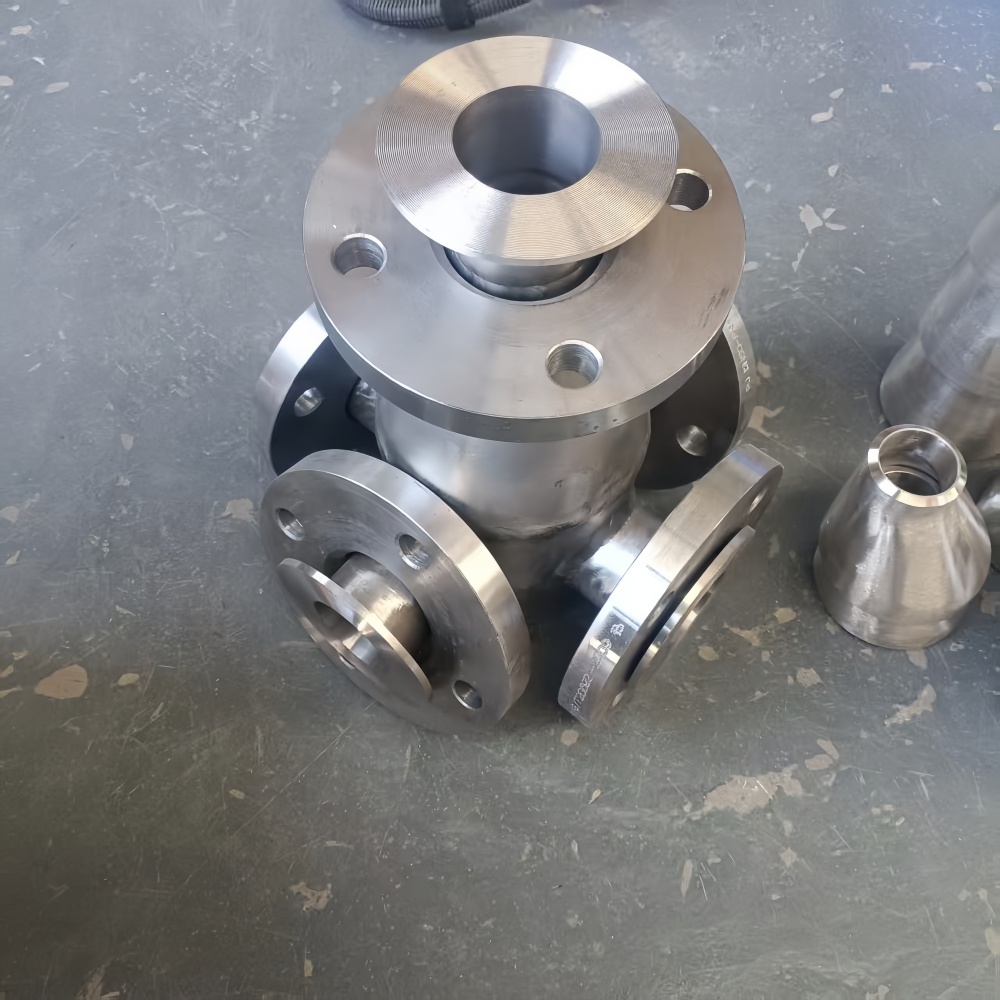

Titanium flanges are parts made of titanium and titanium alloys that connect pipes to each other and are connected to the pipe ends. Titanium flanges have holes, and bolts are used to tightly connect the two flanges. A gasket is used to seal the flange. Generally speaking, the diameter of the pipe can be divided into outer diameter (De), inner diameter (D), and nominal diameter (DN). DN refers to the nominal diameter of the pipe: it is neither the outer diameter nor the inner diameter; it should be related to the early development of pipeline engineering and the imperial system. Its corresponding relationship with the imperial system is as follows:

4分管:4/8 inches: DN15;

6分管:6/8 inches: DN20;

1寸管:1 inch: DN25;

1又1/4寸管:1 1/4 inches: DN32;

1又1/2寸管:1 1/2 inches: DN40;

2寸管:2 inches: DN50;

3寸管:3 inches: DN80 (many places also mark it as DN75);

4寸管:4 inches: DN100.

Titanium reducers are metal pipes made of titanium and titanium alloys with high corrosion resistance. Their important role is that they can be used in special occasions such as the chemical industry. In traditional metal pipes, they are prone to rupture due to corrosion, while the superior properties of titanium reducers can avoid this situation. When receiving customer orders, how to convert the specifications into understandable technical language. It is necessary to analyze each standard one by one. Example 1:

DN80MM, S-10S, 45 Deg, L/R, BW, ASTM B363, WPT2.

Standard and material: ASTM B363 is the manufacturing standard for titanium and titanium alloy pipe fittings, and WPT2 represents the material grade of titanium alloy Gr2 (Grade 2).

Specification parameters: 80MM: nominal diameter about 3 inches (DN80).

S/10S: wall thickness grade is Sch 10S (thin wall series), suitable for low-pressure or corrosive medium pipeline systems.

45 Deg: elbow angle is 45 degrees, usually used to change the direction of the pipeline and reduce pressure drop.

L/R: long radius (Long Radius), the bending radius is 1.5 times the pipe diameter, with less fluid resistance.

BW: refers to Butt Weld (butt weld), which mainly indicates that the connection method of this elbow is completed by butt welding.

Example 2: 50MM S/10S Equal Tee ASTM B363 WPT2H, BW, WP-S. Material and standard:

ASTM B363: standard for manufacturing seamless or welded titanium and titanium alloy pipe fittings, covering types such as equal tees (Equal Tee).

WPT2H: material grade is titanium alloy Gr2 (Grade 2).

Specification analysis: 50MM: nominal diameter is DN50 (NPS 2 inches).

S/10S: wall thickness grade is Sch10S, corresponding to nominal wall thickness 2.8mm (applicable to DN50 pipe diameter).

Equal Tee: The three-way is of equal diameter structure (the inlet and outlet diameters are the same), meeting the dimensional requirements of the ASME B16.9 standard.

BW (Butt Weld): Butt-weld connection form, which requires matching the pipe end bevel processing and then welding.

WP-S: It may indicate that the surface treatment is pickling or sandblasting to ensure the cleanliness and corrosion resistance of the welding area.

From the complex pipe racks in large chemical plants to deep-sea oil and gas pipelines, titanium flanges and titanium reducers play an indispensable role in industry. For us engineering technicians, only by deeply understanding their technical characteristics and selection logic can titanium flanges and titanium reducers precisely play an increasingly important role in the pipeline system.