Titanium plates are widely used in multiple fields due to their excellent mechanical properties, corrosion resistance and low density. Titanium plates in aerospace, chemical equipment, medical devices, Marine engineering and other fields have broad application prospects. Their unique properties make them play an irreplaceable role in multiple industries. The oxide film on the surface of titanium plates is equivalent to a good long-lasting and wear-resistant separation agent. The use of titanium seed plates saves the separation agent, makes the plate stripping easy, and eliminates the pre-treatment process of the seed plates. Therefore, the application of titanium plates is more extensive.

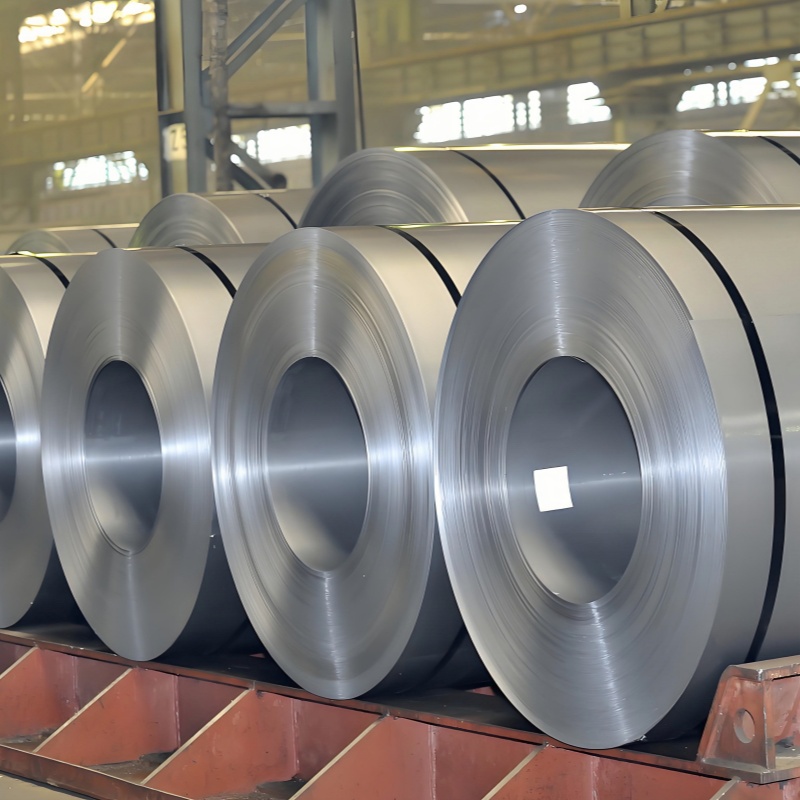

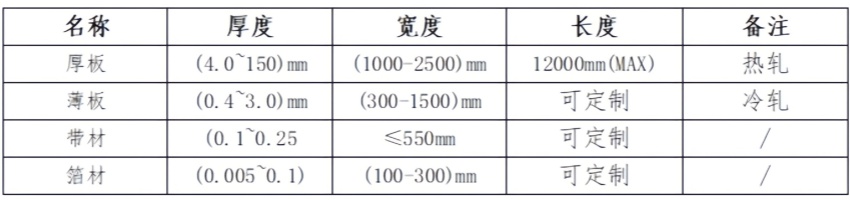

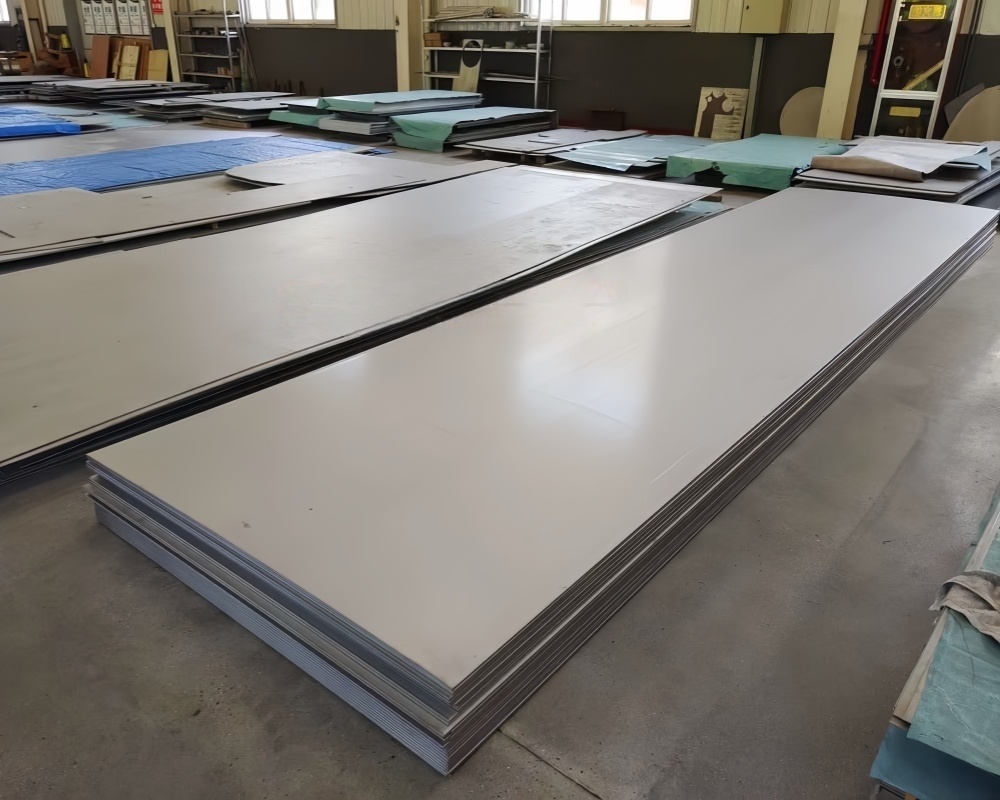

How to produce a suitable titanium plate is what we are going to cover today. Firstly, "titanium plate" is a general term. Titanium plates include hot-rolled plates, cold-rolled plates, titanium coils, titanium strips, titanium foils, etc. Today we mainly discuss titanium hot-rolled plates.

The process of hot-rolled titanium plates is mainly divided into: slab making and titanium plate rolling.

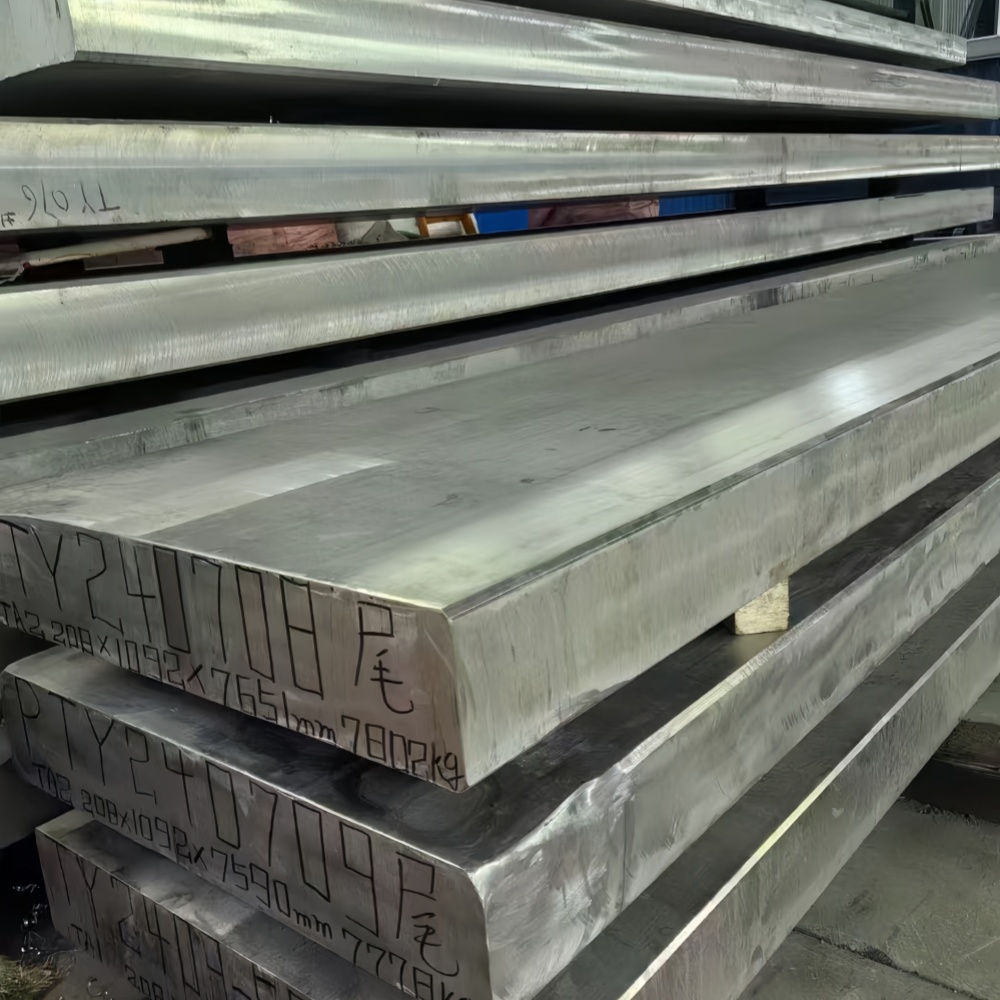

Slab production: Titanium plates, like other titanium products, originated from titanium ingots initially. But the only difference is the giant titanium ingots, weighing more than 6 to 10 tons. Titanium ingots need to be forged to obtain titanium billets of 210*1100*8000mm. The black skin oxide layer on the surface of the billet is removed (generally, a large gantry milling machine is used to mill off the oxide scale on all four sides of the slab).

First of all, we need to know what hot rolling is: it refers to the rolling process carried out above the recrystallization temperature of titanium billets. Now let's imagine a scene in our minds: the common noodle machine in northern households, and think of the titanium plate as noodles. Carry out multi-pass pressing and rolling. The basic principle of actually producing titanium plates is the same as this one, but it is more complex and precise.

Titanium plate rolling mainly consists of four major processes: heating, rough rolling, finish rolling, cooling, and surface treatment

Heating: Place the titanium plate blank at a sufficiently high temperature, simply put, an appropriate temperature. The suitable temperature for titanium plates is between 900℃ and 1000℃. When the time is long enough, the general heating and holding time is more than 4 to 4.5 hours.

Rough rolling: After heating, the titanium billet is descaled by high-pressure water to remove the surface oxide scale, and then enters the rough rolling mill for initial forming. Rough rolling usually adopts reversible rolling methods (such as two-roll or four-roll mills), and the billet is rolled to an intermediate thickness through multiple passes. This stage may also include widening rolling or shaping rolling to adjust the width and shape.

Finishing rolling: After the intermediate billets undergo head and tail cutting treatment, they enter the multi-stand finishing mill group (such as 7 four-stand rolling mills). Finishing rolling reduces the material to the final thickness through high-speed rolling and precise reduction control, and adopts plate shape closed-loop control technology to ensure dimensional accuracy.

Cooling and coiling: After fine rolling, the titanium coils are rapidly cooled to the coiling temperature through a laminar flow cooling system and then coiled by a coiling machine. The cooling needs to be dynamically adjusted according to different grades of titanium materials and the final rolling temperature to optimize the material properties. The final product may still need further processing such as bundling and marking.

Characteristics of hot rolling:

It features low energy consumption, good plastic processing, low deformation resistance, insignificant work hardening, easy rolling, and reduces the energy consumption required for metal deformation.

2. Hot rolling usually adopts large ingots and large reduction rolling, with a fast production pace and high output, which creates conditions for large-scale production.

3. The as-cast structure is transformed into a processed structure through hot rolling, and the plasticity of the material is significantly enhanced through this transformation of the structure.

4. The characteristics of the rolling method determine that the properties of the rolled sheet are anisotropic. Firstly, there are obvious performance differences in the longitudinal, transverse and high directions of the material. Secondly, there are deformation textures and recrystallization textures, and there is a clear directionality in the punching performance.

The hot rolling process of titanium plates, as a core technology in the processing of high-end metal materials, has its core advantages reflected in the refinement of titanium alloy microstructure and performance optimization through precise temperature control (850-950℃) and multi-pass rolling. The current technology has broken through the industry bottlenecks such as the traditional rolling force fluctuation of ±5% and the plate shape tolerance of ±0.1mm. However, in the face of the demand for higher strength-to-toughness ratios of alloys like TA15 and TC4 in the aerospace field, continuous innovation is still needed.