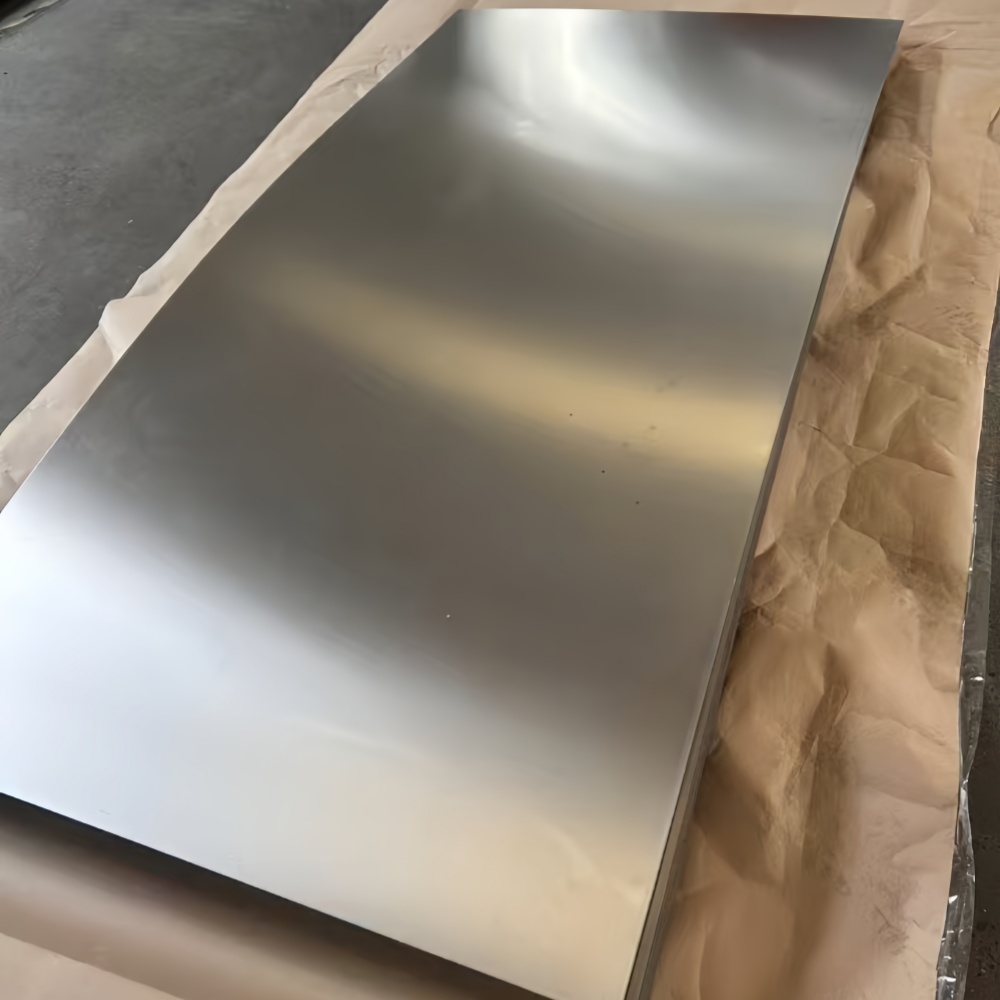

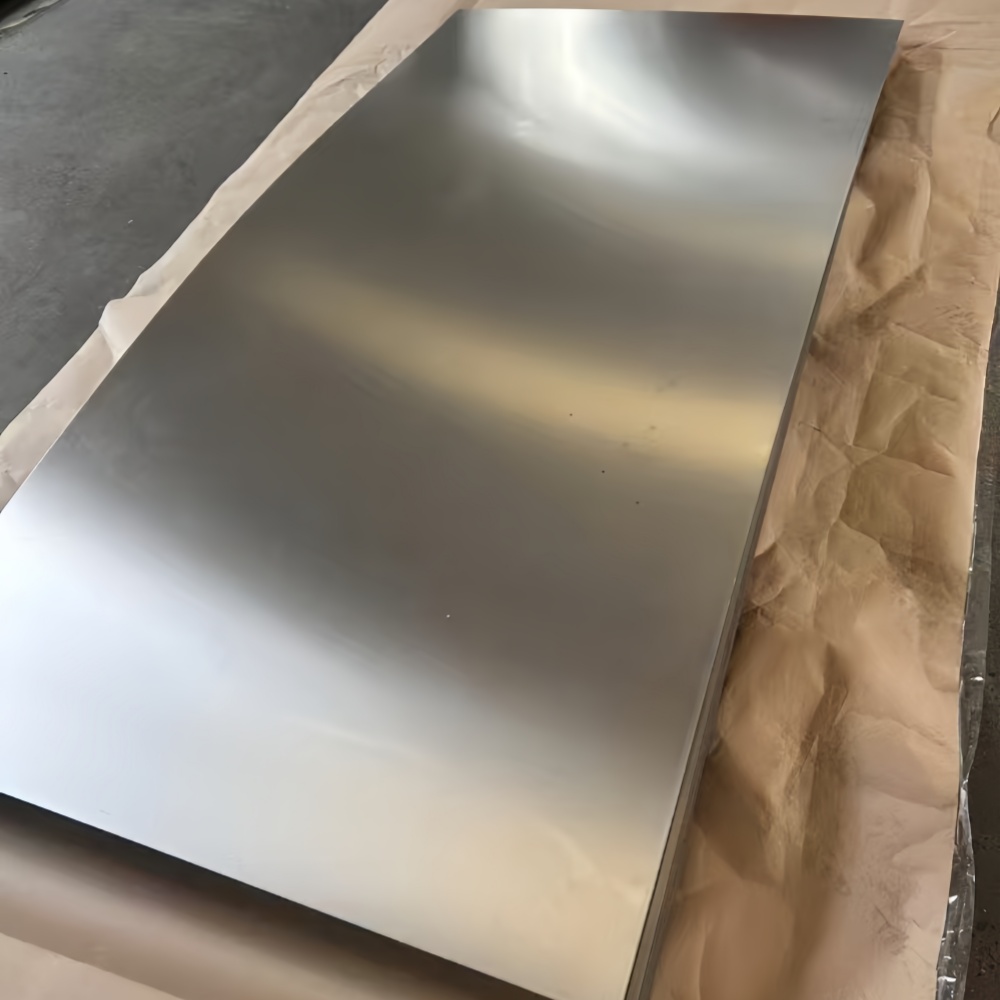

A few days ago, when I was producing titanium cutting boards for customers. When the laser cutting is complete, the titanium cutting board is left overnight and then fully bent. When you look at these bent titanium cutting boards, the first thing you think is residual stress.

What is residual stress? The official definition of residual stress refers to the self-equilibrium internal stress that remains in the body after the elimination of external forces or uneven temperature fields. Both machining and strengthening processes can cause residual stress. Such as cold drawing, laser cutting, cutting, rolling, shot peening, casting, forging, welding and metal heat treatment, due to uneven plastic deformation or phase change may cause residual stress.

This definition is not very clear. Let's put it in everyday colloquial terms. It's not exact, but it's graphic. Just like we use rubber bands. When the stretched rubber band is released, it will shrink back, and when it is pulled back, the rubber band will twist. When metal materials are forced to deform during processing, there is also a "resistance force" inside. Even if the external force disappears, this "resistance" remains inside the material, forming an invisible "stress field".

Where does the residual stress come from? There are three main reasons for this:

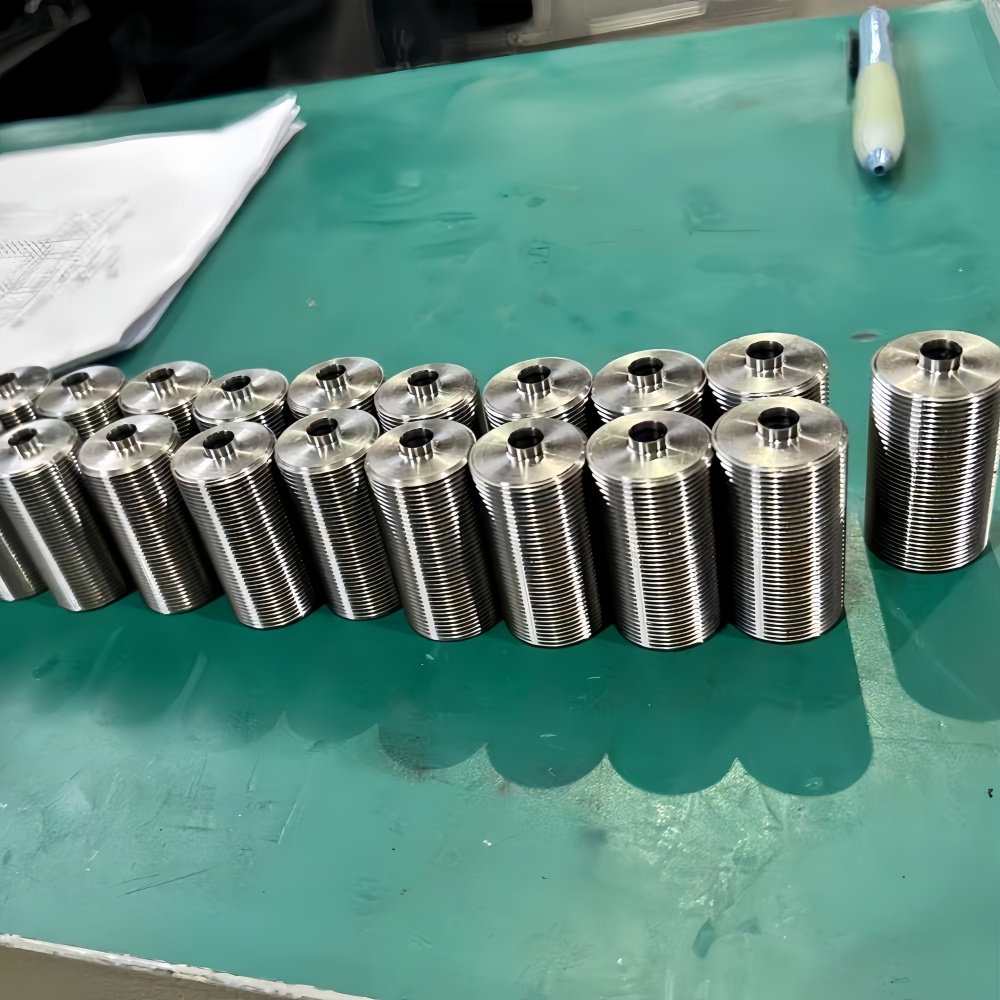

1 The reason for machining: the turning tool cuts the metal, the part that is cut off releases the stress, and the part that is left is forced to "twist".

2. "Ice and fire" alternating between hot and cold during processing.

For example, high temperature zone and low temperature zone of weld during welding. Like the expansion of the road surface exposed to the sun, the surrounding low temperature area is like the contraction of the water pipe in winter, and the heat and cold struggle to produce stress.

3. Metal material phase change stress causes "transformation sequelae". When the metal is cooled, the structure changes and the volume changes asynchronously, resulting in deformation.

There are three main destructive forces of residual stress:

1 Cause changes in the size and shape of the object.

2 Shorten the service life of the parts.

3 Reduce the corrosion resistance and fatigue strength of the metal.

How can the residual stress be removed? As the most commonly used methods there are three:

1 Natural aging: The metal workpiece is placed in the natural environment, through the temperature change and climate action to promote the natural release of internal stress , mainly used to improve the dimensional stability of the material.

2 Heat treatment: is to use the thermal relaxation effect of the residual stress to eliminate or reduce the residual stress, generally using annealing, tempering and other ways to deal with.

3 Vibration aging: refers to a method commonly used in engineering materials to eliminate its internal residual internal stress, through vibration, so that the internal residual internal stress of the workpiece and the additional vibration stress vector and reach more than the yield strength of the material, so that the material has a small amount of plastic deformation, so that the internal stress of the material can be relaxed and reduced.

Residual stress is an unavoidable phenomenon in mechanical manufacturing, which has an important effect on the size, life, plasticity and corrosion resistance of the product. Therefore, how to reduce the residual stress of the product in the process of mechanical manufacturing needs to be concerned about the whole process of product design, manufacturing and production, and take corresponding measures to control and eliminate it. Mastering the law of residual stress is the basic requirement of producing a high-quality product.