Titanium wire as ordinary people, generally rarely seen. But what we usually see is wire. Iron wire is everywhere in our life. Titanium wire is used in industry as much as iron wire is used in life.

Titanium wire is a silver-white metal (laboratory), which has many excellent properties. Titanium has a density of 4.54g/cm3, which is 43% lighter than steel. The mechanical strength is about the same as that of steel and twice that of aluminum. Titanium is high temperature resistant and has a melting point of 1942K, which is nearly 500K higher than steel.

Titanium wire, from subtle medical treatment to the vast space, from petrochemical industry to daily sports and leisure, all show its unique charm. Especially with the rise of 3D printing technology. In particular, more than 60% of titanium and titanium alloy wires are used as welding wires, which are like links to the industry, carrying a strong and reliable mission.

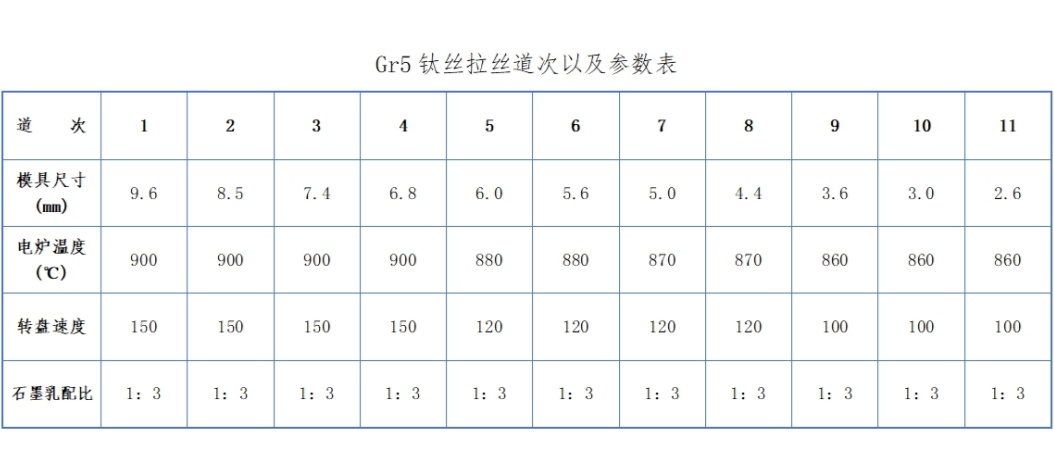

Today we mainly talk about the production of titanium wire manufacturing reference φ2.6mm titanium wire. Titanium wire production process: titanium ingot - 150 - sawing breakdown - rolling round rods (80 mm) - remove black (skinned) - rolling phi 10 mm plates - remove black - check grinding - section drawing more stretch (11) -- - the final annealing product (2.6 mm) phi - closed.

Titanium wire is mainly used by the process: wire drawing. Wire drawing (fixed die drawing) refers to a processing method in which the wire passes through the die hole under a certain tensile force, "plastic deformation occurs, so that the section is reduced and the length is increased". Under the action of drawing force, the wire rod or wire blank is slowly pulled out, and after fine carving of the mold, it finally becomes a small section of titanium wire.

Wire drawing (fixed die drawing) methods are divided into two types: hot drawing, drawing above the recrystallization temperature is hot drawing. Cold drawing, drawing at room temperature is cold drawing. Today we mainly use hot drawing as the main process to illustrate. The main factors affecting the process of hot drawing: temperature, mold, lubricant, speed, etc., have an impact on normal drawing.

Temperature: When hot drawing, the titanium wire should be heated before entering the die hole, mainly heated by electric furnace. The temperature is too high, the heat generated by the stretching metal wire is not easy to take away, the temperature of the metal wire and the mold is increased, the wire is easy to oxidize and change color, and the service life of the mold is reduced: the temperature is too low, the viscosity rises, and it is not conducive to stretching, so the appropriate temperature must be used when drawing the wire.

Mold: It is the most important tool in the drawing process. The main material of the drawing mold is YG8. The drawing die is generally composed of four areas that are smoothly connected with each other: lubrication area, working area, sizing area and exit area.

Lubricants: mainly pure oil, emulsion, paste and so on. The selection of lubricants is mainly based on many factors such as raw material, mold, surface quality and downstream applications. According to our experience, the best titanium wire is graphite milk.

Drawing speed: should be adjusted according to the titanium wire diameter, material characteristics and mold design to prevent wire breakage.

There are four main quality control methods for titanium wire drawing plates:

1. Use a micrometer with an accuracy of 0.001 to measure the diameter.

2. Visually inspect the surface of the line for burrs, cracks, scratches and oxidation.

3. Use temperature measurement to measure the temperature of the electric furnace to ensure that the temperature meets the process requirements.

4. Strict use of mold and mold repair ledger to ensure that the right mold is suitable for each stretch.

Titanium wire processing after processing. To meet specific application requirements, titanium wire may be subject to surface treatment, such as pickling, polishing or coating.

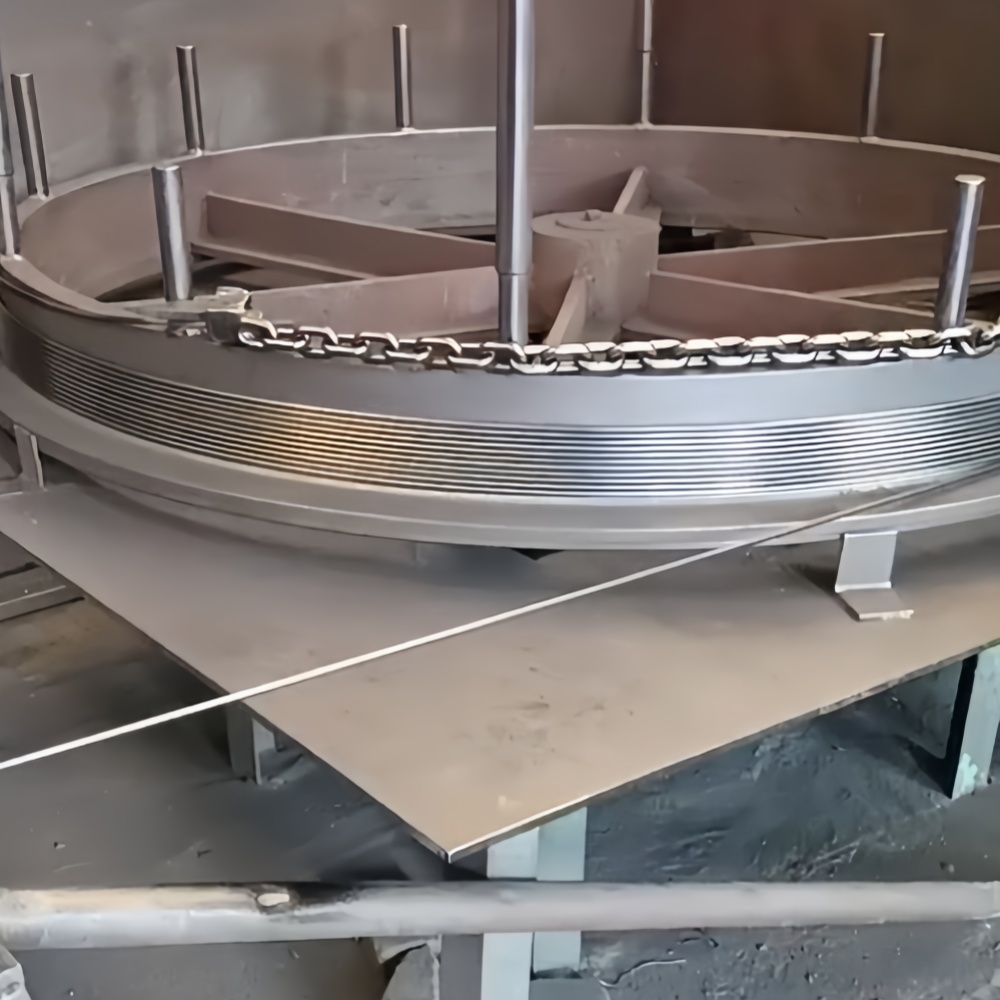

Titanium wire drawing plate production includes raw material preparation, pretreatment, multiple drawing, lubrication and cooling, quality control, and final annealing and winding. These steps are interlinked and together determine the final quality of the titanium wire. In short, strengthen equipment maintenance, optimize process parameters, strengthen technical training and quality management. Only under a full range of measures, can we better ensure high-quality titanium wire, meet market demand, and improve the competitiveness of enterprises.