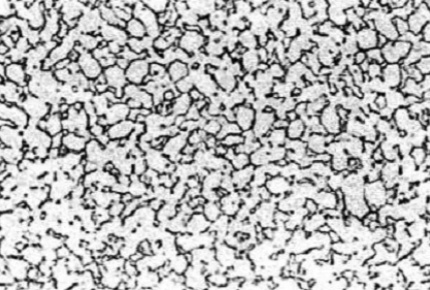

Most people don't know what they mean by metallographic organization. I think the metallographic structure is equivalent to the genetic map of metal materials, and there are different metallographic structures for different metal materials.

When referring to "phase", the first thing that comes to mind is that the lattice structure and the different arrangement of atoms constitute different phases, and the description of it is accurate and scientific, without any specious things. "Structure" reflects a kind of image form of metal microstructure, and its judgment has a certain subjectivity, only qualitative description, without accurate and scientific definition.

Titanium alloys are mainly composed of two phases: α phase (close-packed hexagonal structure) and β phase (body-centered cubic structure). During the phase transition, β-to-α transition (β→α) and α-to-β transition (α→β) are common phase transitions. The α+β biphase titanium alloy represented by TC4(Ti6Al4V) is complex and diverse in structure, including bistate structure, Weil structure, equiaxial structure, basket structure, etc., with different mechanical properties.

Two-state structure: Deformed in the upper temperature zone of the two-phase zone, or reheated to the upper temperature zone of the two-phase zone after deformation and air cooling, can obtain two-state structure. It is characterized by the distribution of isolated primary α particles in the β-transition tissue, and the volume fraction is generally less than 50%. Dimorphic structure refers to two forms when α is the same, that is, the equiaaxial primary α phase and the lamellar secondary α phase in the β transition structure. Duplex structure titanium alloy has higher fatigue strength and plasticity, similar to equiaxial structure, duplex titanium alloy in most cases are two kinds of structures. The difference in the properties of the two tissues is mainly due to the difference in the number of primary alpha phase. The fracture toughness and high temperature properties of the bimodal and equiaxial structures are inferior to those of the Weissberg and basket structures. With the increase of the number of primary α phase, the section shrinkage and fatigue limit increase, while the change of strength is not obvious, and the creep resistance and permanent strength decrease. When the number of the initial phase reaches a certain proportion, the increase and change of section shrinkage is not obvious.

Weil structure: low plasticity and further deterioration after intensive heat treatment. However, its fracture toughness is significantly better than that of the equiaaxial structure, because the existence of α phase at the grain boundary reduces the tendency of intergranular fracture. At the same time, due to the different orientation of α sheet, when the crack expands along the interface of α phase and β phase, it constantly changes the direction and increases the crack growth path, thus restraining crack growth. In addition, the creep resistance and lasting strength of the Weil structure are high, which is due to the coarse grain size. The persistent strength of Weil tissue is closely related to the number and distribution of secondary α phases. If the number of lamellar secondary α phases is small and the distribution is not dispersed enough, the persistent strength of Weil tissue will decrease.

Equiaxed structure: The biphase titanium alloy is deformed in the two-phase region of 30℃ ~ 50℃ below the β phase transition point, and the equiaxed structure can be obtained. It is characterized by the distribution of a certain amount of β transition structure in the primary grain structure of equiaxed α with a content of more than 50%. The lower the deformation temperature, the more the primary α phase and the higher the dislocation density. With the decrease of deformation temperature and the increase of deformation amount, the recrystallization of matrix structure is insufficient, resulting in the elongation of α grain and β transition structure along the deformation direction. The deformed structures can be changed into equiaxed structures by recrystallization annealing in two-phase zone. When the deformation temperature is low enough, the β phase is stable enough, and no phase transition occurs during cooling, and its shape is approximately granular. If the heating temperature is high enough to the upper temperature of the two-phase zone and the cooling rate is slow enough, the secondary α phase precipitates along the primary α phase boundary and connects with each other, and the β phase is distributed irregularly in the α grain boundary. The properties of isaemic and bimodal structures are similar, but the difference is only with the number of primary α phases.

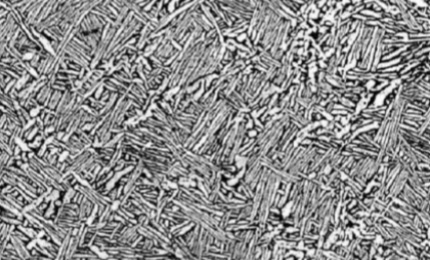

Basket structure: When the biphase titanium alloy is deformed near the β transition temperature, or when the deformation begins in the β single-phase region, the deformation ends in the two-phase region and the deformation amount is 50% to 80%, the basket structure is generally obtained. It is characterized that the original β grain boundary is destroyed in the deformation process, or a small amount of granular grain boundary α is produced, and the α sheet in the original β grain becomes shorter, and each sheet is interleaved in a braided net basket. Net basket structure plasticity is higher, usually can meet the requirements of use, fatigue performance is also higher, but the fracture toughness is low.

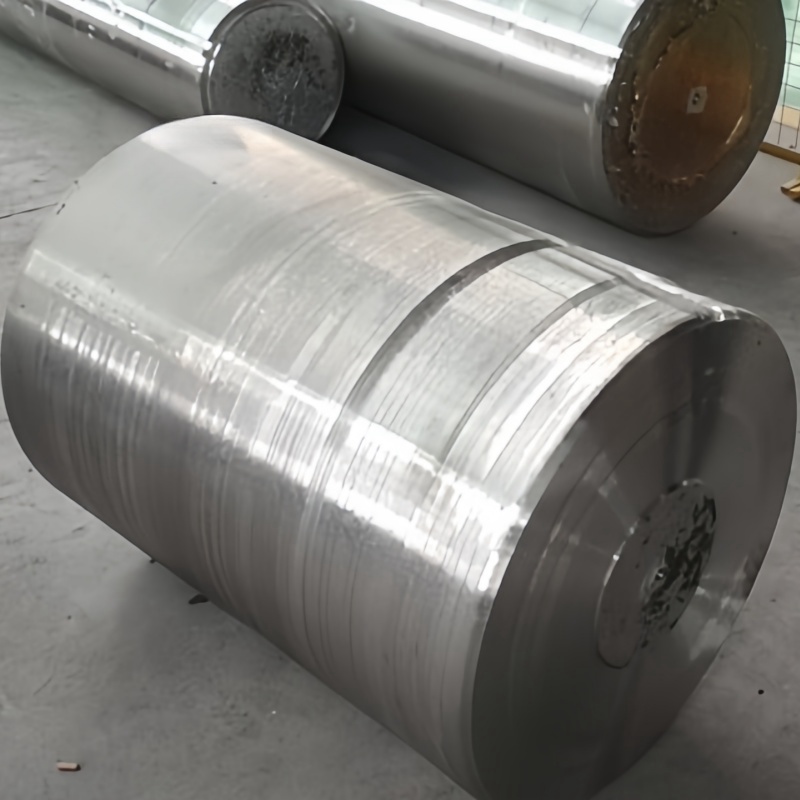

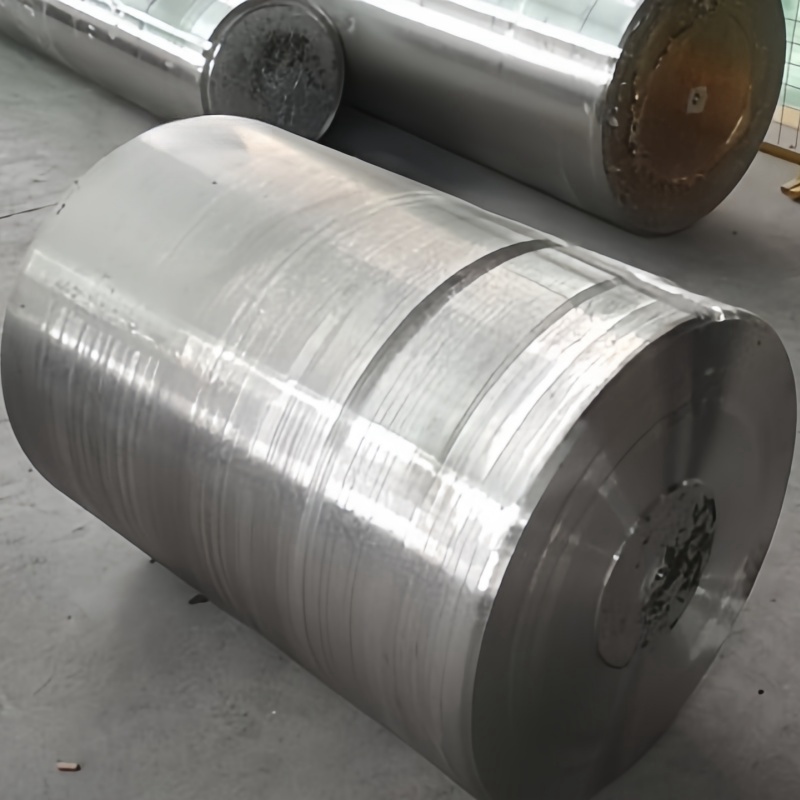

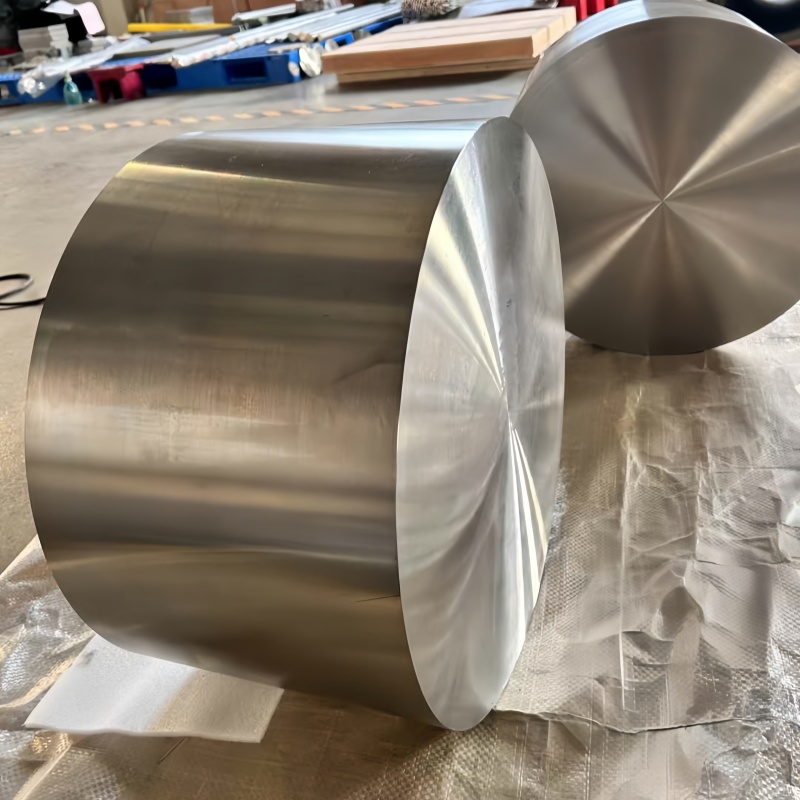

Titanium and titanium alloys to obtain satisfactory metallographic organization is a more troublesome process, in order to obtain products that can meet customer needs. We need to have strict control over each production process. For example: vacuum melting, forging, heat treatment and other key processes. Any point needs to be focused on. We need to strictly implement the requirements of the process, but also comply with the requirements of the quality system to ensure that the final result can achieve the best results.