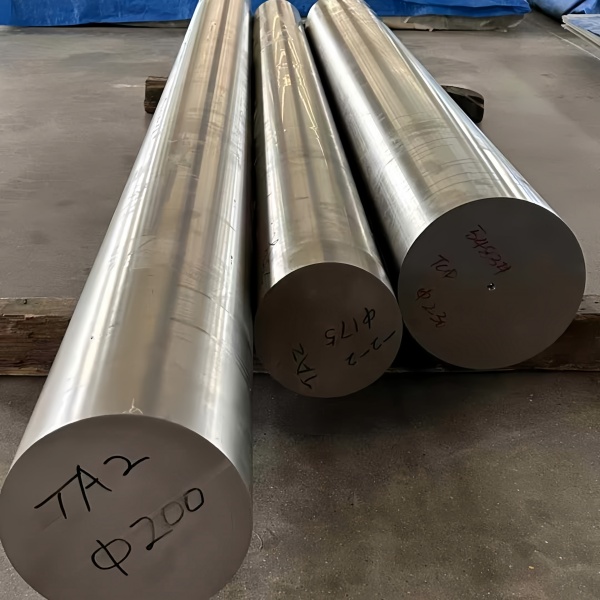

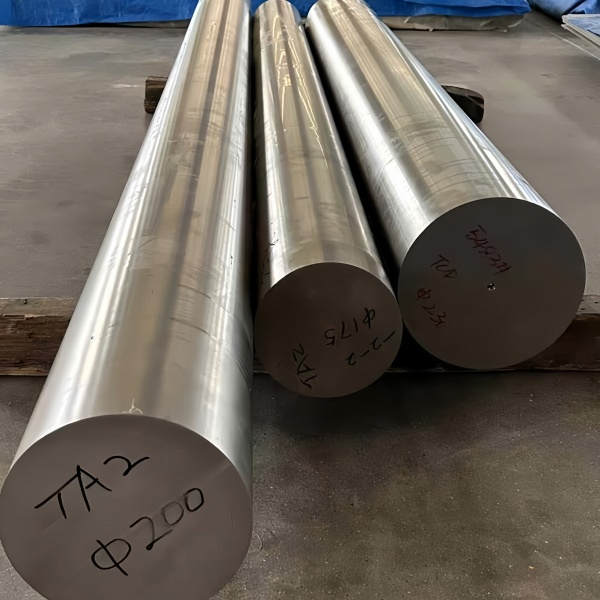

I remember that in 2015, an old customer suddenly gave abnormal feedback: the titanium core was overheating. Our team had no idea. Do not know what is burning, look up the material turned over the textbook, in a pile of materials finally found.

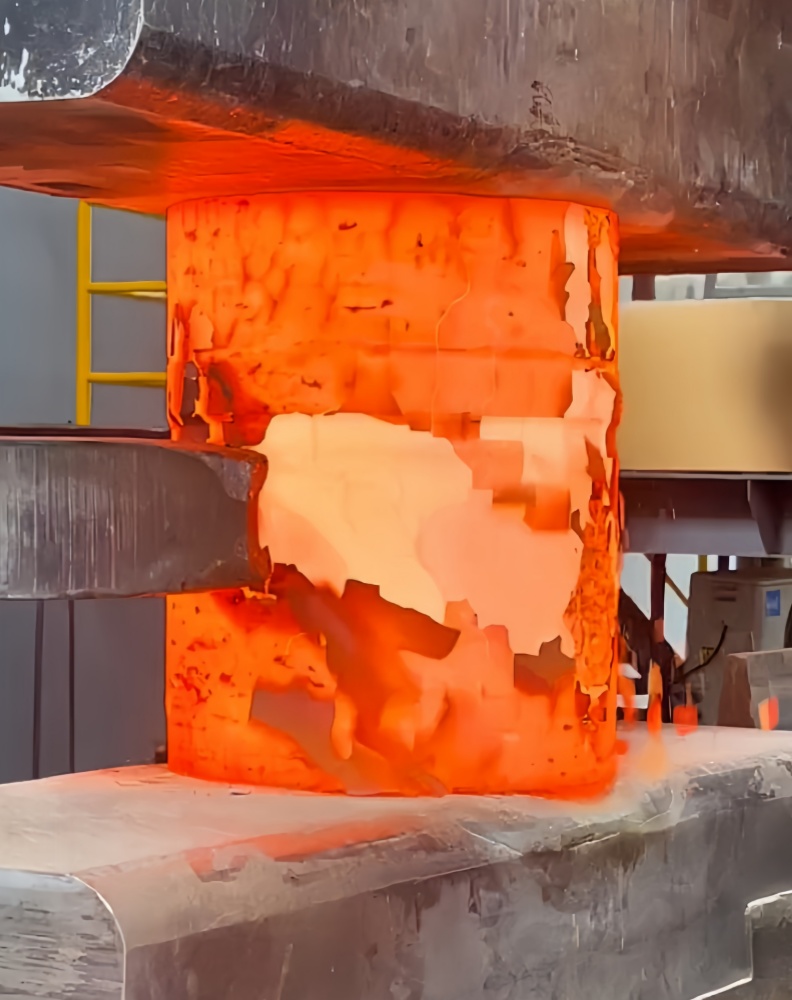

The overheating of titanium alloy material refers to the phenomenon that the austenite grains of the material are abnormally coarse due to the high heating temperature or the long holding time during the heat treatment process, which deteriorates its mechanical properties. Overheating usually occurs below the solid phase line of the material, when the material does not melt, but the excessive growth of the grain seriously affects the plasticity, toughness and strength of the material.

one Titanium alloy material overheating characteristics:

Macroscopic performance: The surface of the superheated material may not change significantly, but the internal grain has been significantly coarse.

2. Microstructure: Under the microscope, it can be found that the austenite grains of the superheated materials are abnormally thick, the grain boundaries are widened, and even abnormal structures such as westenitic structures appear.

3. Mechanical properties: The plasticity, toughness and strength of the superheated material will be reduced, but it can usually be recovered to a certain extent by subsequent heat treatment measures.

Titanium alloy material overheating effect:

Overheating mainly affects the mechanical properties of the material, reducing the plasticity, toughness and strength of the material. Can be overheated .It can lead to cracks, deformation and other defects in the subsequent processing and use of the material.

Titanium alloy material overheating prevention measures:

1 one Strictly control the heating temperature and time: in the heat treatment process, the heating temperature and time should be strictly controlled to avoid overheating or over-burning caused by too high temperature or too long holding time.

2. Improve the accuracy and stability of the equipment: Establish the effect ledger of the heating equipment to ensure the accuracy and stability of the heat treatment equipment to avoid overheating or overburning caused by equipment failure or error.

3. Strengthen material testing: Conduct detailed testing and analysis of materials before and after heat treatment, including metallographic inspection, mechanical property testing, etc., in order to find and deal with overheating or overburning problems in time.

4. Optimize the heat treatment process: according to the composition and performance requirements of the material, select the appropriate heat treatment process parameters, such as heating rate, holding time, cooling method, etc.

Titanium alloy material overheating detection overheating method:

one Low coarse crystal inspection: The general use of 1:1 hydrochloric acid aqueous solution hot etching. For the arc steel with poor material purity, the cold etch agent such as 10% ~ 20% persulfuric acid ammonia solution is used, and the effect is better. According to the degree of overheat, it can be observed with the naked eye that there are scattered flashover grains in slight overheat; Generally, the grain is flake or polygon when it is overheated. When severely overheated, it is snowy. At present, there is no unified test standard for low power.

2. Metallographic analysis: electrolytic corrosion or chemical corrosion is carried out on the polished metallographic sample with etchants, and then the characteristics of overheating and overburning are observed at and near the grain boundary under a metallographic microscope to determine whether the steel is overheating and overburning.