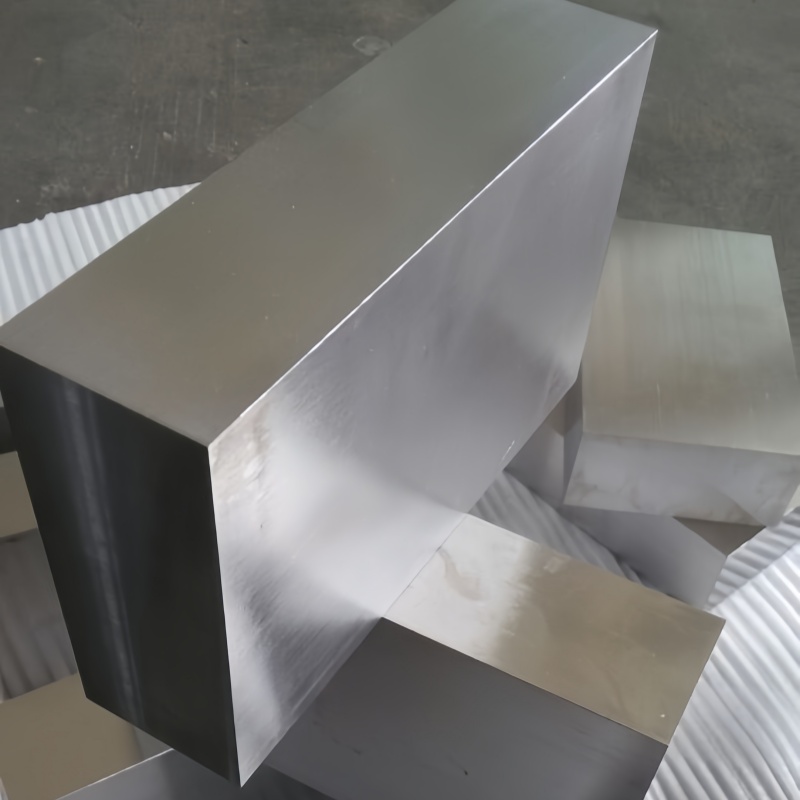

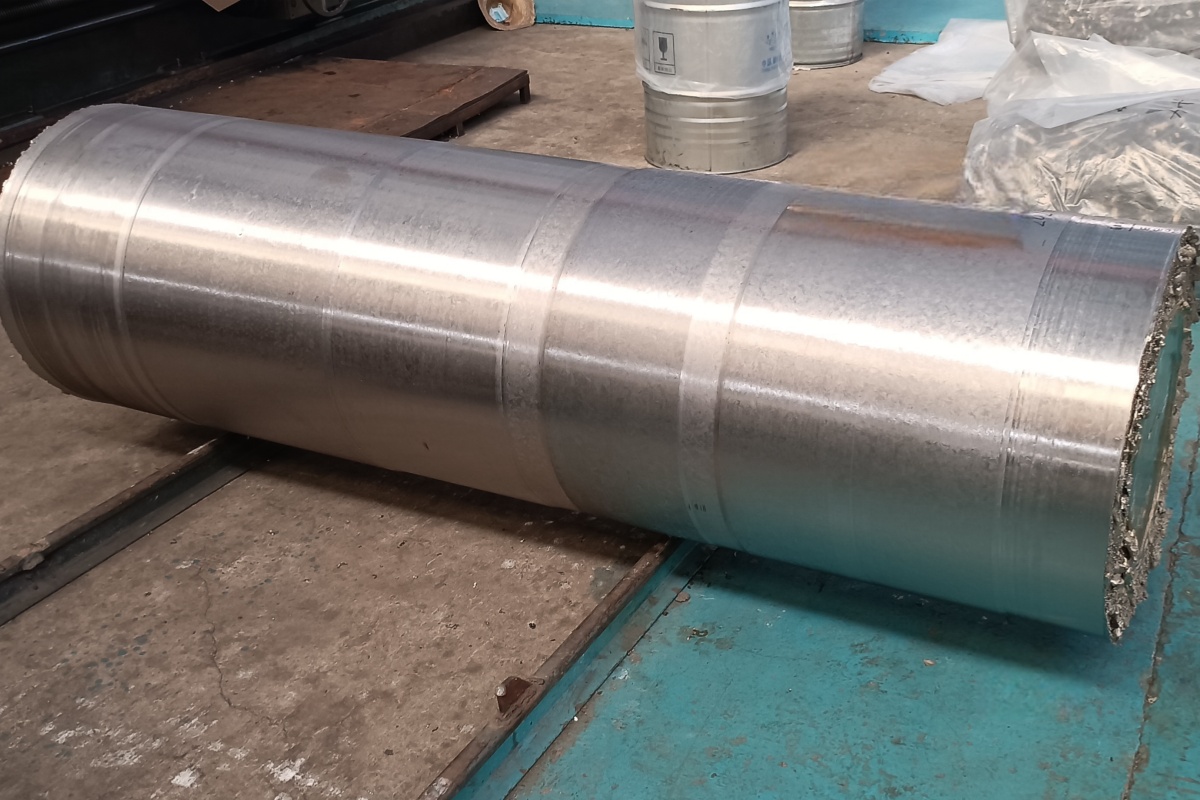

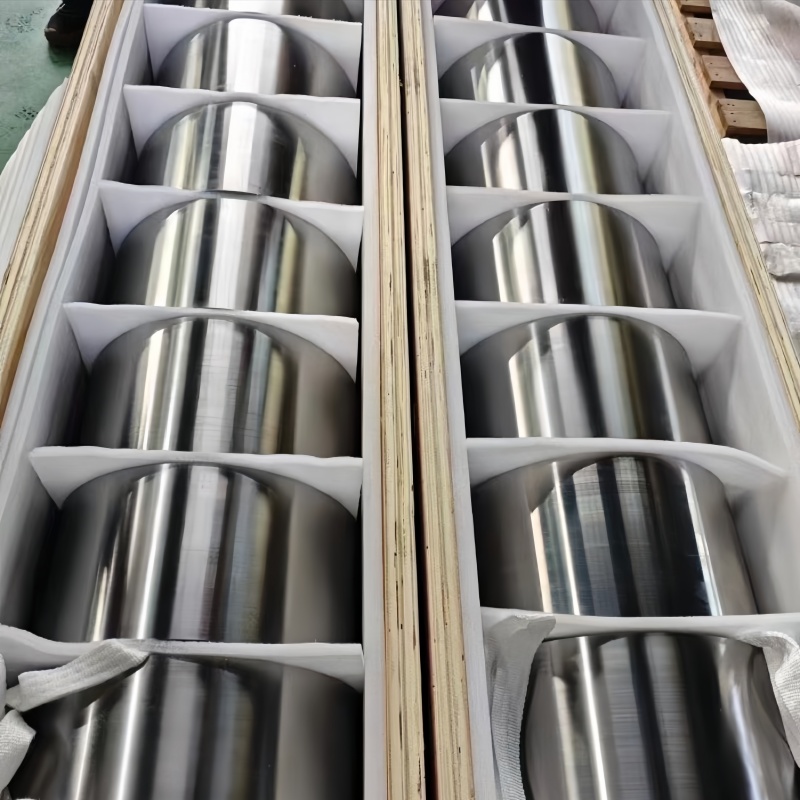

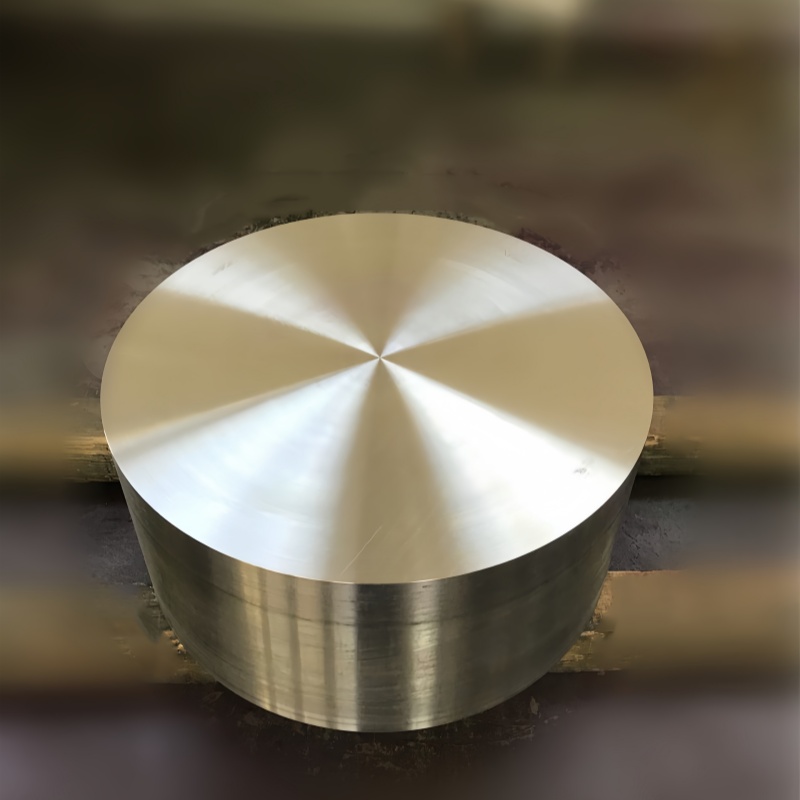

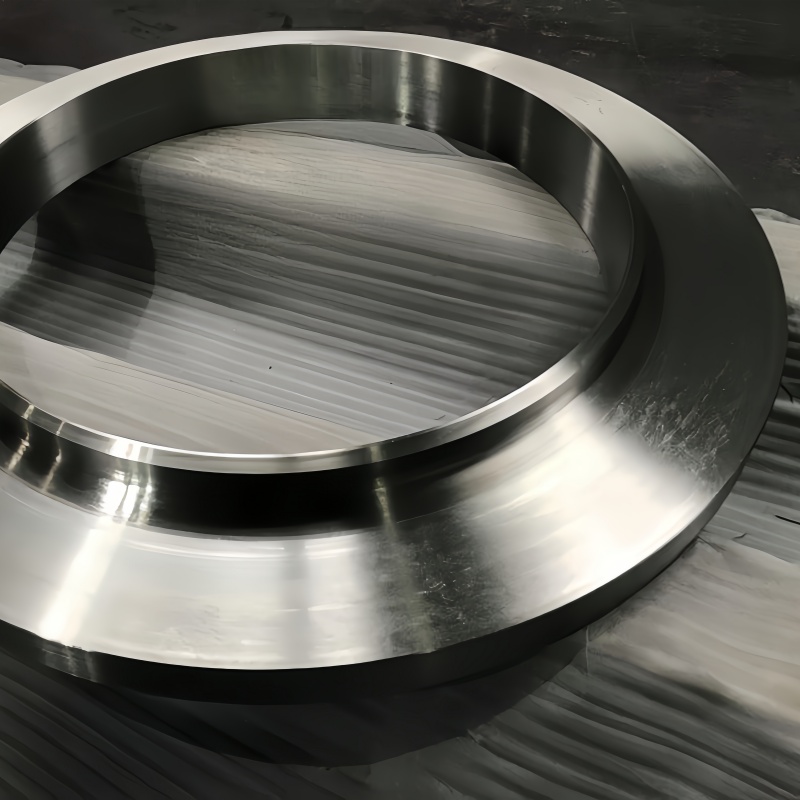

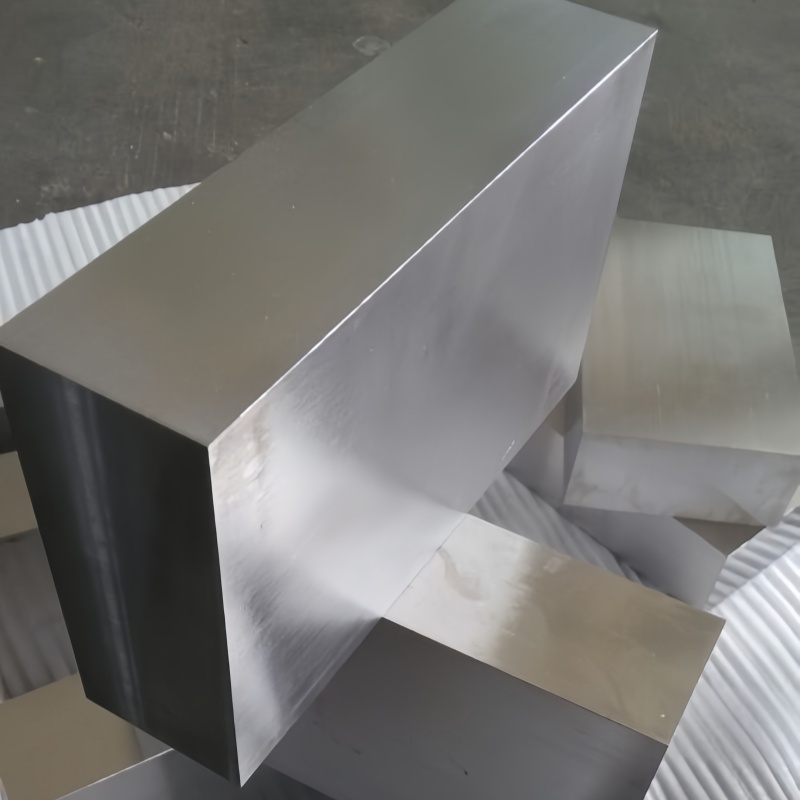

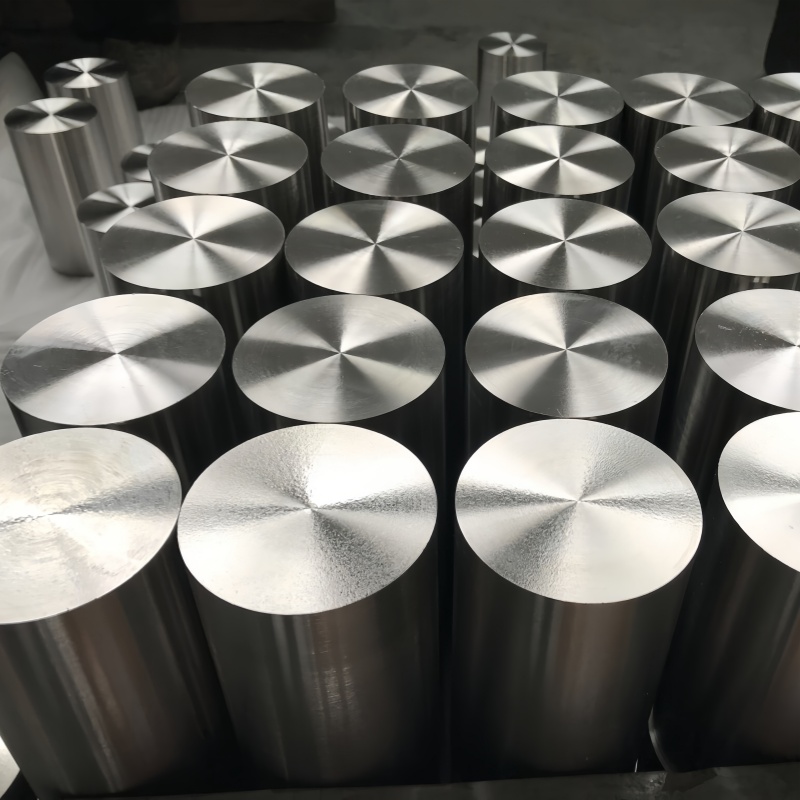

Titanium and titanium alloys have the advantages of non-toxicity, light weight, high specific strength and good biocompatibility, and are widely used in aerospace, petrochemical, food and medical fields. However, the defects of titanium and titanium alloys such as low hardness, poor wear resistance and poor high-temperature oxidation resistance limit the further development of titanium alloys.

How to change the defect of titanium and titanium alloy. You have to use chemical heat treatment, or chemical modification. Chemical heat treatment is a metal heat treatment process that uses chemical reactions and sometimes physical methods to change the chemical composition and organizational structure of the surface layer of steel in order to obtain better technical and economic benefits than homogeneous materials.

There are four most commonly used chemical heat treatment methods for titanium and titanium alloys: titanium nitriding, carburizing, boronizing and metallizing.

After nitriding treatment, high hardness nitrides such as TiN and Ti2N are formed, which have excellent corrosion and wear resistance. Common nitriding technologies include salt bath nitriding, gas nitriding, ion implantation nitriding, double glow plasma nitriding, surface laser nitriding and vacuum nitriding.

Carburizing treatment can obtain carbides on the surface of titanium alloy and improve its hardness and wear resistance. Due to the dense passivation film on the surface of titanium alloy and low atomic diffusion coefficient, the carburizing process is more complicated, requiring higher temperature and more complex technical control . Titanium and carbon can form a TiC strengthening phase. Titanium alloy carburizing includes solid carburizing, ion carburizing, gas carburizing and laser carburizing. Solid carburizing technology is more traditional, the method is simple, low cost, more economical and practical. However, it is difficult to control the oxygen concentration, the carburizing layer obtained is not uniform, and the thickness of the carburizing layer is small.

Boronizing can form borides on the surface of titanium alloy, further improving its hardness and corrosion resistance. This method is commonly used in applications that require extremely high hardness and wear resistance . The main compounds formed by titanium and boron are TiB and TiB2. Titanium alloy boronizing technology also includes solid method, liquid method and gas method, of which solid boronizing technology is divided into powder method and paste method, liquid boronizing technology is divided into molten salt impregnation method, molten salt electrolysis method, fluidized bed boronizing method. Gas boronizing technology can be divided into ion boronizing and double glow plasma boronizing.

Metallizing can improve the properties of titanium alloys by penetrating other metal elements into the surface to form a composite material. For titanium alloys, the choice of pre-permeated metal elements is very wide, such as a metal element with excellent tribological or corrosion properties can be selected, but the premise is that this metal element has good solid solubility with titanium alloys. According to the theory of metallics, there are many factors affecting the solid solubility of metals, including atomic size, chemical affinity, crystal structure, relative valence and so on.

In summary, the chemical heat treatment methods and advantages of titanium alloys are different, and different processes are selected for different needs. At present, nitriding and carburizing technology are widely used. With the continuous development of titanium and titanium alloy technology, titanium alloy surface treatment will also usher in great development. Titanium and titanium alloy products will be given higher performance.