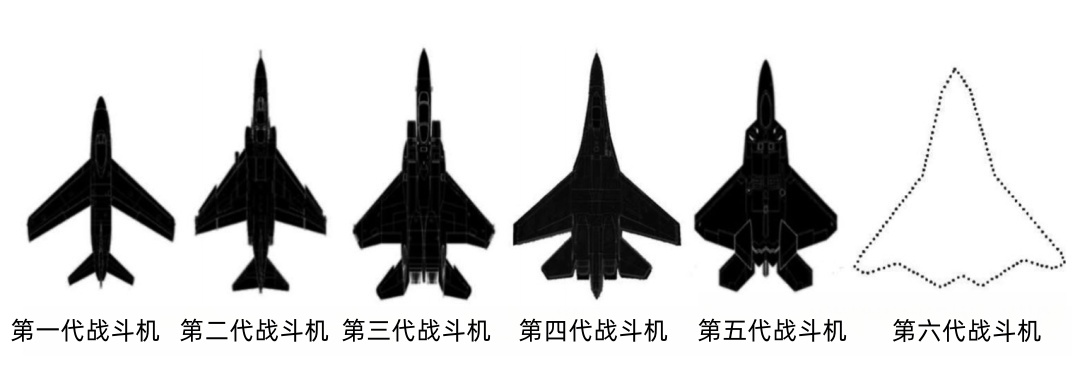

Recently, rumors about the successful first flight of China's sixth-generation fighter jet have become a hot topic of concern. If the world's first fifth-generation fighter jet - the United States F-22 first flew in 1997, it has been 27 years, and now many countries are carrying out the development of sixth-generation fighter jets.

As the advanced achievement of modern aviation technology development, the sixth-generation fighter aircraft has high requirements for material properties. With its excellent strength, weight ratio, corrosion resistance and many other excellent properties, titanium has become an indispensable material for key parts such as the fuselage and engine of sixth-generation aircraft.

Titanium alloy due to low density, high specific strength, corrosion resistance, high temperature resistance, no magnetic, weldable, wide temperature range (-269℃-600℃) and other excellent properties, and can carry out a variety of parts forming, welding and machining, in the aviation field is soon widely used. In the early 1950s, military aircraft began to use industrial pure titanium manufacturing after the fuselage of the heat shield, tail cover, deceleration plate and other structural parts with small forces. In the 1960s, titanium alloy was further applied to the main stress structural parts of aircraft flap rails, load-bearing spacer frames, center wing box beams, landing gear beams and so on.

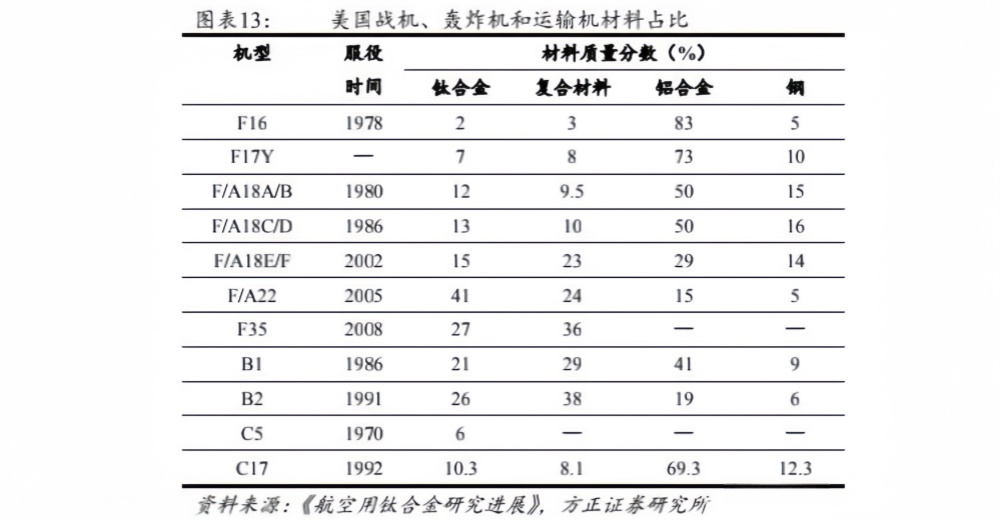

Taking the US F14 fighter as an example, titanium alloy accounts for 26% of the weight of the F14 fighter structure, and components made of titanium include the wing structure, landing gear components, tail structure, as well as small fasteners, springs and hydraulic pipes.

In terms of military aircraft, the amount of titanium used by foreign advanced fighters accounts for about 25% of the total mass of the body structure. The United States F-35 aircraft titanium consumption of 27%, F-22 aircraft titanium consumption of up to 41%, its fuselage main bearing beam and frame made of titanium alloy, creating the highest record of fighter titanium consumption so far. The US B1 bomber and B2 bomber use of titanium alloy is 21% and 26%, respectively. The amount of titanium used in American transport aircraft has also increased from 6% of the C5 in early service to 10.3% of the C17, and the amount of titanium used in Russia's Ilyushir 76 transport aircraft has reached 12%.

Domestically, military fighters from the initial titanium content of only 2% of the J-8, gradually increased to the titanium content of 4% of the J-10, the titanium content of the J-11 increased to 15%, and the titanium content of the J-20 reached 20%. The titanium alloy content of the large military transport aircraft Y-20 is 10%, which is comparable to the titanium alloy content of the advanced C-17 transport aircraft in the United States. On civil aircraft, the titanium alloy consumption of commercial airliner ARJ21 is 4.8%, while the titanium alloy is widely used in C919 large passenger aircraft, and the amount of titanium has reached 9.3%, mainly for the nose, suspension, tail, outer and central wing box.

As the advanced achievement of modern aviation technology development, the sixth-generation fighter aircraft has high requirements for material properties. With its excellent strength, weight ratio, corrosion resistance and many other excellent properties, titanium has become an indispensable material for key parts such as the fuselage and engine of sixth-generation aircraft.

In the test flight stage, the inspection of various properties of titanium is more strict and accurate, which not only helps to optimize and improve the production process of titanium, but also provides an excellent display platform for the wide application of titanium. It is recalled that the J-20 first flew successfully in January 2011, and was formally installed in October 2019. The test flight and installation of J-20 has led to the development of a number of titanium production and manufacturing enterprises. A new round of titanium is to start with this project as a starting point, from 2016 to 2022, led to the eight-year gold growth period of titanium, the main domestic titanium production enterprises to sprint aviation and aerospace projects, and the transfer of production technology and products to the civilian field, led to the rapid development of the entire industry.

It is expected that after the test flight of sixth-generation aircraft, the annual use of domestic titanium materials will achieve a considerable increase in percentage on the existing basis. At the same time, the new market demand will stimulate more funds to pour into the titanium industry, and further promote the scale expansion and industrial upgrading of titanium enterprises. For China's overall aerospace industry, the growth of titanium demand under the test flight of sixth-generation fighters is a key development opportunity. This collaborative development model will further enhance China's competitiveness in the global aerospace field, provide a strong driving force for the production and manufacturing of titanium materials technology and equipment level, and will certainly promote China's titanium manufacturing level and output as well as the level of aerospace science and technology to a higher level.