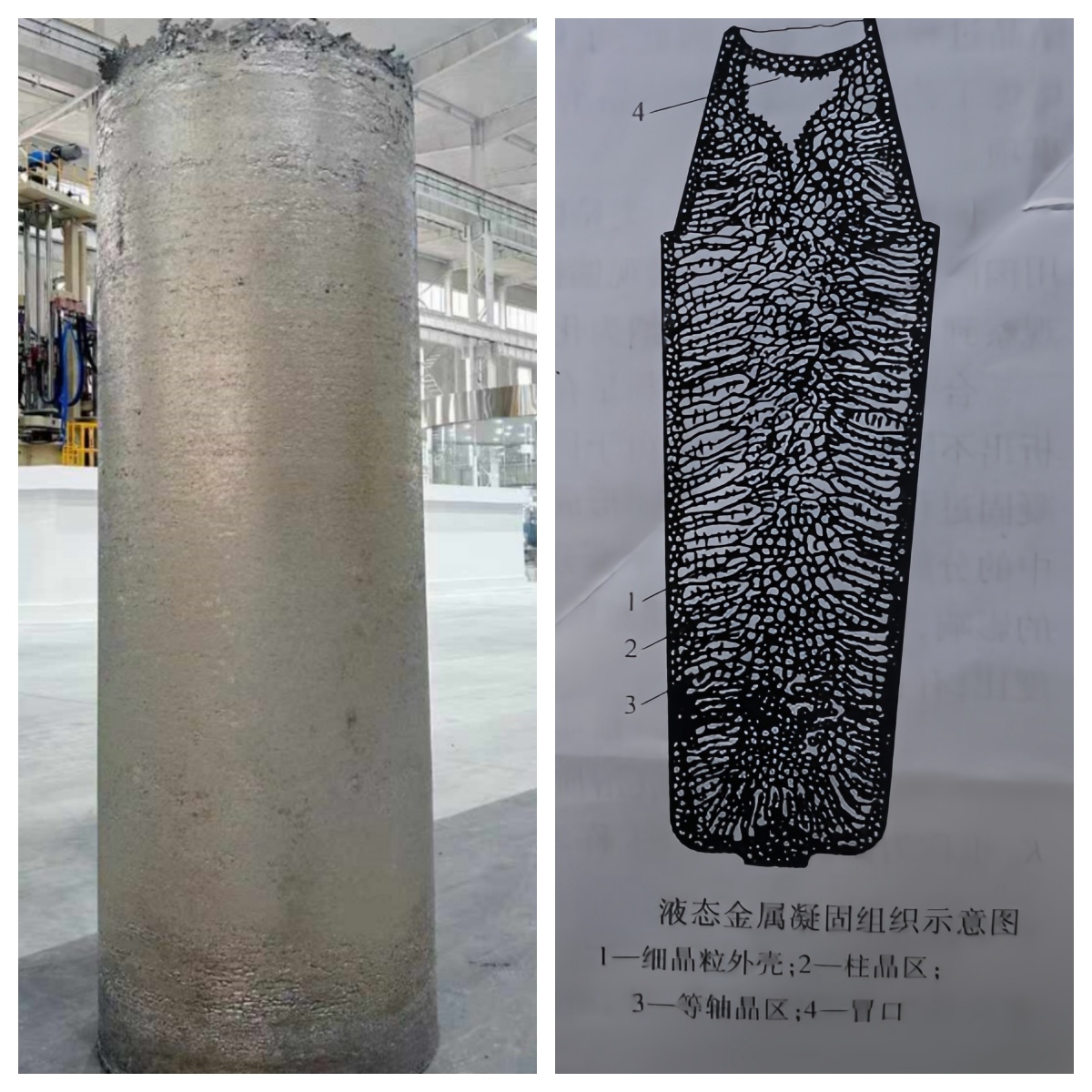

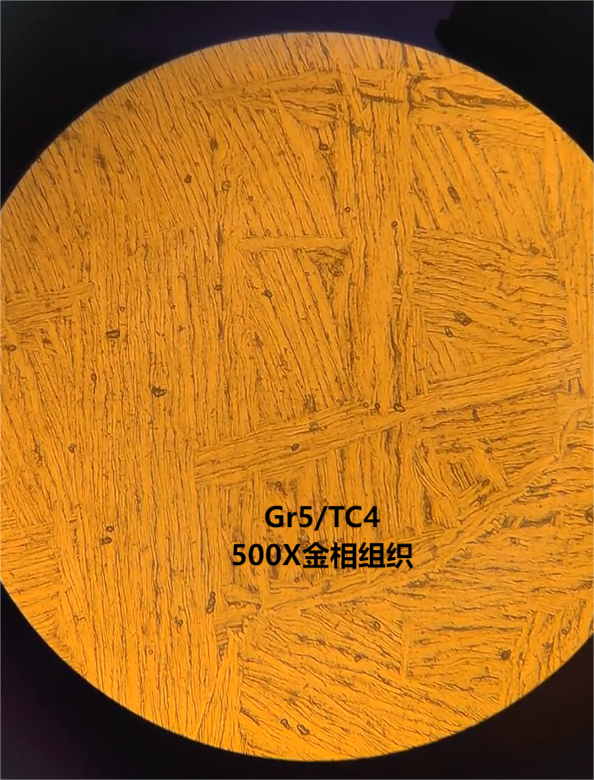

The product of vacuum consumable arc melting is called titanium ingot. Titanium ingot is actually a product that produces a large number of crystals quickly, and the microstructure formed under different conditions is not the same. Titanium ingot is a typical solidification structure of liquid metal.

In order to eliminate the defects of the metal in the smelting process and optimize the microstructure, forging technology has to be adopted. To put it bluntly, the grain size of titanium ingot is refined and the coarse grain is broken. The titanium ingot can not only obtain the shape required by the mechanical parts, but also improve the internal organization of the material and improve the mechanical properties of the mechanical parts.

There are five characteristics of titanium in forging:

1, large deformation resistance at forging temperature titanium alloy deformation resistance is higher than steel. At the same time, the deformation resistance of titanium alloy increases with the decrease of temperature much faster than that of steel. When forging titanium alloy, even if the forging temperature is slightly reduced, the deformation resistance will be greatly increased.

2, the thermal conductivity of titanium alloy is worse than that of steel, aluminum and other metals, and the thermal conductivity of titanium alloy is 1/5 of iron and 1/12.5 of aluminum. As a result, the surface of the forged billet cools quickly after it is released.

3, large viscosity, poor fluidity Compared with steel, titanium alloy viscosity is large, poor fluidity.

4, titanium is very active at high temperatures, and it is easy to compound with oxygen, nitrogen, carbon and other elements.

5, according to the extensive practice and scientific research in the industry, the forging temperature range of titanium alloy is usually set between 900℃ and 1100℃. In this temperature range, the plasticity of titanium alloy is fully developed, which is conducive to the formation of uniform fine grains and good organizational structure, and then improve the comprehensive properties of the material.

To sum up: In order to perfectly solve the forging process of titanium ingot, large electric furnace, large forging machine, and supporting equipment are needed.

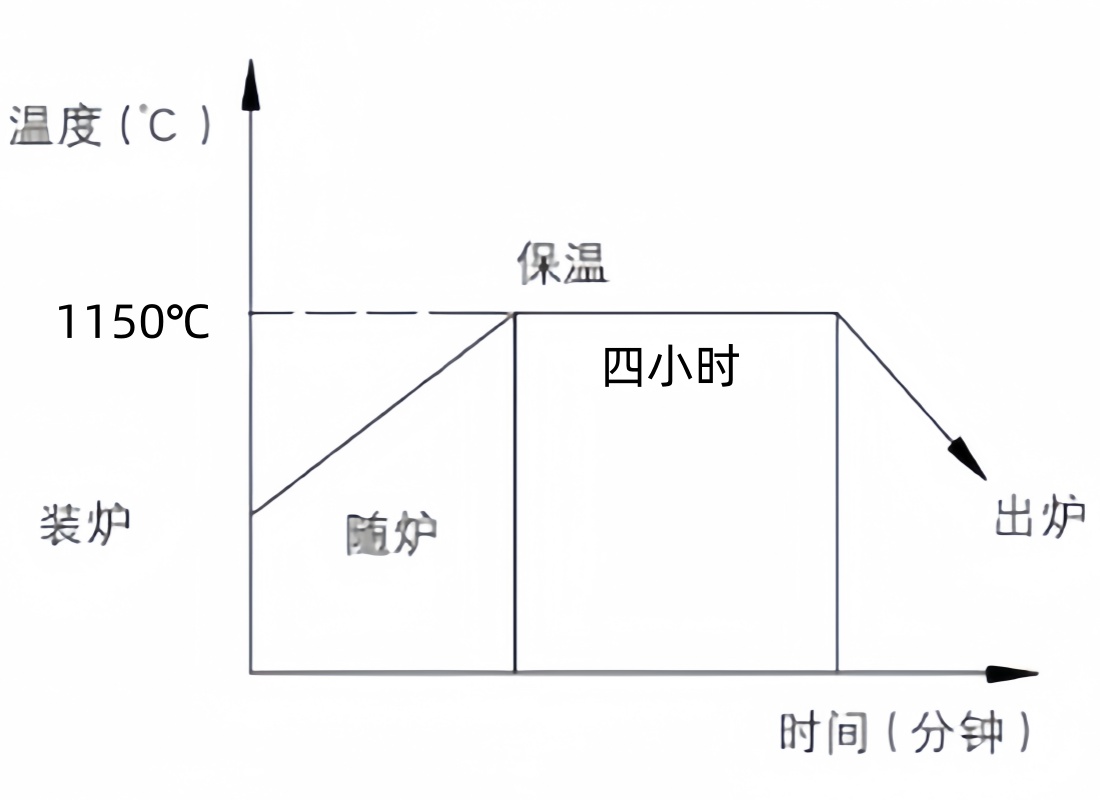

Titanium ingot forging technology mainly includes four processes: furnace loading, heating, forging, cooling.

The factory generally needs 5 groups of electric furnaces, 2 groups of high temperature furnaces, 2 groups of low temperature furnaces, and 1 group of annealing furnaces. Choose different stoves according to different materials. For example, the initial forging temperature of TC4φ560mm titanium ingot is 1150℃, the final forging temperature is 800℃, and the holding time is 5.5 hours.

When forging work, the following aspects need to be considered:

Reference 8000T forging machine Total length * total width * total height =3150mm*8400mm*8000mm, power requirement : 3300kw。Need a larger site to install, as well as professional supporting high-pressure equipment. Forging team At least 8 people are required to complete the forging process.

The cost of forging equipment is high. The operation is more complicated. It requires professional operators to control the forging equipment to ensure the stability of the forging process and product quality. In addition, titanium forging production cycle is long, and supporting equipment and supporting consumables are expensive. High energy consumption, forging process needs to consume a lot of electricity. In summary, the cost of forging processing is too high, resulting in high prices of titanium and titanium alloys.