How to turn "sponge titanium" into titanium. Here we have to mention the "vacuum consumable electrode melting" technology, also known as VAR technology. A method of melting metals by electric arc heating under vacuum conditions.

VAR furnace is composed of vacuum system, electrode driving mechanical system, copper crucible and cooling cycle system, DC power supply, automatic and manual control system, arc stirring system, monitoring and automatic recording system, etc.

The basic flow of VAR melting process is: mixing → pressing electrode → welding into consumable electrode → primary melting → finished product melting → titanium ingot turning → inspection.

You may have noticed the term "consumable electrode". What is self-consumption? What is an electrode? Now it must be introduced here. Before VAR vacuum melting, titanium sponge particles, intermediate alloys and auxiliary materials need to be evenly mixed and pressed into blocks, usually called "electrodes".

After the "electrode block" is pressed, it is necessary to use plasma welding to weld a plurality of pressure blocks into a strip electrode block.

Now create a mental model of a lit candle, turning the candle upside down. The fire goes down. The approximate shape of the VAR vacuum consumable melting method is like an upside down candle, the wax drops are collected together, installed in a fixed shape (copper crucible), and the crucible is cooled, and the ingots and crucible are separated.

During melting, the electrode is melted by using the high temperature generated by the arc discharge between the electrode and the crucible pole as the heat source under vacuum. The electrode is made of the melted metal material, and the consumable electrode is continuously melted in the melting process, while the ingot is continuously solidified from the bottom up in the crystallizer.

Completion of at least two smelting to obtain better quality titanium ingots, for medical titanium and high standard aerospace titanium requires at least three smelting. The crucible is generally made of copper or copper alloy material, and there is circulating cooling water outside the crucible. And the electrified coil arranged around the crucible uses the principle of electromagnetic induction to stir the liquid core and paste area inside the titanium ingot in the state of titanium smelting, improve the composition segregation during the solidification process of titanium alloy, and play a role in refining the grain.

In the smelting process, the vacuum degree in the furnace is as high as 1.3*10-1 pa. At a high temperature of 1668℃, titanium is easy to react with oxygen, nitrogen, carbon and other elements, so the vacuum environment is crucial to ensure the purity of titanium ingot. VAR smelting equipment is more complex, high maintenance and operation costs basically a set of equipment investment base needs nearly 100 million (refer to 6 tons of equipment).

Long production process: electrode preparation is complicated , the need for expensive presses and corresponding facilities. The smelting cycle is long, and the secondary ingot needs at least 8 days production cycle. Three doses take at least 12 days.

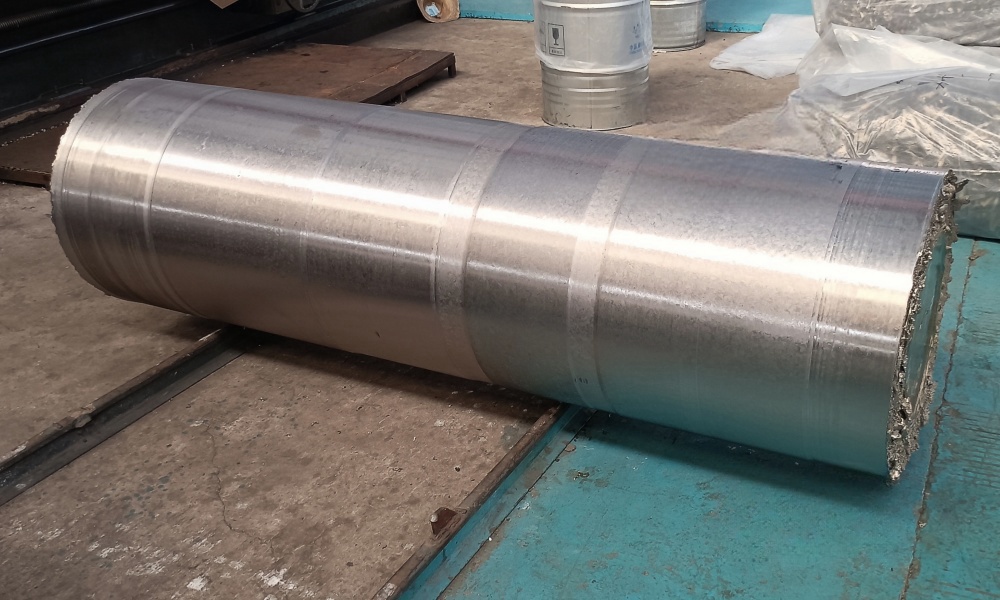

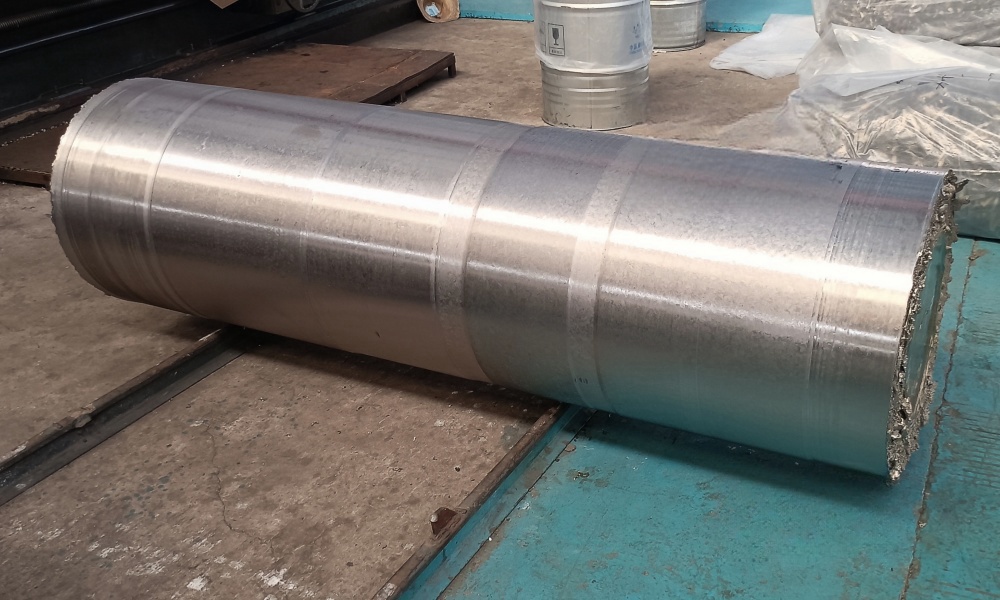

The yield of the whole process of VAR smelting is about 90% lower. After a remelting, the first titanium ingot should be cut off the ingot head and tail, and the surface of the titanium ingot should be milling the oxide layer within 2.5mm. And a secondary remelt in the same way. The composition samples of titanium alloy are generally taken from the sampling slots at the head, middle and tail of the secondary ingot, and the chip samples and block samples are determined by ICP spectrometer.

The equipment for vacuum melting furnaces is expensive. The operation of vacuum melting furnace is complicated. It requires professional operators to monitor and adjust various parameters to ensure the stability of the melting process and product quality. In addition, the production cycle of vacuum melting furnaces is long, and the supporting equipment and supporting consumables are expensive. High energy consumption, VAR melting process requires a lot of power to maintain the vacuum environment and arc discharge. In summary, the smelting cost of titanium ingot is too high, resulting in high prices of titanium and titanium alloys.