We all know that titanium is expensive, but why? Raw materials are expensive, that is, titanium sponge is expensive. Speaking of titanium and titanium alloys, we have to mention titanium sponge. Sponge titanium is the production of titanium and titanium alloy raw materials. Without titanium sponge there would be no titanium and titanium alloys.

Titanium sponge mainly comes from two minerals:

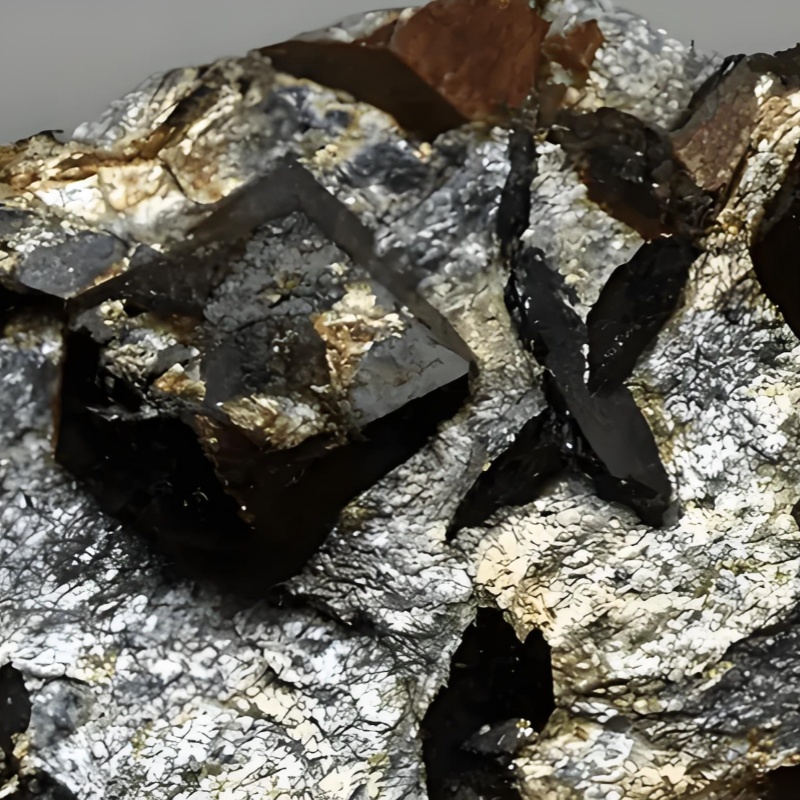

1, rutile is a yellow to reddish-brown mineral, its main component is TiO2, also contains a certain amount of iron, niobium and tantalum.

2. Ilmenite, the theoretical molecular formula is FeTi03, in which the theoretical content of TiO2 is 52.63%. Ilmenite in nature can be regarded as a solid solution composed of FeO-TiO2 and other impurity oxides.

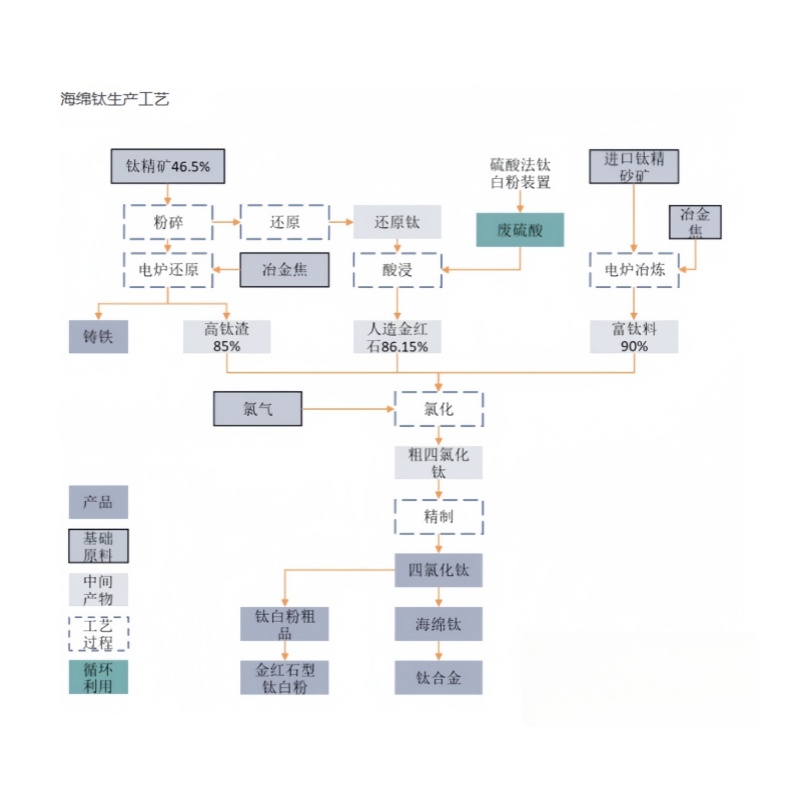

In 1940, Luxembourg scientist W.J. roll produced pure titanium by reducing TiCl4 with magnesium. Since then, magnesium reduction (also known as the Claure process) and sodium reduction (also known as the Hunt process) have become the main industrial methods for the production of titanium sponge. Please note that the production here is "sponge titanium" also known as "porous titanium".The production process of titanium sponge mainly includes the following steps : ilmenite mining, beneficiation, titanium concentrate, enrichment, titanium-rich material, crude TiC1 chloride, refining, pure TiC1, magnesium reduction, crushing, grading, mixing, sponge titanium

The following four processes are critical processes.

Chlorination process : This is the main step in the production of titanium tetrachloride. The specific methods include boiling chlorination, molten salt chlorination and shaft furnace chlorination. Boiling chlorination is the most commonly used method at present. Titanium tetrachloride is produced by the reaction of titanium-rich material with solid carbon reducing agent through high temperature and chlorine gas. Molten salt chlorination and shaft furnace chlorination use molten salt medium and vertical chlorination furnace respectively for chlorination reaction.

refining process : Titanium tetrachloride needs to be refined and purified to remove high and low boiling point impurities. Common refining methods include distillation, which uses an efficient float valve rectification tower, and chemical methods, which use aluminum powder to remove vanadium and other methods.

reduction-distillation process : refined titanium tetrachloride is reacted with molten magnesium at high temperatures to form sponge-like titanium and molten magnesium chloride. Then the magnesium chloride and excess magnesium in titanium sponge are removed by vacuum distillation to obtain pure titanium.

electrolytic magnesium process : Electrolytic magnesium is one of the key steps in the production of titanium sponge. Multipole electrolyser and clap-free magnesium electrolyser are widely used abroad, but domestic technology is relatively backward, resulting in high power consumption and chlorine consumption. In recent years, the new factories in China have gradually adopted advanced large-scale electrolytic cell, which has improved the production technology and reduced the cost .

The price of raw material titanium sponge in 2005 and 2006 reached 200,000 yuan/ton. In the later stage, technical bottlenecks were broken through in raw materials, chlorination, refining and electrolysis of titanium sponge production. About 2017, the price of titanium sponge was adjusted all the way to 80,000 yuan/ton.Until 2024, the price of titanium sponge shows a trend of "high open and low go" . Titanium sponge prices are high at the beginning of the year, but with market supply and demand changes, the price gradually fell. Up to now, the price of titanium sponge has fallen by about 50,000 yuan/ton, which has fallen to a new low in history.

Even at the lowest point, the price of titanium sponge is still 50 yuan /kg. Because sponge titanium is expensive titanium and titanium alloys are expensive. The production and refining process of titanium sponge is very complex, and the production process also requires high temperature and high energy consumption equipment and vacuum environment, and the increase in energy costs directly affects its high price. That keeps the price of titanium high.