As we all know, titanium is a highly chemically active metal, it is easy to be oxidized in the air to produce titanium oxide, and the melting point of titanium is quite high, 1860 ° C, which makes the smelting process of titanium very difficult.

How to ensure the high purity of titanium, you have to find an inert gas, so argon began to perfectly combine with titanium.

Argon (high purity 99.995%) is an inert gas, at room temperature and other substances do not react chemically, at high temperatures are not soluble in liquid metals, in the welding of non-ferrous metals can show its superiority.

In the entire process of titanium and titanium alloy processing, argon is the emergence of a protective god, mainly in the following aspects:

Preparation of a titanium electrode

The welding process uses argon as a shielding gas during electrode preparation. Because the electrode is prevented from reacting with oxygen, argon and hydrogen in the air during the welding process, oxygen and hydrogen are added.

Smelting of dititanium and titanium alloys

Vacuum melting (VAR) is a kind of vacuum melting technology that uses arc as heat source to melt metals under vacuum conditions. Argon is used to fill the crucible to protect the titanium ingot during the cooling period of the titanium ingot (also called feeding), to prevent the reaction of titanium with the oxygen and nitrogen in the crucible at high temperature, resulting in the chemical composition of the titanium ingot exceeding the standard

Trititanium and titanium alloy heat treatment process

Physical and chemical stability of argon shielding materials. During the heat treatment of titanium and titanium alloys, the furnace is filled with argon gas. Prevent titanium and titanium alloys from reacting with oxygen in the air at high temperatures, leading to oxidation or corrosion.

Surface treatment of titanium and titanium alloys

Gas is also used for surface treatment of titanium and titanium alloys, such as plasma spraying under the protection of argon, which can improve the biological activity and mechanical properties of titanium surfaces. For example, in actual processing, it was found that the titanium alloy surface modified layer under the protection of argon has higher hardness and lower residual stress, which indicates that argon can effectively protect the material from oxidation and mechanical damage.

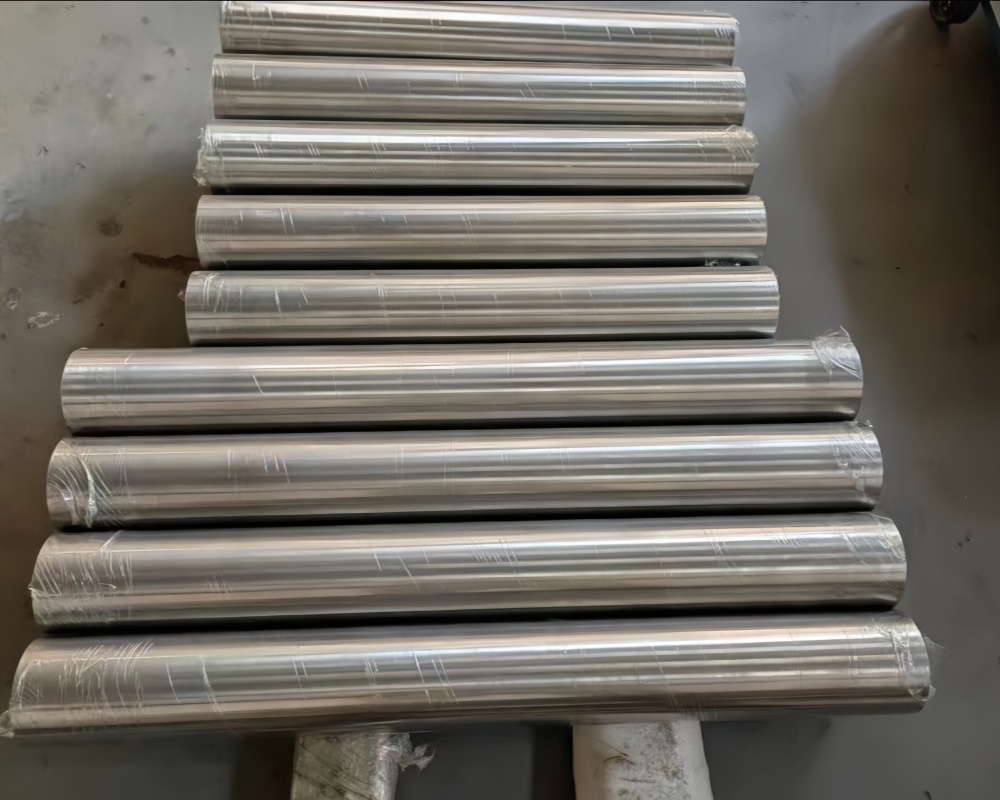

With the extensive use of argon, in order to reduce the transportation cost of argon and maintain the consistency of the argon process, Umingda Metal Materials has now established a centralized gas supply station. And it has been safely operated, and each station does not need to set up a separate gas cylinder.

It is necessary to maintain high purity argon in the production and preparation of titanium and titanium alloys, so it is very necessary to use argon for inert protection. Argon can prevent the reaction between titanium and oxygen and nitrogen in the air, and ensure the production of high purity titanium and titanium alloy materials, which has a wide range of application prospects.