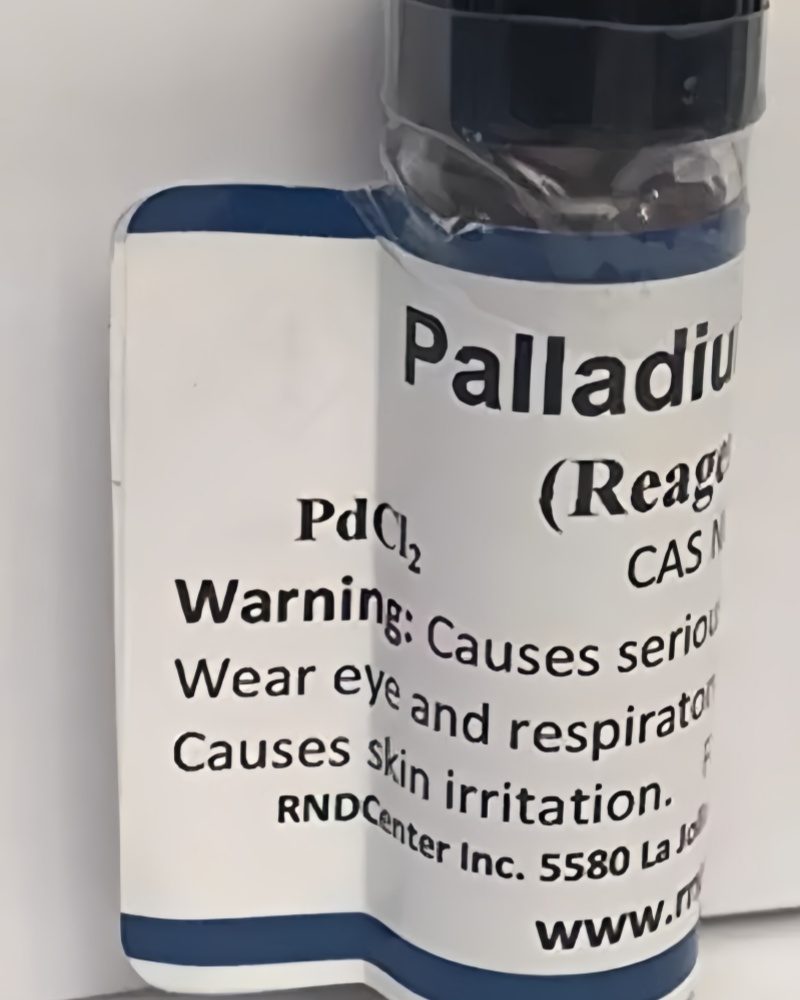

I first heard about palladium when I was studying the periodic table. Only know Palladium (Palladium), is the fifth cycle Ⅷ group platinum element, element symbol Pd. Palladium was discovered in 1803 by the British chemist Wullaston from the platinum ore, is one of the indispensable key materials in aerospace, aviation and other high-tech fields and automobile manufacturing. The name comes from Pallas, the Greek goddess of wisdom.

The first palladium was seen around 2015. The customer required the production of titanium palladium alloy Gr7 materials, only to know that titanium palladium alloy. Gr7 is a typical titanium-palladium alloy relative to the domestic grade TA9. Titanium palladium alloy TA9(Gr7) chemical composition: titanium (Ti) margin, 0.12≤ palladium (Pd)≤0.25. Nitrogen (N)≤0.03, carbon (C)≤0.08, hydrogen (H)≤0.013, iron (Fe)≤0.250, oxygen (O)≤0.15 TA9 titanium alloy is an alpha-type titanium alloy that is mechanically and physically equivalent to TA2 grade, except for the addition of the gap metal palladium, which makes it an alloy.

Different component content can be subdivided into high target and low palladium. TA9 has the best crevice corrosion resistance in various chloride-containing media at high temperature and high concentration, and also has various properties similar to those of various grades of industrial pure titanium, which is the strongest corrosion resistance in all titanium alloys. The TA9 class is used in the chemical industry and production equipment components. Compared with the annual corrosion rate of GR1 and GR2 industrial pure titanium in 5% boiling sulfuric acid 48.26mm/a, the corrosion rate of this titanium palladium alloy containing 0.2% palladium under the same working condition is only 0.508mm/a, a difference of nearly 100 times.

TA9(Gr7) titanium palladium alloy not only has high melting point, non-magnetic, low coefficient of thermal expansion, high specific strength and specific stiffness, but also has good corrosion resistance, biological erosion resistance and many other excellent properties.

High temperature strength: At temperatures up to 500C, TA9 titanium alloy can still maintain a high tensile strength, usually above 600 MPa.

Good corrosion resistance: TA9(Gr7) titanium palladium alloy works in humid atmosphere and seawater medium, and its corrosion resistance is far better than stainless steel; Resistance to pitting corrosion, acid corrosion, stress corrosion is particularly strong; Excellent corrosion resistance to alkali, chloride, chlorine, sulfuric acid, etc. However, the corrosion resistance of reducing oxygen and chromium salt media is poor.

Good low temperature performance :TA9(Gr7) titanium palladium alloy can still maintain its mechanical properties at low and ultra-low temperatures.

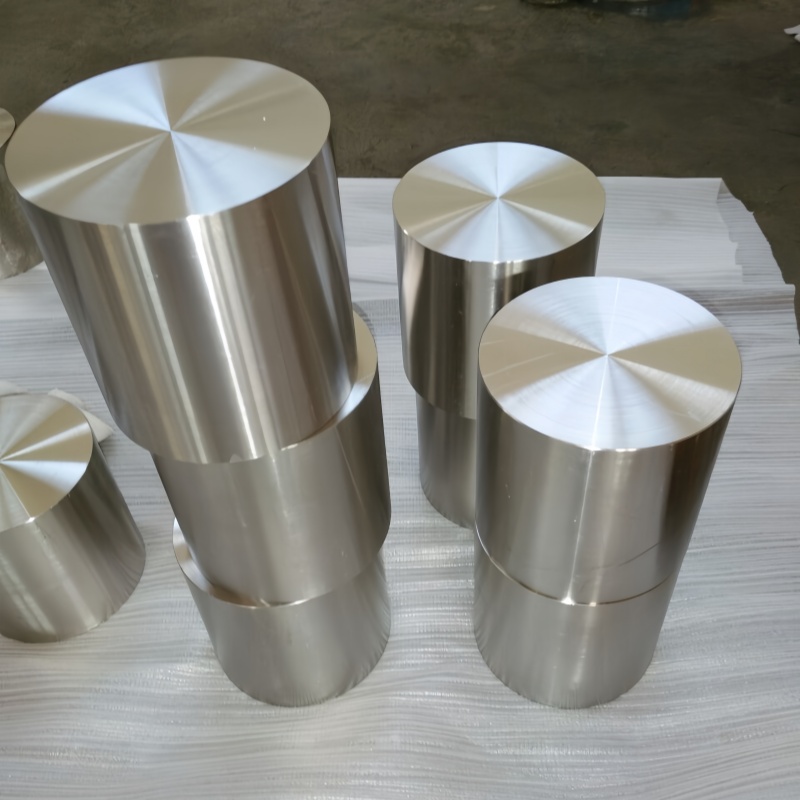

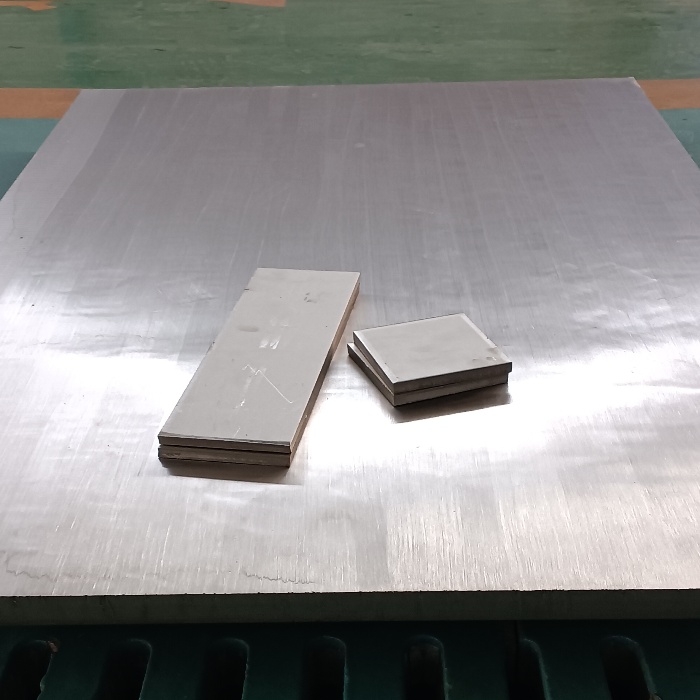

The alloy has good machining, forming and welding properties. Because of the application of the precious metal palladium, the cost is higher than that of pure titanium. Matching welding materials ERTi-0.2Pd, ERTi-7. Supply form sheet, strip, bar, pipe (welded pipe and seamless pipe), wire, forging, light rod, flange, etc.

TA9 titanium alloy is widely used in the following fields: aerospace industry: for the manufacture of engine parts, turbine blades and other high-temperature structural parts. Shipbuilding: Suitable for environments where seawater corrosion is severe, such as desalination equipment and Marine engineering.