Hardness, a technical term in physics, the ability of a material to locally resist hard objects pressing into its surface is called hardness. The local resistance of solid to the invasion of external objects is one of the important performance indicators of metal materials. Generally, the higher the hardness, the better the wear resistance. Commonly used hardness indicators are: Brinell hardness test (HB), Rockwell hardness test (HRC) and Vickers hardness test (HV).

Rockwell hardness (HRC) test method is to use a diamond cone with a top Angle of 120 degrees or a steel ball with a diameter of 1.5875mm/3.175mm/ 6.35mm/12.7mm, pressed into the surface of the material to be measured under a certain load, and the hardness of the material is obtained from the depth of the indentation. The three most commonly used scales are A, B, C, that is, HRA, HRB, HRC, according to the hardness of different experimental materials, choose different hardness ranges of scales to indicate:

HRA is a hardness obtained by using a 60Kg load and a diamond cone indenter for materials with higher hardness. For example: steel sheet, carbide.

HRB is a hardness obtained by using a 100Kg load and a hardened steel ball with a diameter of 1.5875mm for materials with lower hardness. For example: mild steel, non-ferrous metal, annealed steel, etc.

HRC is a hardness obtained by using a 150Kg load and a diamond cone indenter for materials with higher hardness. For example: hardened steel, cast iron, etc.

Brinell Hardness Test (HB)

The hardened steel ball with diameter D is pressed into the surface of the measured metal material with a certain amount of load P, and the load is removed after being held for a period of time. The ratio of the load P to the indentation surface area F is the Brinell hardness value, denoted HB.

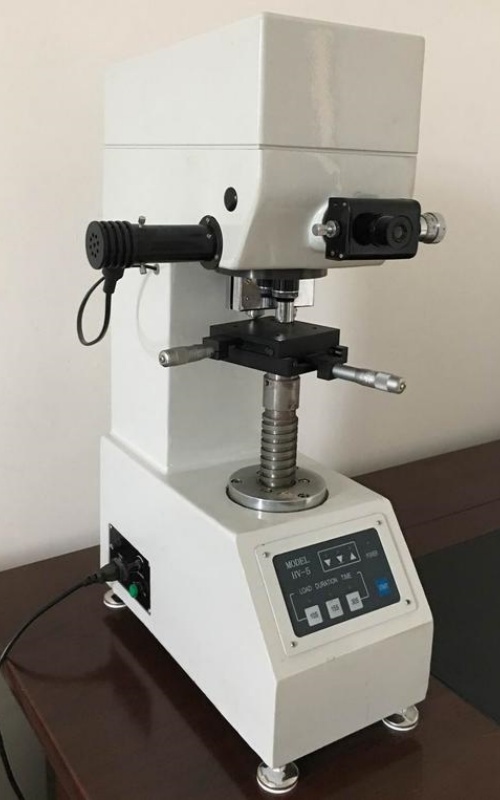

Vickers Hardness Test (HV)

It means that a diamond regular pyramid indenter with an Angle of 136 degrees between the relative surfaces is pressed into the surface of the tested sample under the specified load F, and the load is removed after a fixed time, and the diagonal length of the indentation d is measured, and then the indentation surface area is calculated, and the average pressure on the indentation surface area is calculated, that is, the Vickers hardness value of the metal is expressed by the symbol HV. In the actual measurement, there is no need to calculate, but according to the measured d value, directly look up the table to get the measured hardness value.

The hardness range of titanium alloys varies due to factors such as alloy composition and heat treatment process. In general, the hardness HRC of titanium alloy (annealed) is roughly between 32-38. At room temperature, the hardness of titanium alloy is about 33 to 35HV, and it can reach about 250 to 350HV after heating. If you do some brushing on the surface of titanium alloy, the hardness can probably reach 68HV.

Although the hardness of titanium alloy is not particularly high, its strength is much higher than that of stainless steel, and it has low density and high heat resistance, so it is widely used in aerospace, medical sports and other fields.

The common hardness range of TC4 titanium rods is HB269-351,(HRC)30.80----40.70

TC4 titanium plate common hardness range HRC32.80-36.80(HB286-311)

Common hardness range of pure titanium plate HV140-150

The common hardness range of pure titanium rods is HV159--226

The common hardness range of pure titanium tubes is HV150-200

The common hardness range of GR2 titanium forgings is HB130-250