Titanium alloy is a kind of metal material with excellent properties, widely used in aviation, aerospace, chemical, petroleum, electric power, medical, construction, sporting goods and other fields.

In the processing of titanium alloy, welding process is an indispensable processing technology. Titanium material is very active, because titanium alloy is easy to react with oxygen, nitrogen, hydrogen and other elements in the air at high temperatures, resulting in a decline in weld quality and deterioration in performance, so it can not be welded by the usual method. All titanium materials need to be protected by inert gas before welding.

TC4(T-6A1-4V) titanium alloy is one of the most widely used titanium alloys. It accounts for about 50% of the titanium alloy used in the aerospace industry.

Titanium alloy commonly used welding methods are: tungsten argon arc welding process, molten argon arc welding process, plasma welding process, electron beam titanium alloy welding process.

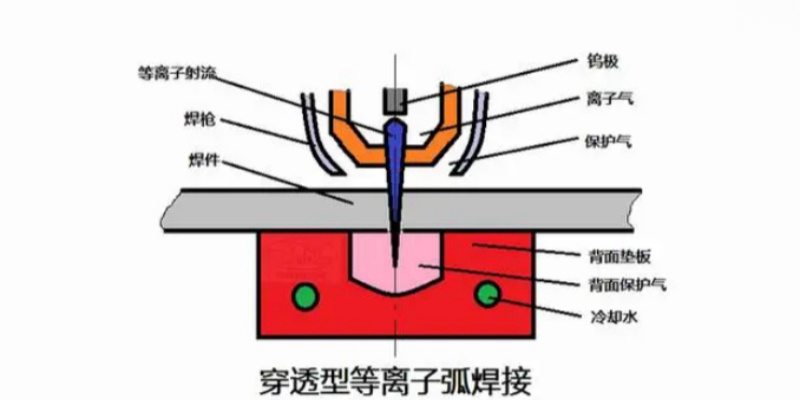

Today we mainly talk about the plasma welding process. Plasma arc welding (PAW) : This is an arc welding method using high temperature and high speed plasma arc as a heat source, which is suitable for the butt, Angle and lap welding of titanium and titanium alloy plates, pipes and special-shaped parts with a thickness of 0.5~15mm. The advantages of this method are that it can be carried out in the atmosphere, only need to be protected by blowing inert gas back and forth, and the weld depth to width ratio is large, the deformation is small, and the efficiency is high. The disadvantage is that the equipment is more complex, and the parameters of the nozzle aperture, ionic gas flow, welding speed and other requirements are higher, and it is not suitable for the workpiece with curved surface or variable cross-section.

The main difficulties of titanium alloy welding:

1 embrittlement phenomenon: Titanium alloy is easy to react with impurities such as oxygen, nitrogen and hydrogen in the atmosphere at high temperatures, resulting in embrittlement of welded joints, reducing their plasticity and toughness. To avoid this phenomenon, it is necessary to strictly control the welding atmosphere and the purity of the material.

2 Welding cracks: The generation of cracks is closely related to stress and hydrogen content. Therefore, it is necessary to control the stress during the welding process, avoid overheating and rapid cooling of the material, and ensure that the welding area is dry and clean.

3 Welding porosity: The reaction of titanium alloy with oxide is easy to produce porosity, which affects the strength and sealing of welded joints. By controlling the oxygen content of argon shielding and welding materials, as well as ensuring that the welding area is dry and clean, the formation of pores can be effectively reduced.

In order to prevent defects in titanium alloy welding, the following measures should be taken:

1 Choose the appropriate welding process and wire: according to the material and impurities of the titanium alloy base metal, choose the appropriate welding method and wire.

2 Use high-quality protective gas: ensure that the purity is not less than 99.99% to ensure the protection of the welding area.

3 Cleaning and treatment before welding: thoroughly clean and treat the base metal and welding wire to avoid cracks and interlayers.

4. Take appropriate protective measures: In the welding process, argon gas protection is carried out on the heat affected area of the weld pool to ensure welding quality.

Finally, the quality control of titanium alloy welding is a very important part of the welding process, including joint morphology, porosity, cracks, deformation and so on. The weld shape should be uniform. Smooth, no porosity, cracks and other defects, welding joint deformation should be controlled within a reasonable range. In order to ensure the welding quality, it is usually necessary to carry out welding process evaluation and welding process test to determine the best welding process parameters and control measures.

In summary, titanium alloy welding is a complex process, considering the material characteristics, welding methods, welding parameters, gas protection and quality control and other factors. Only by mastering the correct welding methods and technologies can we ensure the quality and performance of titanium alloy welded joints and meet the requirements of titanium alloy materials in different fields.