Titanium material is an important metal material, widely used in aviation, aerospace, ocean and other fields. Sand blasting is one of the common surface treatment methods.

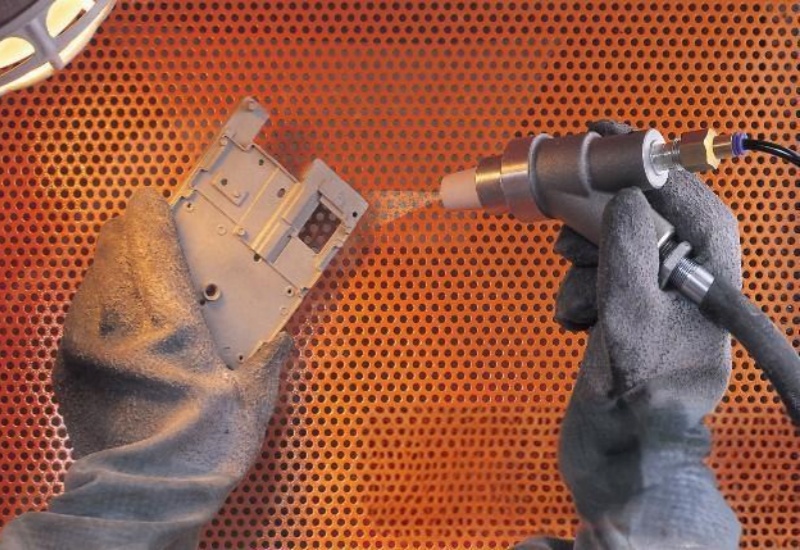

Sandblasting treatment: compressed air is used as the power to form a high-speed jet beam to spray the spray material (quartz sand, emery, iron sand, sea sand) to the surface of the workpiece to be treated at high speed, and the appearance or shape of the workpiece surface changes. The surface of the workpiece obtains a certain degree of cleanliness and different roughness, and the mechanical properties of the workpiece surface are improved, so the fatigue resistance of the workpiece is improved, the adhesion between it and the coating is increased, the durability of the coating is extended, and the flow and decoration of the coating are also beneficial.

Titanium sandblasting has the following purposes.

1 Machining burr cleaning and surface beautification. For example, the residual oxidation layer, sintering layer, porosity, burr and other defects of the previous process.

2 Improve the mechanical properties of parts. For example, improving the surface roughness and increasing the surface activity is conducive to the subsequent surface treatment process.

3 Decorative effect. For example, beautify the appearance of the product to ensure the integrity and finish of the titanium alloy surface.

4 Stress relief and surface strengthening. For example, by hitting the surface of the workpiece with sand balls, the stress is eliminated and the surface strength of the workpiece is increased.

Important influencing factors in the production of titanium material sandblasting. Gravel material and mesh number, gas pressure, sand flow rate and blasting time are the most important parameters that affect material cutting quality.

1 Titanium material sandblasting generally choose white corundum sandblasting 24 mesh 36 mesh 46 mesh 54 mesh 64 mesh sandblasting.

2. The sand blasting pressure of titanium material is controlled at 0.3-0.6MPa.

3. The blasting time is verified according to the product size, area, and final effect.

4 Control the sand blasting distance and Angle. Generally, the sandblasting distance is controlled at 20-30cm, and the sandblasting Angle is generally 45 degrees.

Precautions for titanium sandblasting:

1 You must wear protective equipment before work, and the work site shall not be less than two people.

2 Gas storage tank, pressure gauge, safety width should be checked regularly.

3 Start the ventilation and dust removal equipment before work, and prohibit the sand blasting machine from working.

4 After the work is finished, the ventilation and dust removal equipment should continue to run for five minutes before closing, in order to discharge indoor dust and keep the site clean.

In short, titanium sandblasting is a common surface treatment method, which can improve the surface finish and corrosion resistance of titanium materials. It is necessary to pay attention to the selection of sandblasting materials and the control of air pressure during sandblasting according to the actual situation to ensure that the requirements of titanium products are met.