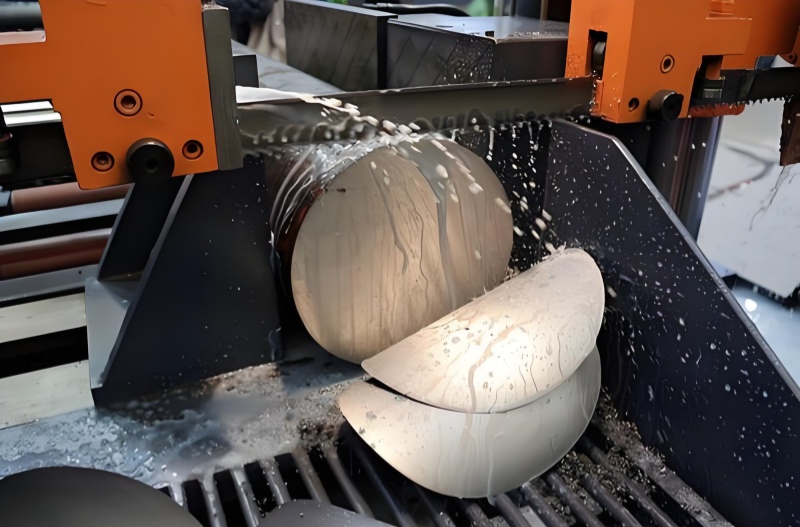

Titanium and titanium alloy processing is more sensitive to temperature and is more difficult to process in metal materials, for the cutting of titanium alloy is usually cut with cold sawing, heat dissipation and good, sawing stability, can be quickly cut, but also to ensure that its section is smooth when cutting, no burrs.

According to the machining process and the metal characteristics of titanium and titanium alloy, titanium alloy has the following cutting characteristics:

1. Small deformation coefficient: the deformation coefficient is less than or close to 1. The path of sliding friction of chips on the front tool face is greatly increased, which accelerates the wear of band saw blade.

2. High cutting temperature: Because the thermal conductivity of titanium alloy is very small (only equivalent to 1/5 ~ 1/7 of No. 45 steel), the contact length between the chip and the front tool surface is very short, and the heat generated during cutting is not easy to be transmitted, concentrated in a small range near the cutting zone and cutting edge.

3. Large cutting force per unit area: the elastic modulus of titanium alloy is small, and it is easy to bend and deform under the action of radial force during processing, causing vibration, increasing band saw blade wear and affecting the accuracy of parts.

4. Serious cooling phenomenon: due to the large chemical activity of titanium, at high cutting temperatures, it is easy to absorb oxygen and nitrogen in the air to form a hard and brittle skin.

5. Band saw blade tip is easy to wear: after the blank is processed by stamping, forging, hot rolling and other methods, it forms a hard and brittle uneven skin, which is easy to cause the breaking edge phenomenon, making the cutting of hard skin a difficult process in titanium alloy processing.

The choice of saw blade.

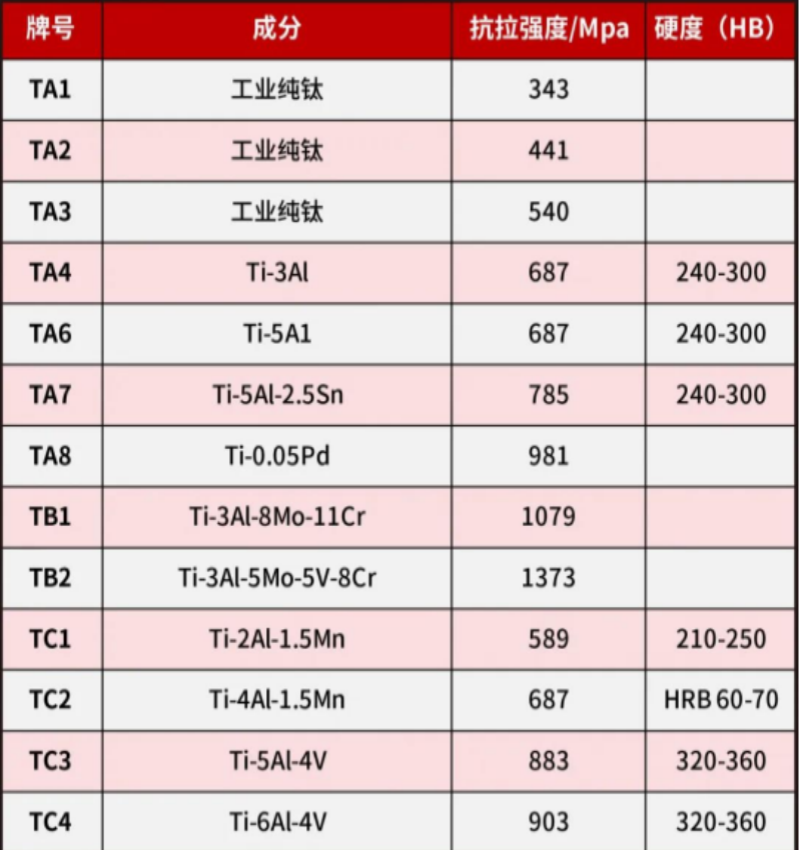

Choose different types of saw blades for different titanium properties.

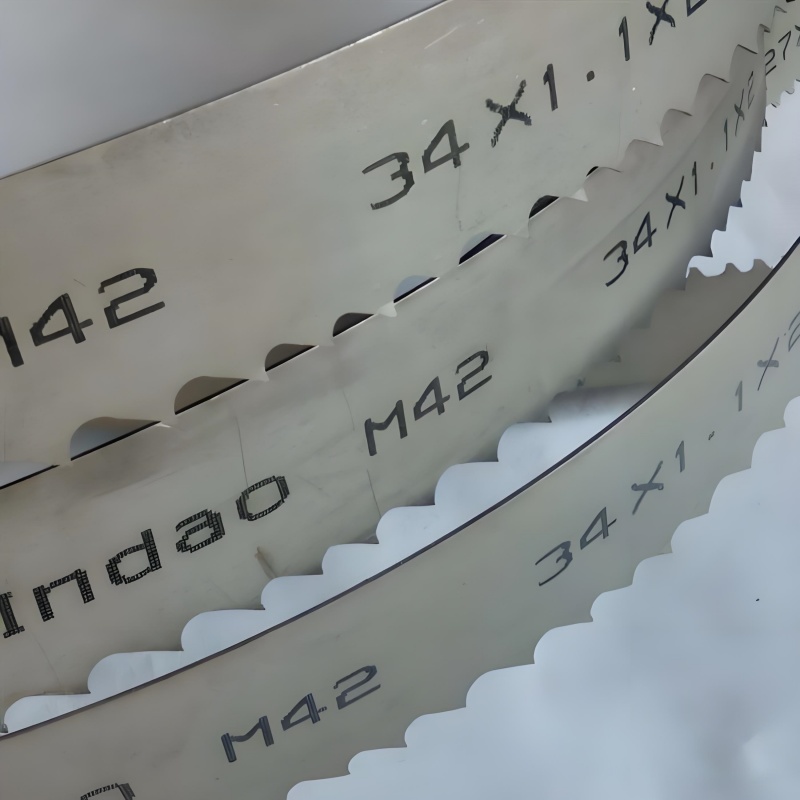

Pure titanium (GR2) Select bimetal band saw blade. For the grinding type band saw blade, it can reduce the friction of chips on the front tool surface, and the latter is the high-low tooth type band saw blade, which can reduce the cutting force, high tool accuracy and good back strength.

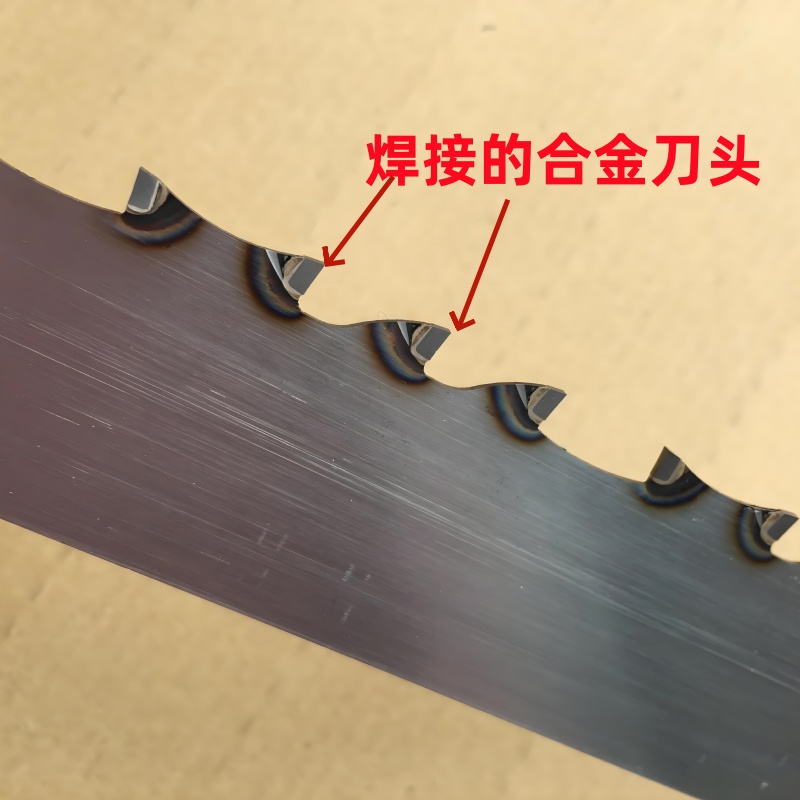

Titanium alloy (GR5) Select a segmented carbide band saw blade. Used for sawing titanium alloys with hardness below 36HRC.

Sawing important parameter setting:

Band saw speed setting: Different grades of cut materials, different specifications, different heat treatment states and different saw machine performance will affect the band saw speed setting. The larger the material, the line speed should be appropriately reduced.

Running-in of new saw blade: Because the cutting edge of the new saw blade is too sharp, the running-in procedure needs to be performed. The running-in of the bimetal band saw blade is generally to reduce the feed speed to half of the normal value, while the running-in of the cemented carbide band saw blade is to reduce the line speed by half (if it is the lowest, then do not reduce it), and then adjust the feed to about 1/4 of the normal value and slowly rise.

Feed speed: Too fast feed speed is easy to cause oblique cutting or tooth pulling, too slow feed may also cost the saw blade or cause the sawing machine operating efficiency is too low.

Clamp the jaws correctly: try to clamp the jaws tightly and clamp correctly. If the clamping method of steel pipe is wrong, it is easy to cause the gear failure.

Coolant: plays the role of cooling, lubrication and cleaning. The sawing was done at 5% concentration. Carbide band saw with gold material, it is recommended to increase the cutting concentration to 10%. High speed sawing of non-ferrous metals generally adopts micro-lubrication, but attention should be paid to the selection of the grade and type of micro-lubricating oil.

For an excellent titanium and titanium alloy manufacturing enterprise, sawing is a very important link. Enterprises can have good benefits. Judging from the sawing process. The service life of saw blade, the classification and placement of saw blade head, the accuracy of cutting weight, etc.