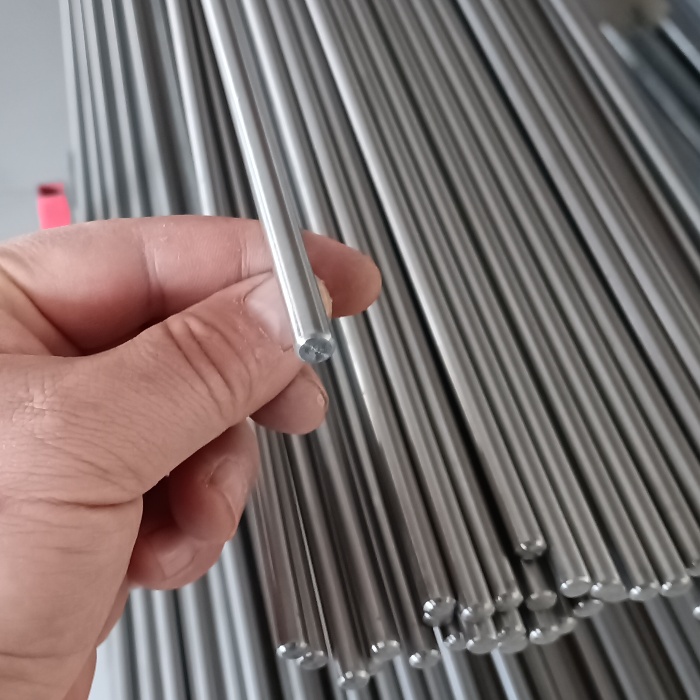

Titanium rods are the most commonly used titanium alloy materials. How to process the appearance of smooth, precision H11, H9, H8, H7 titanium rod.

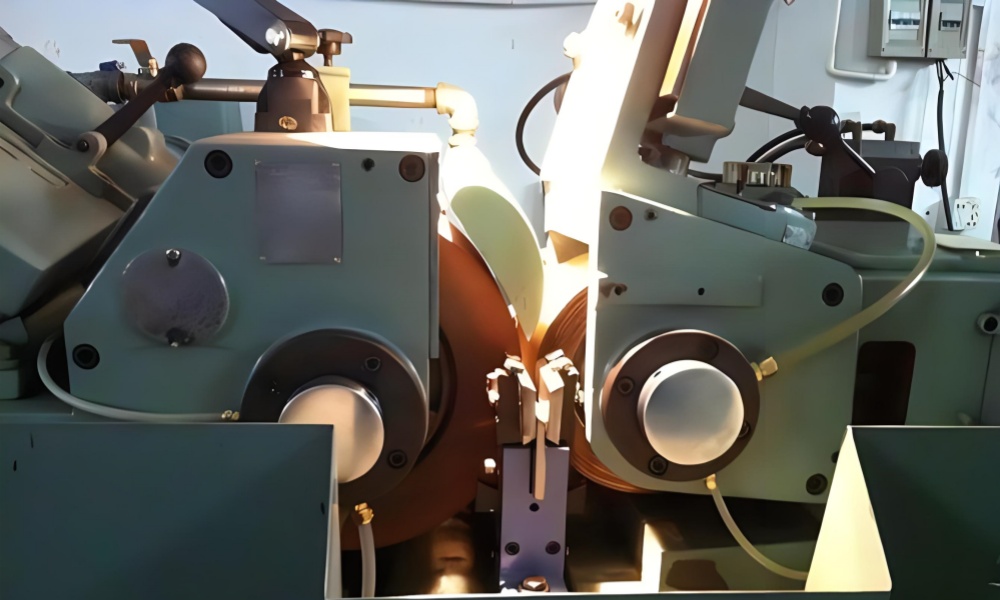

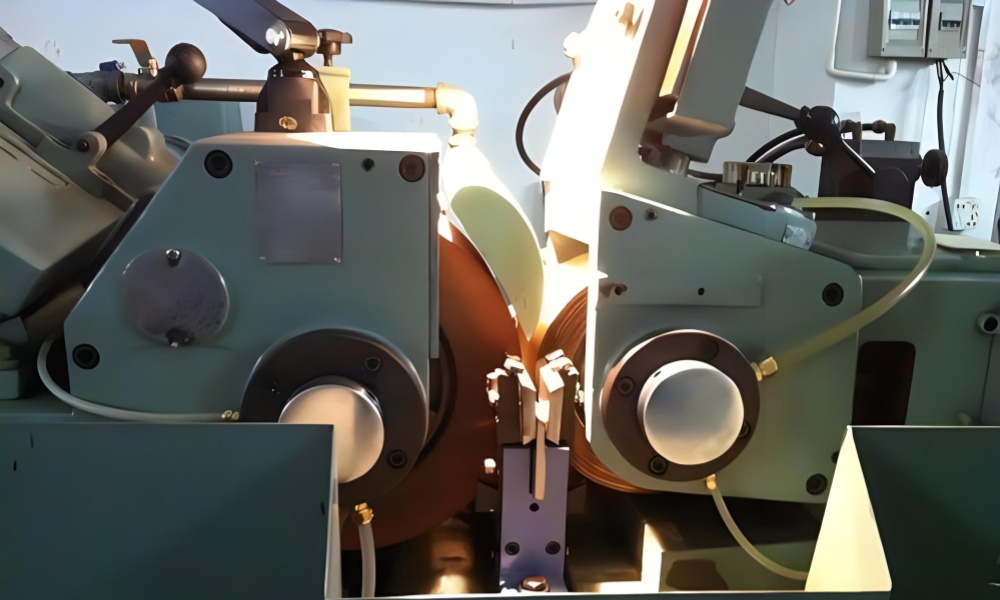

Then you have to say: centerless grinder. Centerless grinding machine is a kind of grinding machine that does not need to use the axis positioning of the workpiece. It is mainly composed of three mechanisms: grinding wheel, adjusting wheel and workpiece support. The grinding wheel actually serves as the grinding work, the adjusting wheel controls the rotation of the workpiece and controls the feed speed of the workpiece. These three parts can be processed in several ways.

According to the characteristics of titanium alloy materials, grinding has the following five characteristics.

1, high hardness

As a high-strength material, titanium alloy has a high hardness, usually between HV350 and 400. This also leads to titanium alloy grinding, grinding tools often appear loss, break and so on.

2, low thermal conductivity

The thermal conductivity of titanium alloy is very low, much lower than that of conventional materials such as steel. In titanium alloy grinding, heat will accumulate in the grinding area in a short period of time, resulting in cutting fluid is not easy to discharge, easy to cause the problem of poor grinding surface quality.

3, susceptible to oxidation

Under high temperature and pressure, titanium alloy material is easy to oxidize, resulting in poor surface quality and difficult processing. Therefore, when grinding titanium alloys, it is necessary to use a suitable grinding fluid to strengthen cooling and lubrication and reduce the risk of oxidation.

4. The tool is easy to bond and wear. During the contact between the grinding wheel and titanium alloy material, the friction causes high temperature, which will cause deformation of the titanium alloy, adhesion to the grinding wheel or the abrasive particles are removed and the grinding wheel is damaged.

5 The system is chilled. The chemical activity of titanium element is strong, the high temperature environment produced by grinding, the skin of titanium alloy material chemical reaction, not only the alloy elasticity is reduced, but also the surface hardening, the processing process is more complex, will reduce the fatigue strength of the parts.

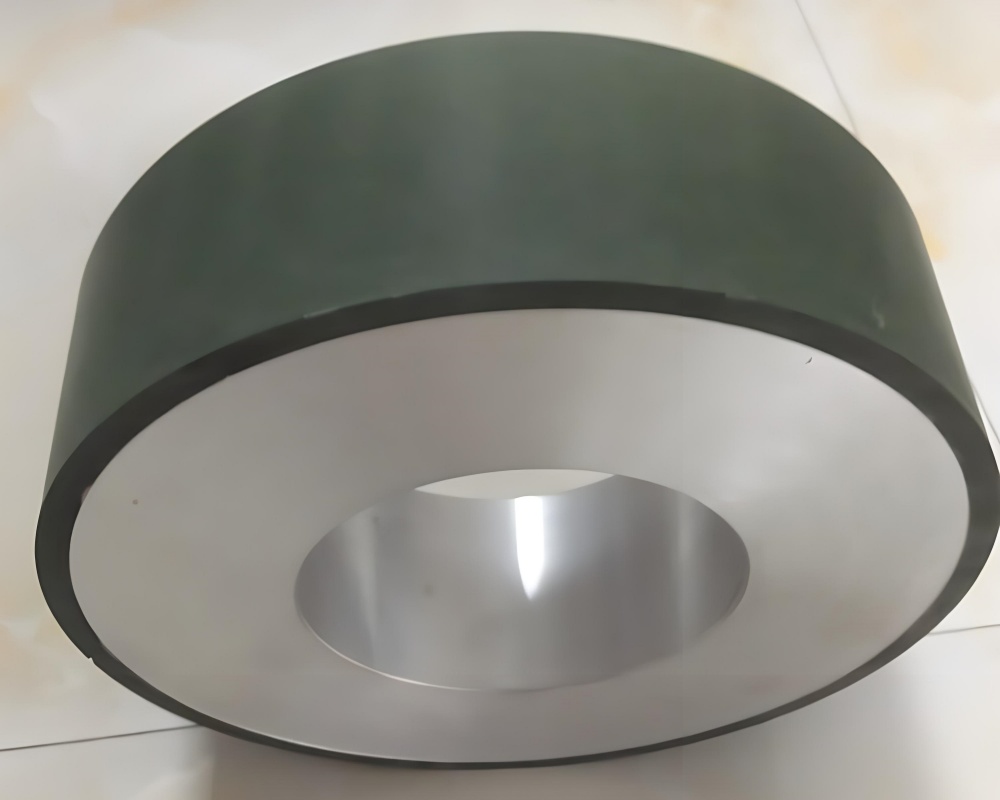

Choice of grinding wheel

1 Silicon carbide grinding wheel. The silicon carbide grinding wheel has high hardness and low wear, which can effectively reduce the grinding temperature and ensure the grinding quality.

2 cubic boron nitride not only has high hardness, but also can withstand high heat, which is used in many enterprises; The use of polycrystalline diamond can adapt to the requirements of high heat and high speed in the grinding of titanium alloy, and its stability is good, and it is also widely used.

Titanium alloy grinding machine coolant requirements.

To take away the heat quickly. The grinding fluid is used during the machining of the centerless grinder. In addition to the cooling effect, there is a washing effect of fine sand on the surface of the product. Clean the residue on the surface of the grinding wheel, and use the high-pressure cleaning device to clean the adhesion on the surface of the grinding wheel in time, which is helpful to reduce the positioning error. Water-soluble grinding fluids containing a variety of extreme pressure additives should be selected.

The key grinding parameters of titanium alloy grinding, such as the appropriate feed rate, speed, etc.

According to our experience for TC4φ10 titanium rod as an example, the best grinding depth is 0.05~0.1mm, the best grinding wheel speed is 25m/s, the grinding wheel adhesion rate is the smallest, the best grinding surface.

Titanium alloy material has a broad application market. With the wider application range of titanium alloy materials, when grinding titanium alloy materials, only by constantly improving the process and optimizing the equipment and instruments can we obtain high-precision and high-performance titanium alloy bars.