Sponge titanium is a raw material for processing titanium and titanium alloy materials. The product should be light gray or silver gray spongy, clean surface, no visual inclusions visible, can allow some defective sponge titanium block.

From the discovery of titanium to the first production of more pure metal titanium has experienced 120 years of history. In 1947, the United States took the lead in the industrial production of titanium sponge, with a output of 2 tons that year; Japan began the industrial production of titanium sponge in 1952 and the Soviet Union in 1954. In 1955, China began the research of titanium, in November 1955, the Ministry of heavy Industry in the non-ferrous metal Comprehensive Research Institute with magnesium reduction method successfully produced a purity of 99.3% sponge titanium.

The production of titanium sponge generally uses the Kroll method, also known as magnesium thermal method, and its production process mainly includes rich material preparation, chlorination, titanium tetrachloride refining, reduction distillation, and magnesium chloride electrolysis. It is simply understood that ilmenite is changed into titanium tetrachloride, and then put into a sealed stainless steel tank, filled with argon, so that they react with metal magnesium, and get "titanium sponge".

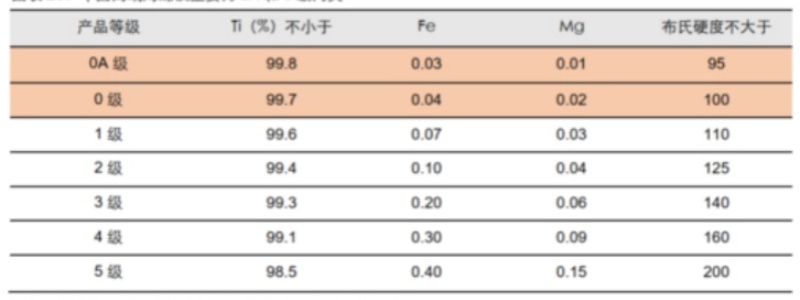

The current national unified implementation standard of titanium sponge: GB/T2524-2019. Titanium sponge products are divided into 7 grades (grades) according to chemical composition and Brinell hardness :MHT-95(grade 0A), MHT-100(grade 0), MHT-10(grade 1), MHT-125(grade 2), MHT-140(grade 3), MHT-160(grade 4), and MHT-200(grade 5).

Titanium content ranges from 98.5 to 99.7, and the smaller the number, the higher the titanium content. We can usually hear the titanium content of 99.6 refers to the purity of grade 1 sponge titanium, usually said the market price is generally based on grade 1.

The characteristic of titanium sponge is that after contact with air, the surface is easy to oxidize, which affects the quality. Therefore, it is necessary to use a good sealing plastic inner membrane, vacuum, plastic inner bag filled with argon, can withstand the pressure of metal container packaging.

China's sponge titanium production is mainly distributed in Liaoning, Panzhihua, Guizhou, Yunnan and Xinjiang regions. At present, the main production enterprises are Pangang titanium industry, double Ruiwanji, Guizhou Zun titanium, Longpython Baililian and other enterprises.