Recently, the Mi 14 Ultra was officially released, which brought a titanium special edition model. The middle frame is made of titanium Metal and metal Injection Molding (Metal Injection Molding) process.

MIM is metal powder injection molding, known as the fifth generation of metal molding process. It is a new type of near-net forming technology, which is considered as an ideal processing technology for preparing titanium and titanium alloys because of its mass production of complex structures, high dimensions and high precision parts at a lower cost.

MIM is different from other metal forming processes, somewhat similar to the plastic injection molding process, is the metal powder and binder first mixed to form a feed. Then injection molding, after which the binder is removed (degreasing process), high temperature sintering, post-processing. Before production, it is necessary to carry out product design, mold design and manufacturing, and then the process flow is shown as follows:

At present, the main feeding of titanium alloy refers to the uniform mixing of a certain titanium alloy metal powder and binder at a certain temperature in accordance with a certain proportion to obtain a powder and binder mixture suitable for injection molding. Uniform feed preparation is the key to obtain high precision powder injection molding products, if the feed mix is not uniform, the binder will be deformed during the degreasing process and the sintering shrinkage is not uniform, thus increasing the size deviation of the final sintered body. Therefore, the preparation of the feed plays a decisive role in the accuracy of the MIM product.

At present, the research of MIM titanium and titanium alloy has made certain progress, but there are still some difficulties in large-scale industrial application, mainly the following points:

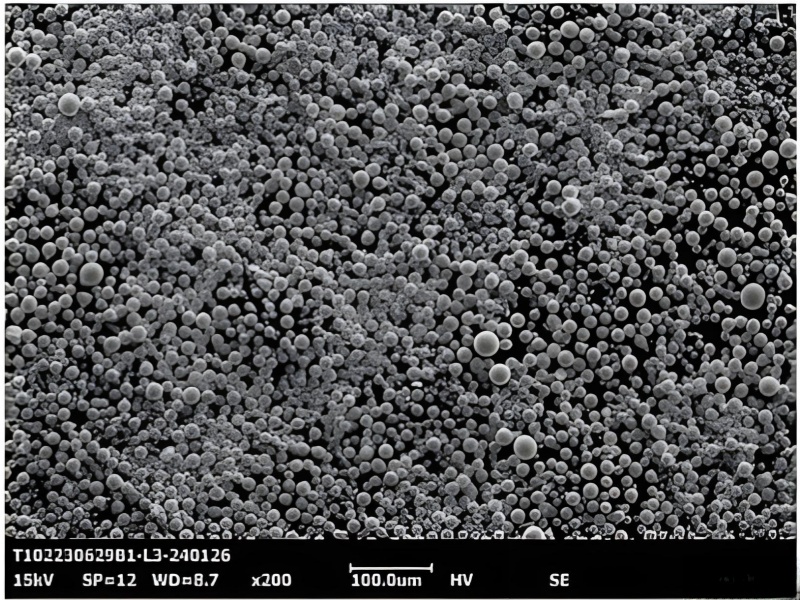

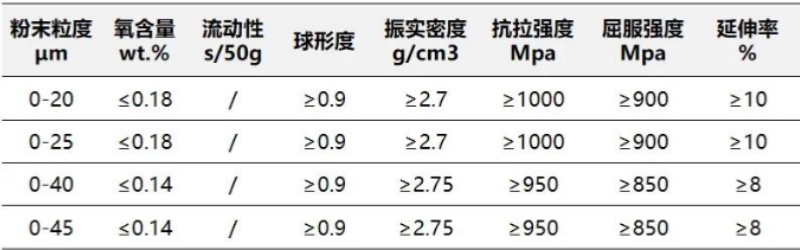

1. Low oxygen spherical titanium and titanium alloy powder are expensive. Domestic spherical titanium and titanium alloy powder manufacturers have developed rapidly in recent years.

2. Selection of binder and degreasing removal process; The choice of binder determines the size of the powder filling amount, which has a direct impact on the density, shrinkage and surface roughness of the sintered product, and the efficient degreasing removal process helps to reduce the influence of impurity elements, such as carbon and oxygen, and improve product performance.

3. Sintering process optimization and equipment requirements. Because of the high activity of titanium alloy, it is very important to control the temperature and oxygen content during sintering, which puts forward higher requirements for sintering furnace.

In the field of titanium materials MIM, the main focus is on titanium alloy powder and its feeding preparation. At present, pure titanium powder, Ti-6Al-4V, TiAl, Ti-Mo-Al and some other titan-based material powders have been successfully manufactured by injection molding process.