3D printing technology is an emerging industrial technology,which could provide accurate and rapid prototyping ,and shorten the development time of products. It has gained much attention. Due to the increasing demand for metal 3D printing in industrial vertical industries such as automotive, aerospace and defense, 3D printing will dominate the market in the future.

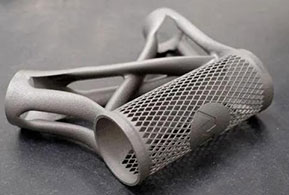

Metal 3D printing is a kind of technology that uses metal powder to print the metal parts directly, also known as metal powder sintering (SLM). The density of sintering metal parts can reach 99% of the casting density, with good strength and short lead time( the printing time is in 5-7 days).

3D printing titanium alloy parts are with very high strength, strong corrosion resistance, accurate size, light weight,and good biological compatibility, mainly used in lightweight structure and parts (such as aircraft engines, aircraft landing gear parts, automotive parts, etc.); orthopedic implants, surgical AIDS, surgical guide plate / precision instruments, etc.

Baoji Yumingda Metal Materials Co., Ltd. has been involved in the supply of additive manufacturing materials about 10 years . The popular material grade used in 3D printing filed ,has mainly Gr1,Gr2,Gr5,Gr23, Ti-10V-2Fe-3Al, Ti-6.5Al-1Mo-1V-2Zr(TA15),Ti-6.5Al-3.5Mo-1.5Zr-0.3Si(TC11)

Ti-5Al-5Mo-5V-1Cr-1Fe(TC18),including titanium bars, titanium wires ,titanium plates, titanium forgings. The available material specification : ASTM B348, ASTM B863,ASTM B265,ASTM B381, AMS4928,ASTM F67,ASTM F136 , MIL-T-9047G,etc.

TA15 Titanium Forgings for Additive Manufacturing

TC4/ Gr5 Titanium Bar for Additive Manufactuing